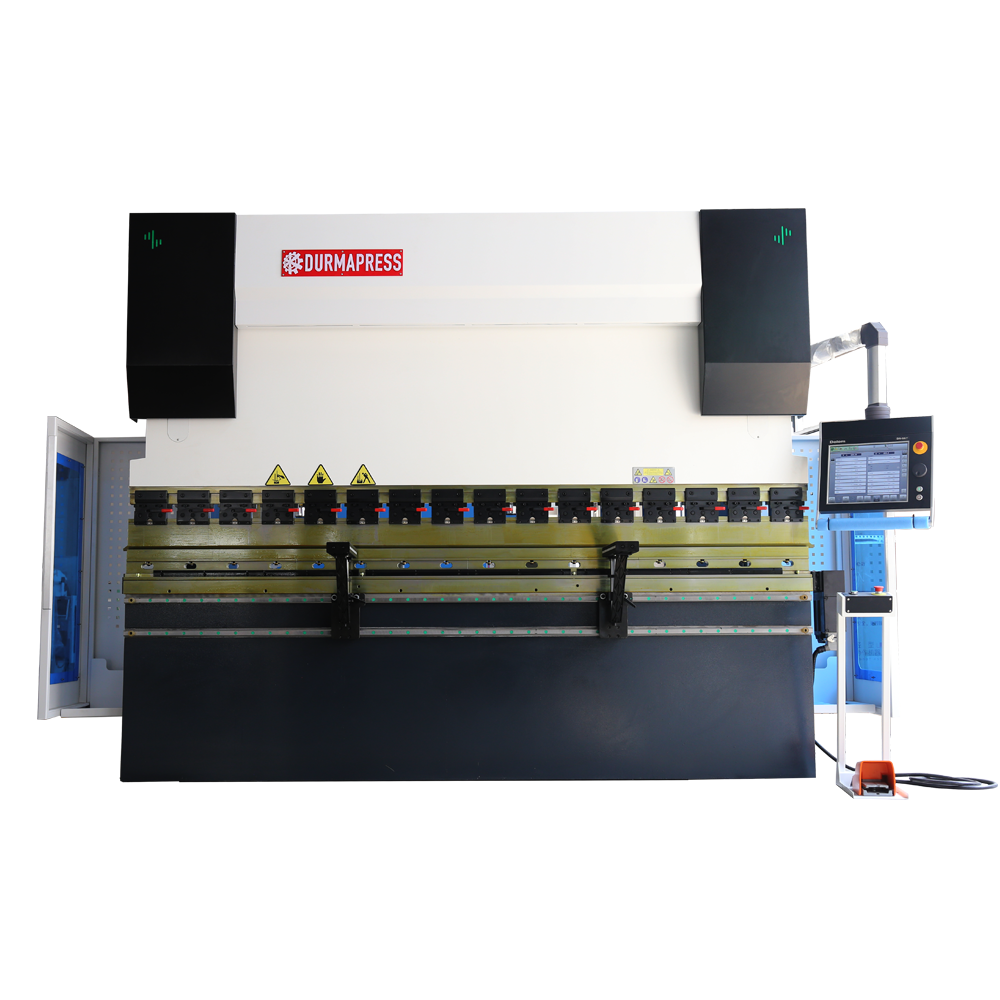

Press Brake Manufacturing

Factory Direct OEM/ODM 5 Years Warranty

As an expert manufacturer, Durmapress ® offering high quality Press Brake solutions to enhance your yield.

Larger Capacity, Better Price.

Annual production up to 50,000 Sets wholesale price.

OEM,ODM Provided

We provide OEM/ODM Service According to Customer Request, Make OEM for more than 30 agents

Certified Products, Safety Guaranteed.

Compliance of ISO and CE, strictly production to guarantee quality.

Revolutionary Products

Our Services & Features

Large Quantity in stock

Large Square Factory with More than 200 workers with 20 years experience of the machine production

Semi-Finished Machine just testing and paint for OEM , Components all in stock to realized the Fast Shipping

Euro-Brand Components To Keep the machine working stability , Passed CE &ISO Certificate , Large quantity production keep the most competitive price .

CNC Controller For Optional

Delem DA-69T

DA-Touch 3D modular press brake control

- 3D and 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- 17" high resolution colour TFT

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control's multitasking environment

- Sensor bending & correction interface

- Profile-T3D offline software

Delem DA-66T

DA-Touch 2D modular press brake control

- 2D graphical touch screen programming mode

- 17" high resolution colour TFT

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control's multitasking environment

- Sensor bending & correction interface Profile-TL offline software

Delem DA-58T

DA-50Touch 2D graphical press brake control

- 2D graphical touch screen programming

- 15" high resolution colour TFT

- Bend sequence calculation

- Crowning control

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- USB, peripheral interfacing

- Profile-T offline software

Delem DA-53T

DA-50Touch numerical press brake control

- "Hot-key” touch navigation

- 10.1" high resolution colour TFT

- Up to 4 axes (Y1,Y2 + 2 aux. axes)

- Crowning control

- Tool / material / product library

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- TandemLink (option)

- USB memory stick interfacing

- Profile-T offline software

CybTouch 8 PS

CybTouch 8 PS is specifically developed for synchronized press-brakes.

- Intuitive user-friendly interface.

- Simple pages, clear display, large keys.

- Large, vivid and high-contrast fully touchscreen.

- Complete programming for efficient mass-production with multiple bends.

- Easy single bends with EasyBend page.

- On-line help and interactive warning pop-ups.

- Comfortable wireless data backup and software updating using PC or Notebook.

- Large variety of languages available.

CybTouch 12 PS

CybTouch 12 PS is specifically developed for synchronized press-brakes

- Large, vivid and high-contrast fully touchscreen.

- Simple pages, clear display, large keys.

- Intuitive user-friendly interface.

- Complete programming for efficient mass-production with multiple bends.

- Easy single bends with EasyBend page.

- On-line help and interactive warning pop-ups.

- Comfortable wireless data backup and software updating using PC or Notebook.

- Large variety of languages available.

CybTouch 15 PS

The CybTouch 15 PS is a 2D numerical control

- 15” modern streamlined glass surface touch screen that can be used with gloves.

- User friendly HMI thanks to intuitive programming and easy to setup with dedicated wizards (autotuning).

- 2D graphical profile drawing (Touch Profile) and precise 2D program creation.

- Automatic bending sequence calculation.

- Easy single bends thanks to the EasyBend page.

- Wide storage capacity.

- Internal backup and restore functions.

- Wireless communication for extended diagnostics and updates (with laptop).

VisiTouch 19

The VisiTouch 19 is a 2D graphical numerical control

- 19” modern streamlined glass surface touch screen that can be used with gloves.

- User friendly HMI, similar to the CybTouch’s one, thanks to an intuitive programming and dedicated set-up wizards (auto-tuning).

- 2D graphical profile drawing (Touch Profile) and precise 2D program creation.

- 3D visualization of imported parts.

- Angle measurement with various angle protractors

- Running under Windows 10 for multi-tasking and networking.

- Automatic bending sequence calculation.

- Internal backup and restore functions.

- Outstanding diagnostic tools.

The Processing Steps Of the Machine

Overall Welding Fabrication

Noted: Machine frame Adopt Overall Fabricating By Floor-type

Boring & Milling Machine

Overall welding fabricating of workbench vertical plate and

machine body ensures the platness of the workbench.

Precise boring bore

Overall fabricating of fixed seat and fixed hole ensures the two

oil cylinder in the same level namely, with same Y axis axis

value when working, to protect the oil cylinder and machine.

Finite Anyalysis

Workbench adopts finite-element analysis curve fabricating,

avoiding uneven pressure, and reducing the cutting linearity

deviation. .

Heat Treatment by Tempering Furnace

Machine frame and slider hardened by heat treatment to

guarentee the frame strength, lengthen the service life, and

improve the bending accuracy.

Our Processing Equipment

Our processing equipment including the heavy duty shot

blasting machine.5-axis machining center, large grinding

machine, floor type boring & milling machine, large annealing

temper furnace. CNC machining center ect.

Get A Free Quote

Contact us to get a free quote and more expertise about custom aluminum extrusion. Your project will meet a right solution with Durmapress.

Custom Sheet Metal Machinery with Easy

At Durmapress, We turn complex Into Simple! Follow the following 3 steps to start today!

1

Tell Us What You Need

Tell us Press Brake ,Do you Prefer CNC or NC Controller ?

2

Get Solution & Quote

Material ?

Max.Thickness ?

Length ?

Above three details , then we suggest machine model

3

How many Axis Do you need ?

3+1 , 4+1 , 6+1 , 8+1 Axis