Industry 4.0: Smart & Energy-Saving Flexible Bending Centers

- Conocimientos, Noticias

- 90+ reading now

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

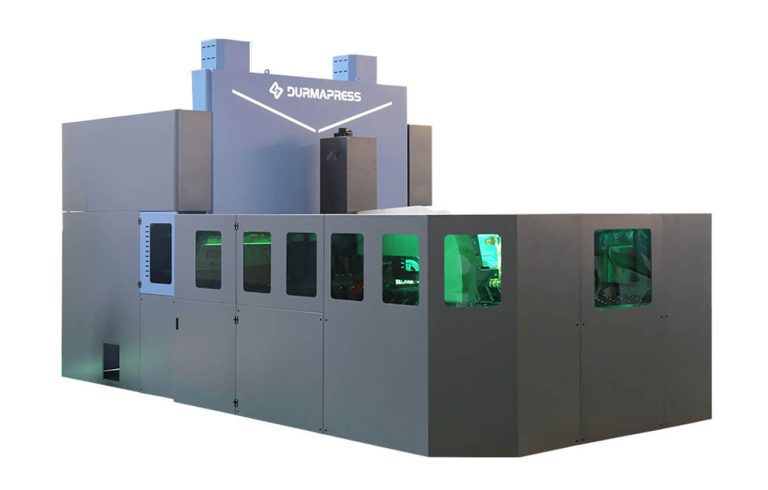

The intelligent flexible bending center is a high-tech product developed to improve production efficiency, reduce labor intensity, lower labor costs, and enhance corporate image in the sheet metal industry. It has been widely applied in various industries such as file cabinets, electrical cabinets, door manufacturing, tool cabinets, kitchenware, ventilation, air conditioning, purification, education, and laboratory equipment.

Twenty years ago, the competitiveness of a bending machine depended on its tonnage output: 300 tons, 500 tons, 1000 tons... The higher the tonnage, the thicker the sheet metal it could process. However, this also meant a larger mold library and longer mold change times. Faced with market demands for "small batches, multiple varieties, and rapid iteration," traditional rigid bending machines began to appear cumbersome and energy-intensive, failing to meet the market's requirements for production efficiency and flexibility.

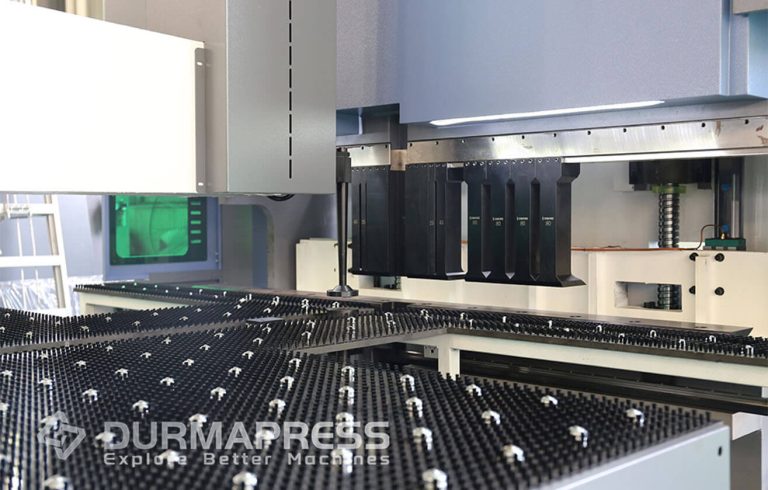

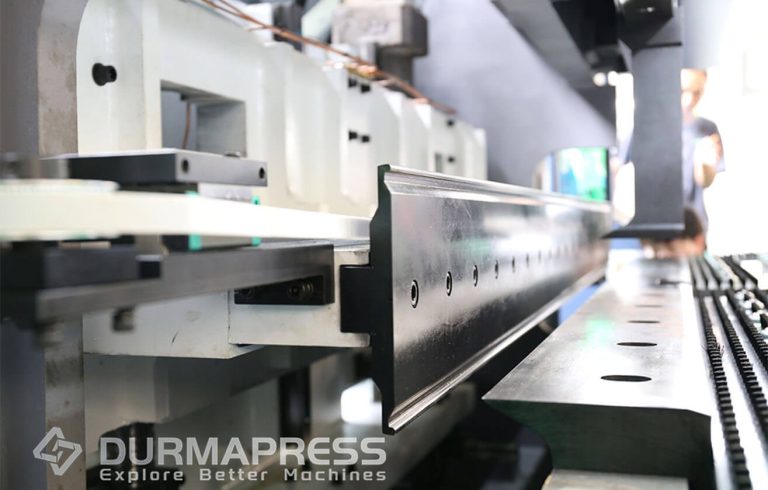

The flexible bending center has integrated the core element of "molds" into the machine itself: a rotatable bending knife, a programmable pressure pad, and a pair of 360° rotatable clamping arms can perform bending actions that previously required 20 sets of molds. This innovation not only greatly simplifies the use of molds but also reduces the mold change process from hours to seconds, significantly increasing production efficiency, reducing production costs, and bringing unprecedented flexibility to sheet metal processing.

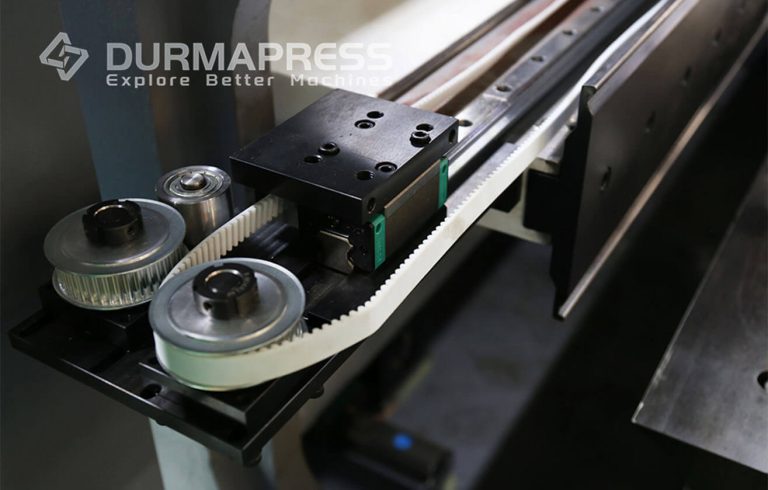

When servo motors, laser rulers, vision cameras, and MES systems are combined with the flexible bending center, the machine acquires "eyes, brain, and neural network." It is no longer a simple bending device but an intelligent production line capable of autonomous thinking, scheduling, detection, and optimization. This high degree of automation not only improves production efficiency but also enhances the stability and consistency of product quality, laying a solid foundation for the intelligent development of the sheet metal industry.

The reasons why intelligent flexible bending centers are gradually replacing traditional bending machines can be explored from multiple dimensions. This transformation is not only a product of technological development but also a result of the combined push of market demand, production efficiency, and cost control.

The main advantages of the intelligent flexible bending center over traditional bending machines are as follows:

The intelligent flexible bending center achieves complete automation in the bending process, with a speed of up to 0.2 seconds per knife, significantly reducing the cycle time for multi-edge and multi-pass bending. This speed is more than three times faster than that of traditional CNC bending machines. The more complex the workpiece and the more edges it has, the greater the speed advantage. Traditional CNC bending machines require skilled workers to hold the workpiece for positioning and bending, with each edge requiring repositioning, resulting in lower efficiency.

The intelligent flexible bending center has low technical requirements for workers. Ordinary workers can be trained to operate it without the need for experienced skilled workers. The fully automated bending process greatly reduces labor costs and worker fatigue. Traditional CNC bending machines often require multiple workers to handle larger workpieces, while the intelligent flexible bending center only requires workers to place the workpiece on the worktable, with the machine automatically completing positioning. It is truly time-saving and labor-saving.

The intelligent flexible bending center eliminates the need for manual holding of workpieces, with the entire bending process being fully automated, significantly reducing the safety hazards caused by worker misoperation.

The intelligent flexible bending center uses graphical visual programming. Workers only need to input bending data based on the workpiece, and the system automatically generates bending instructions without the need for code programming. Ordinary workers can master it in just 2 hours. Traditional CNC bending centers require workers to have complex programming skills and to remember the bending sequence for each edge during the bending process, which is difficult and prone to errors.

The intelligent flexible bending center can achieve automatic positioning of sheet metal with high system positioning accuracy, resulting in higher consistency in the finished products, making it more suitable for mass production. Traditional CNC bending centers have lower positioning accuracy and may have dimensional errors due to multiple positioning processes.

The intelligent flexible bending center is equipped with a rich set of interfaces for easy connection with upstream and downstream production lines. It can be connected to robotic arms to achieve fully automatic loading and unloading. When paired with a self-driven robotic arm and the same control system as the intelligent flexible bending center, the coordination efficiency is higher. When changing workpieces, there is no need to maintain two sets of programs; simply changing the bending center program will automatically generate the robotic arm program, offering greater flexibility.

The reasons why intelligent flexible bending centers are gradually replacing traditional bending machines are multifaceted. They not only have significant technological advantages but also better meet market demands, improve production efficiency, and reduce production costs. This transformation is not only an inevitable result of technological development but also a reflection of changes in market demand and production environment.

In the new era, due to changes in market demand, customer orders have shifted from large batches of single varieties to small batches and multiple varieties. In this situation, the production model of enterprises has also changed accordingly. Smaller batches often mean shorter delivery times, while multiple varieties require enterprises to constantly switch production.

For traditional enterprises, it is often difficult to balance these two factors. Producing multiple products usually means customizing a variety of different molds. During product conversion, workers need to manually change molds, and for products of different sizes, multiple workers may be required to operate. This makes it impossible to ensure delivery times. Moreover, due to the significant investment in mold making and labor costs, profits are greatly reduced. Therefore, the flexibility and high efficiency of equipment have become crucial.

To solve such problems, flexible and highly efficient equipment is needed, which is one of the core capabilities of the bending center. The bending center is equipped with universal universal bending molds and an automatic pressure pad adjustment device (ABA), which can achieve "0" second automatic mold change when bending workpieces of different shapes. Its flexible production mode perfectly solves the problem of product diversification. There is no need to stop the machine during product conversion, and it can adapt to changes with a constant solution. At the same time, in the bending process of complex or complete set products, there is no longer a need to change molds or adjust equipment halfway. With the support of the flexible bending center, mold and labor costs are greatly saved, mold change and setup times are reduced, and a single machine can handle small batch and multiple variety orders.

The Durmapress flexible bending center uses a four-sided bending knife and universal pressure pad, which can complete mold change in 30 seconds. This innovation not only greatly improves production efficiency but also reduces mold costs and mold change time, enabling enterprises to more flexibly respond to market changes and customer demands.

This series of flexible bending centers has a repeat positioning accuracy of 0.01 mm, with a first-piece pass rate as high as 99.8%. This high-precision positioning and processing capability ensures the consistency and stability of product quality, meeting the strict quality requirements of high-end manufacturing and enhancing the market competitiveness of products.

The Durmapress flexible bending center adopts full-servo energy-saving technology, which can save up to 20,000 kWh of electricity per year and reduce carbon emissions by 45%. This technology not only reduces production costs for enterprises but also reduces environmental impact, reflecting corporate social responsibility and meeting the modern society's requirements for green manufacturing.

In the future, as the manufacturing industry continues to develop and technology keeps advancing, the application scope of intelligent flexible bending centers will further expand, and their position in the manufacturing industry will become more solid. At the same time, this will also drive the entire manufacturing industry towards a more efficient, intelligent, and green direction.

Rellene la siguiente información para recibir un presupuesto gratuito y un folleto de productos. Le responderemos en 24 horas.