Quiénes somos

Learn how hydraulic shearing machines work, including cutting principles, key components, and the complete sheet metal cutting process used in industrial fabrication.

Póngase en contacto con nosotros

Entradas recientes

Categorías

Síguenos

Nuevo vídeo semanal

Hydraulic shearing machines are essential equipment in sheet metal fabrication, widely used for cutting steel, stainless steel, aluminum, and other metal sheets with high efficiency and consistent accuracy.

Understanding how hydraulic shearing machines work helps manufacturers, engineers, and buyers make better decisions when selecting equipment and optimizing cutting quality.

This article explains the working principle, main components, and complete cutting process of hydraulic shearing machines, while also clarifying the differences between swing beam and guillotine working mechanisms.

What Is a Hydraulic Shearing Machine?

A cizalla hidráulica is a metal cutting machine that uses hydraulic force to drive a moving blade against a fixed blade, producing a straight and clean cut along sheet metal.

Compared with mechanical shears, hydraulic sheet metal shears provide:

- Higher cutting force

- Better control and stability

- Wider material and thickness range

They are commonly used in industries such as sheet metal fabrication, construction machinery, automotive parts, electrical enclosures, and general metal processing.

Basic Working Principle of a Hydraulic Shearing Machine

The hydraulic shear working principle is based on converting hydraulic pressure into mechanical cutting force.

In simple terms:

- A hydraulic pump generates oil pressure

- Pressurized oil is delivered to hydraulic cylinders

- The cylinders drive the cutting beam downward

- The upper blade moves toward the lower blade to shear the metal sheet

Because hydraulic systems provide stable and controllable force, the cutting motion remains smooth even when processing thicker or higher-strength materials.

Main Components of a Hydraulic Shearing Machine

Understanding the main components helps explain how a hydraulic shearing machine works in real production.

Sistema hidráulico

The hydraulic system is the power source of the machine. It includes:

- Hydraulic pump

- Oil tank

- Control valves

- Hydraulic cylinders

This system controls cutting force, speed, and stability. Proper pressure control is critical for consistent cutting quality and machine safety.

Frame and Cutting Beam

The frame supports the entire machine structure and absorbs cutting forces.

A rigid frame minimizes deformation during cutting, which directly affects accuracy and blade clearance consistency.

The cutting beam connects the hydraulic cylinders and upper blade, transferring force evenly across the cutting length.

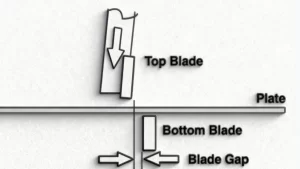

Shearing Blades and Blade Holder

Hydraulic shearing machines use:

- Upper moving blade

- Lower fixed blade

The blade clearance between them is a key factor in cutting quality. Improper clearance can cause burrs, blade wear, or material deformation.

Blade holders ensure precise alignment and secure positioning of the blades during operation.

Backgauge and Material Positioning System

The backgauge positions the sheet metal before cutting and ensures repeatable cutting length.

Accurate backgauge control improves efficiency and reduces material waste, especially in batch production.

Modern hydraulic shears often use CNC-controlled backgauges for higher precision.

Hydraulic Shear Cutting Process: Step by Step

En hydraulic shear cutting process follows a clear and repeatable sequence:

Posicionamiento de las hojas

The operator places the metal sheet on the worktable.Backgauge alignment

The backgauge moves to the preset position, defining the cutting length.Blade clearance setting

Blade gap is adjusted based on material thickness and type.Hydraulic cutting action

Hydraulic cylinders drive the cutting beam downward, and the blades shear the material.Finished edge inspection

The cut edge is checked for straightness, burr level, and surface quality.

This controlled process explains why hydraulic shearing machines are widely preferred for industrial sheet metal cutting.

Swing Beam vs Guillotine: Differences in Working Mechanism

Although both are hydraulic shearing machines, swing beam shears and guillotine shears differ in how the cutting beam moves.

Swing Beam Working Mechanism

A swing beam hydraulic shear uses a pivoting cutting beam.

The upper blade moves along a slight arc during cutting, reducing structural complexity and manufacturing cost.

This mechanism is suitable for thin to medium sheet metal where standard accuracy is sufficient.

Guillotine Working Mechanism

A guillotine hydraulic shear uses a vertically guided cutting beam.

The upper blade moves straight down along linear guides, maintaining consistent blade clearance across the entire cutting length.

This vertical cutting motion improves accuracy and is better suited for thicker plates and precision-oriented applications.

For a full selection comparison, see our guide on swing beam vs guillotine hydraulic shear.

Common Operating Factors That Affect Cutting Quality

Even with a reliable machine, cutting quality depends on several operating factors:

- Blade clearance – Incorrect gap causes burrs or excessive blade wear

- Material thickness and strength – Thicker plates require proper clearance and pressure

- Cutting angle – Affects cutting force and edge finish

- Hydraulic pressure stability – Fluctuations reduce consistency

Among these, blade clearance adjustment plays a particularly important role in maintaining edge quality and blade life.

Conclusión

Hydraulic shearing machines combine hydraulic power, rigid structure, and precise blade control to deliver efficient and reliable sheet metal cutting.

By understanding how hydraulic shearing machines work, manufacturers and buyers can better evaluate machine types, operating parameters, and application suitability.

This technical foundation also helps clarify why different shear designs—such as swing beam and guillotine—perform differently in real production environments.

FAQ: How Hydraulic Shearing Machines Work

How does a hydraulic shearing machine cut metal?

It uses hydraulic pressure to drive a moving blade against a fixed blade, shearing the metal sheet along a straight line.

What is the difference between swing beam and guillotine working principles?

Swing beam shears use a pivoting cutting motion, while guillotine shears use a vertical cutting motion with linear guides.

What affects cutting accuracy in a hydraulic shear?

Frame rigidity, blade clearance, cutting mechanism, and hydraulic system stability all affect accuracy.