Swing Beam vs Guillotine Hydraulic Shear: Which One Should You Choose?

- Conocimientos, Noticias

- 90+ reading now

Compare swing beam and guillotine hydraulic shears in terms of cutting accuracy, structure, cost, and applications. Learn which hydraulic shear is best for your sheet metal fabrication needs.

Selecting the right hydraulic shearing machine is a key decision for any sheet metal fabrication operation. Among the most commonly compared options, swing beam hydraulic shears and guillotine hydraulic shears stand out due to their distinct structures, cutting behaviors, and application ranges.

Although both machines are designed for efficient metal cutting, their performance differs significantly depending on material thickness, accuracy requirements, and production environment. This article provides a structured comparison to help you clearly understand the differences and make the right purchasing decision.

Hydraulic shearing machines are widely used for straight-line cutting of sheet metal such as carbon steel, stainless steel, and aluminum. By applying controlled hydraulic force to the cutting blade, these machines deliver clean cuts with high efficiency and minimal deformation.

The choice between different shear types is not only about cutting capacity, but also about long-term accuracy, operating cost, and production consistency.

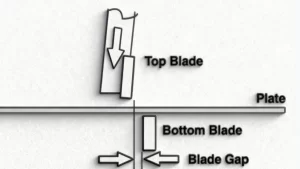

A swing beam hydraulic shear uses a pivoting upper blade mounted on a swinging arm. During the cutting process, the blade moves along a slight arc rather than a straight vertical path. This design allows the machine to maintain a relatively simple structure while delivering reliable cutting performance.

The cutting angle is typically fixed, and blade clearance is adjusted mechanically according to material thickness.

Swing beam shearing machines are valued for their practicality and cost efficiency. Key advantages include:

These characteristics make swing beam shears a popular choice for workshops focused on versatility rather than ultra-high precision.

Despite their advantages, swing beam hydraulic shears have limitations:

Understanding these trade-offs is essential when evaluating long-term production needs.

A guillotine hydraulic shear features a vertically guided ram system, allowing the upper blade to move straight down along linear guides. This vertical cutting motion ensures consistent blade clearance across the entire cutting length.

The rigid frame structure significantly enhances cutting stability, especially when processing thicker materials.

Guillotine hydraulic shears are designed for precision and durability. Their main advantages include:

These features make guillotine shears ideal for industrial-scale production and precision-oriented applications.

The main considerations when choosing a guillotine shear include:

However, for demanding production environments, these factors are often justified by performance benefits.

| Comparison Item | Swing Beam Hydraulic Shear | Guillotine Hydraulic Shear |

|---|---|---|

| Cutting Motion | Swinging arc movement | Vertical linear movement |

| Cutting Accuracy | Medium | High |

| Frame Rigidity | Standard | High rigidity |

| Blade Clearance | Manual / Mechanical | CNC-controlled |

| Suitable Thickness | Thin to medium sheets | Medium to thick plates |

| Edge Quality | Good for general use | Excellent and consistent |

| Automation Level | Basic CNC backgauge | Full CNC integration |

| Maintenance Cost | Lower | Higher |

| Initial Investment | More economical | Higher |

While the comparison table highlights the key differences, the practical impact of these factors is often best understood in real production scenarios.

The higher cutting accuracy of guillotine hydraulic shears mainly comes from their vertical cutting motion and rigid frame structure, which helps maintain consistent blade clearance when processing thicker materials.

Swing beam shears, on the other hand, rely on a pivoting cutting mechanism. This design reduces machine complexity and cost, making them a practical choice for workshops focused on thin to medium sheet metal where ultra-tight tolerances are not critical.

The differences in cutting accuracy and stability largely come from the hydraulic shear working principle and the way the cutting beam moves during operation.

Choose a swing beam hydraulic shear if:

Choose a guillotine hydraulic shear if:

A well-informed selection improves productivity and reduces long-term operational costs.

A common misconception is that guillotine shears are always the better option. In reality, swing beam shears remain highly effective for many applications. Another misunderstanding is assuming blade quality alone determines accuracy, while machine rigidity and clearance control are equally important.

Both swing beam and guillotine hydraulic shears offer distinct advantages in sheet metal fabrication. The best choice depends on material thickness, accuracy requirements, and production scale.

At Durmapress, we manufacture both swing beam and guillotine hydraulic shearing machines, allowing us to provide application-driven recommendations tailored to real production needs.

Is a guillotine hydraulic shear more accurate than a swing beam shear?

Yes, due to its vertical cutting structure and rigid frame.

Which hydraulic shear is better for thick plate cutting?

Guillotine hydraulic shears are better suited for thick materials.

Are swing beam shears suitable for industrial production?

They are suitable for light to medium industrial applications.

Which machine has lower maintenance costs?

Swing beam hydraulic shears generally have lower maintenance costs.

Rellene la siguiente información para recibir un presupuesto gratuito y un folleto de productos. Le responderemos en 24 horas.