Shipment Case Report – Durmapress Hydraulic Press Brakes Delivered to Ukraine

- Envío

- 100+ reading now

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Durmapress has successfully completed another international delivery, this time shipping a total of three hydraulic press brakes to a long-term manufacturing client in Ukraine.

The shipment includes a combined setup of:

DP-ES Series Hydraulic Press Brake – 110T3200

DP-ES Pro Max Series Hydraulic Press Brake – 135T3200 (×2 units)

The client operates in metal fabrication for infrastructure and industrial machinery, requiring stable bending performance, higher accuracy, and reduced downtime.

This delivery forms part of their equipment expansion plan for 2025, aimed at increasing throughput while maintaining consistent bending quality across medium-to-large steel components.

The machines—representing the newest generation of brakes hydraulic press solutions—were prepared under enhanced export specifications to accommodate Ukraine’s operating environment and production standards.

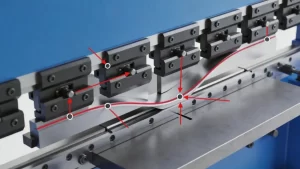

The DP-ES 110T represents the standard configuration of Durmapress hydraulic press brake technology—engineered for general-purpose bending tasks.

Although the exact technical specifications vary by customer, the machine is recognized for:

This model provides the client with a dependable workhorse capable of maintaining consistent bending accuracy throughout continuous production cycles.

The two DP-ES Pro Max models form the core of the customer's upgraded bending line.

As a Pro-level hydraulic press brake, this series is built for higher precision, quicker response, and greater process repeatability, featuring:

With two identical units operating in parallel, the customer gains the flexibility to split production tasks, reduce bottlenecks, and respond faster to varying material thicknesses and bending geometries.

Together, the three machines deliver a balanced system—combining efficiency, power, and process stability—reinforcing Durmapress as a trusted supplier of hydraulic press brakes for global fabrication industries.

Every shipment to Eastern Europe undergoes a full export-grade protection protocol.

For this Ukraine delivery, Durmapress implemented a multilayer logistic process including:

Each press brake was secured onto reinforced wooden and steel-base pallets using:

High-tension steel cables

Industrial-grade anchor points

Anti-shift blocking reinforcement

This prevents movement throughout rail and sea transitions.

Sensitive areas—including hydraulic components, CNC modules, and electrical cabinets—received:

Thick vibration-absorption padding

Multi-layer moisture-proof wrapping

Corrosion-resistant surface shielding

This ensures that the hydraulic press brake systems remain stable despite long-distance transport.

Exposed areas and painted surfaces were covered with:

Abrasion-resistant protective film

Corner guards

Export-grade outer wrapping

Each machine was then crated to meet international shipping standards.

“For every international shipment—especially one involving multiple hydraulic press brakes—we conduct a three-stage inspection to ensure zero risk during transit.

From fastening quality to moisture protection, every step is double-checked.

Our goal is simple: the equipment must arrive exactly as it left our factory.”

— Mark Liu, Senior Logistics Manager, Durmapress

This statement reflects Durmapress’s commitment to safeguarding both the equipment and the trust placed by every overseas partner.

Durmapress continues to expand its global delivery capacity, supporting clients across Europe, the Middle East, Asia-Pacific, and the Americas.

The successful dispatch of these three machines to Ukraine highlights our ability to:

Customize hydraulic press brake configurations for different industries

Provide reliable cross-border packaging and logistics

Support clients with installation guidance and after-sales assistance

Maintain continuous equipment availability for international orders

Whether for standalone units or multi-equipment production lines, Durmapress remains dedicated to delivering reliable technology and long-term support to metalworking companies worldwide.

Rellene la siguiente información para recibir un presupuesto gratuito y un folleto de productos. Le responderemos en 24 horas.