How Does A Laser Marking Machine Work – Why Can A Beam Of Light Engrave?

- Conocimientos, Noticias

- 90+ reading now

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

In modern industry and daily life, laser marking machines have long been everywhere. Whether it is the logo on the back of a mobile phone, the characters on a keyboard, or the numbers on hardware parts, many of them are inseparable from "laser marking." So, have you ever wondered: why can a seemingly soft beam of light engrave clear patterns and characters on hard metal or plastic? Today, let us uncover the secrets of laser marking machines.

Laser (Light Amplification by Stimulated Emission of Radiation) is essentially an electromagnetic wave with a single frequency, consistent phase, and extremely high directionality.

Industrial marking often uses near-infrared fiber lasers with a wavelength of 1064 nm, as well as CO₂ lasers at 10.6 μm, and ultraviolet lasers at 355 nm. Different wavelengths correspond to different photon energies: E=hc/λ. The energy of a single 1064 nm photon is about 1.17 eV, which is not enough to directly break most chemical bonds, but in an extremely short time and small space, the power density can be increased to 10⁶–10⁹ W/cm², instantly heating the irradiated area to a molten, vaporized, or even plasma state. This “energy concentration” is the core of laser processing.

The core principle of laser marking is to use a high-energy-density laser beam to perform “localized irradiation” on the surface of the material. When the laser instantly focuses on the surface of the material, the local temperature rapidly rises to thousands of degrees Celsius, causing the material to undergo vaporization, carbonization, or color change, thereby forming a permanent mark.

Non-contact processing: The laser only interacts with the material surface through energy, with no mechanical wear.

High precision: The laser focal spot is extremely small, reaching micron-level precision, suitable for the processing of tiny parts.

Permanent marking: Not easy to wear off, resistant to high temperature and corrosion, suitable for long-term traceability in the industrial field.

It can be said that laser marking is an advanced technology of “replacing a blade with light.”

Laser marking machines are not of a single type. Lasers of different wavelengths and structures are suitable for different materials. The common types are:

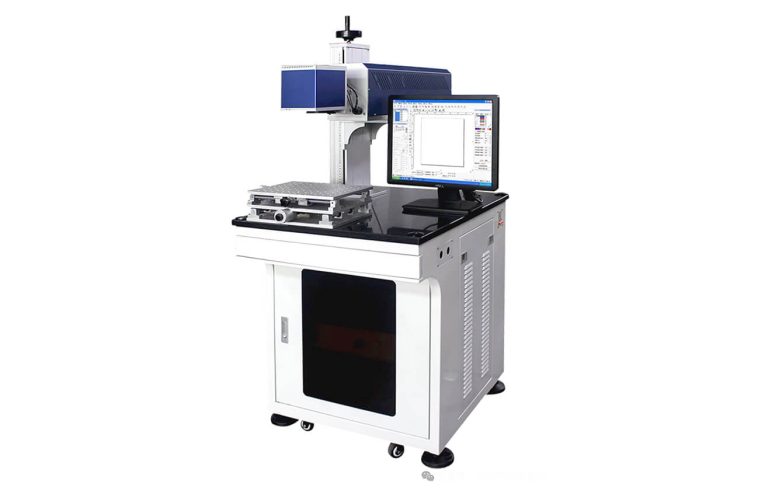

Fiber lasers use rare-earth-doped fibers as the gain medium to output near-infrared lasers. By combining with high-speed scanning galvanometer systems, they can achieve precise marking.

Applicable materials: Most metals and some non-metals, such as textiles, leather, glass, polymers, electronics, hardware, jewelry, tobacco, etc.

Common power levels: 20W, 30W, 50W, 70W, 100W, 120W.

Advantages: Excellent beam quality, very small spot size, extremely fine marking; high marking precision, fast speed, especially outstanding performance on metals; high electro-optical conversion efficiency, maintenance-free, long service life.

Aplicaciones: Metal nameplates, electronic shells, automotive parts traceability codes, medical instruments, tools, etc.

CO₂ lasers use gas discharge to generate a wavelength of 10.6 μm, belonging to far-infrared lasers. With relatively high power, they are mainly used in non-metal material processing.

Applicable materials: Paper, leather, wood, plastics, acrylic, fabrics, rubber, ceramics, glass, artificial stone, crystals, jade, etc.

Common power levels: 10W–275W.

Advantages: High-quality output, clear marking, not easy to copy or modify, high speed, flexible operation, energy saving, environmentally friendly.

Aplicaciones: Food packaging dates, batch numbers, wood carving, acrylic signs, leather marking, glass engraving, etc.

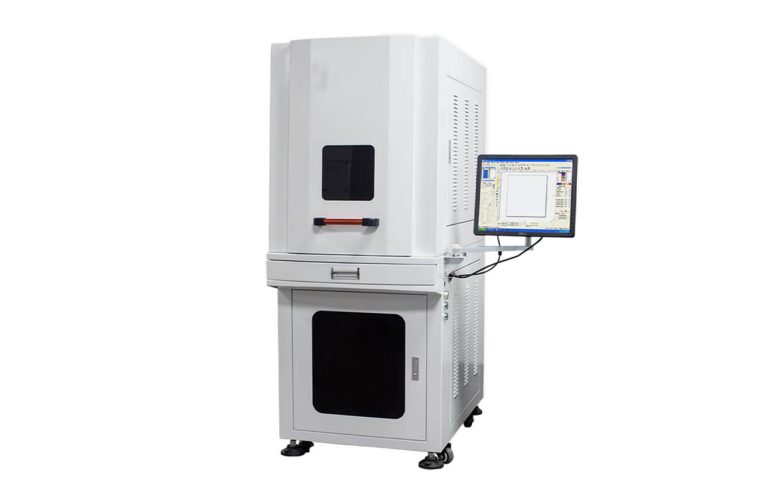

Ultraviolet lasers use third-harmonic generation technology (THG) to obtain 355 nm wavelength UV light. Compared with infrared lasers, UV has higher photon energy, and the “cold processing” effect achieved by photochemical ablation greatly reduces thermal influence.

Applicable materials: PCB, silicon wafers, glass, sapphire, ceramics, electronic components, medical equipment, mobile phone motherboards, etc.

Common power levels: 3W, 5W, 10W, 15W. Among them, 3W–5W models are widely used in industry, with a balance of cost and performance.

Advantages: Ultra-fine marking, minimal heat-affected zone, high contrast, suitable for almost all materials, especially for high-end, precision, and special material processing.

Aplicaciones: Micro QR codes, mobile phone buttons, packaging, glassware, FPC, PCB, etc.

During laser marking, both the fuente láser and the galvanometer system generate significant heat. Without proper cooling, this leads to:

Reduced laser power; Unstable beam quality; Potential damage to core components; Lower efficiency and product quality

The role of the laser chiller is to keep the laser marking machine working stably. By precisely controlling the operating temperature of the laser, it ensures that the laser can always maintain its optimal state, avoiding unstable output power or poor beam quality caused by overheating. Especially in high-precision marking, the performance of the chiller directly affects the marking quality.

Laser marking machines can “engrave with light” because a focused laser beam releases high energy in an instant, altering the material surface to create permanent marks.

Different types of lasers are suited for different materials:Fiber lasers excel at metals; CO₂ lasers for non-metals like wood, leather, plastics; UV lasers for ultra-fine, cold processing on sensitive materials.

This versatility makes laser marking widely used across industrial manufacturing, medical devices, and consumer electronics. And to maintain this high efficiency and precision, a reliable laser chiller is indispensable, ensuring long-term stable performance.

Rellene la siguiente información para recibir un presupuesto gratuito y un folleto de productos. Le responderemos en 24 horas.