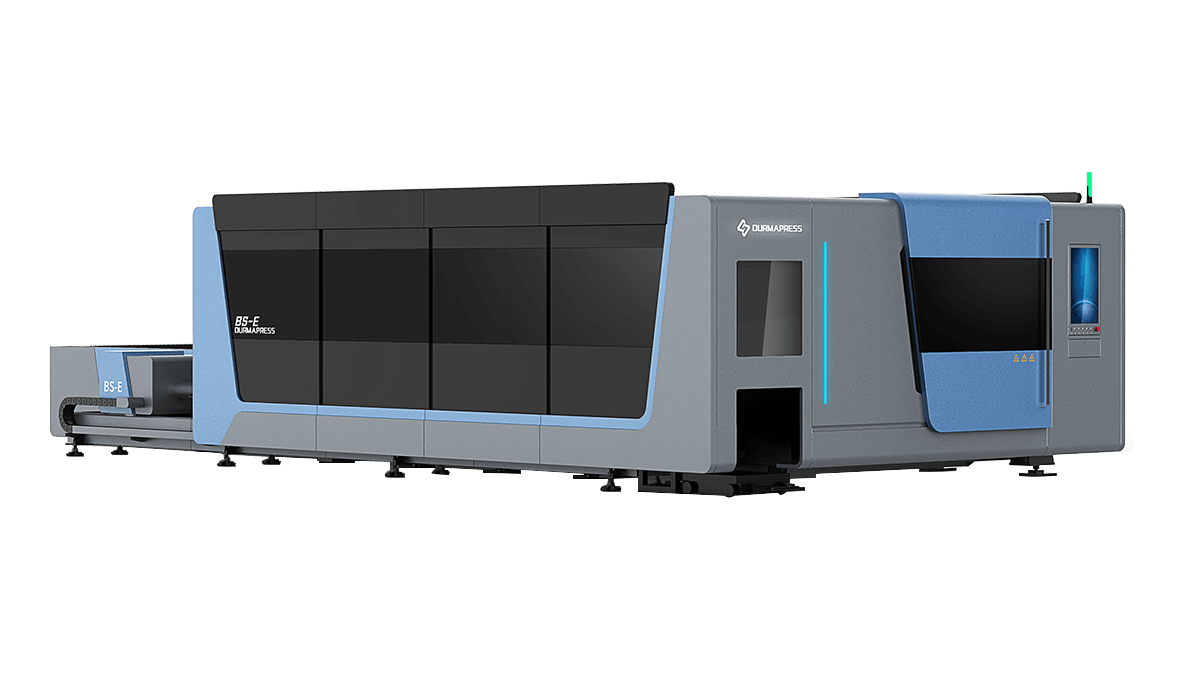

SERIE BS-E

MÁQUINA DE CORTE POR LÁSER DE FIBRA

Alta eficiencia y ahorro de energía, capaz de fabricar piezas complejas.

Trusted by 5000+ manufacturers worldwide

Product Overview

Engineered for precision, efficiency, and reliability in modern manufacturing environments

Revolutionary cutting Technology

Our High-Precision Fiber Laser Cutting Machine represents the latest in industrial cutting technology, designed for metal fabrication and machinery manufacturing.

Advanced Technical Features

- Sheet & Tube in One – One machine for both sheet and tube cutting

- Full Enclosure Safety – CE-compliant, clean and safe operation

- High Rigidity Structure – Stable, precise, and reliable cutting

- Fast Mode Switching – Reduced downtime, higher efficiency

- Space & Cost Saving – Lower investment and operating costs

- Exchange Worktable – Enables continuous loading and unloading during cutting, reducing downtime and improving productivity.

Detailed Design & Components

Explore the precision engineering behind our BS-E series fiber laser cutting systems

Laser Chuck

Since the cylinder is uesd to clamp the workpiece directly,the cylinder working stroke is the chunk working stroke,and the clamping range is wide. With direct cylinder output, the output force is linearly proportional to the air presssure,which is easy to implement software control.

Laser Cutting Head

Lightweight and impact-resistant, designed for medium- and low-power lasers. Built-in intelligent sensors enable real-time monitoring, rapid diagnostics, and stable, efficient cutting.

Control Panel

High-end intelligent EtherCAT bus controller designed for high power fiber laser above 8kw.featured by out of box service, easy to install and adjust, full solution

functions,supports custom, automatic and digitization solutions.

Chiller

It is a device that provides cooling for the resonator and the optics in the cutting head. lt features a water-based coolingsystem.Thanks to the dual-chamber system, cooling water at different temperatures is delivered to the optics and the laser power supply according to their needs.

Exchange worktable

The exchange worktable allows simultaneous cutting and material loading/unloading, minimizing downtime and increasing productivity. With fast and stable table switching, it ensures efficient, safe, and continuous operation for high-volume cutting tasks.

Fully Annealed Semi-hollow Frame

Durmapress steel frames are annealed at over 600° to relieve internal stress.This ensures they can withstand heavy use without distortion.

The advanced semi-hollow bed design dissipates more heat than competitors and prevents deformation.

Sistema de vacío y filtrado de 6 celdas

The vacuum and filter system improves cutting quality, protects health, and keeps the machine clean. The cutting area is divided into vacuum cells that open and close automatically with the movement of the cutting head, ensuring efficient and continuous suction.

Cypnest Software

CypNest is a nesting software for CypCut/HypCut laser cutting systems, integrating drawing editing, fast nesting, toolpath generation, and production analysis to improve cutting efficiency and meet diverse production needs.

Cabezal de corte

Customize The Cutting Head For Your BS-E Series

Bevel Head+45°(Option)

Bevel Head for vertical and bevel cuts from 0° to 45°.Optimal resuits provided through the combination of 5 axis interpolation and software . Positive and negative bevel anglesin one part

PRECITEC (Option)

Laser cutting head in solid state, high power Precitec PROCUTTER, with capacitive sensor for tracking metallic surfaces and support for focal lens 200mm, with cartridge glass protection

Fuente láser

Customize The Laser Source For Your BS-E Series

- Supports faster cutting speeds and efficient processing of thick and hard materials.

- Delivers consistent output with reduced downtime and maintenance needs.

- Suitable for metals, plastics, ceramics, and composite materials across various industries.

- Ensures accurate cutting with fine details and tight tolerances.

Automatic Loading & Unloading System

The system integrates robotic loading/unloading arms with a sheet metal warehouse and laser cutting machine to achieve fully automated sheet storage and handling, improving efficiency and reducing costs.

High-load vacuum suction cups with zoning control and imported pumps ensure stable performance. Sheet-shaking and thickness-detection mechanisms automatically separate adhered sheets, and if separation fails twice, the system alarms for manual intervention.

Coil Fed Blanking & Laser Cutting Line

Coil Fed Blanking & Laser Cutting Line is an advanced manufacturing process that combines the efficiency of coil-fed material handling with the precision of laser cutting.

Instead of using pre-cut sheets, this coil fed laser system feeds metal directly from a coil, flattens it, and cuts it into custom shapes — all in a continuous, automated line.

Laser Isse coil-fed laser blanking lines feature enhanced efficiency, precision, cost-effectiveness, versatility, and sustainability compared to traditional methods.

Especificaciones técnicas

Engineered to deliver exceptional performance across a range of manufacturing requirements

For complete technical specifications and custom configuration options

Why Choose us

Eficacia

Reliability

Support

Ver el vídeo

Fabricante de equipos punteros de tratamiento de metales

Aplicaciones

They are versatile and can be used across a wide range of materials

Home appliances

Shipbuilding

Kitchenware

Metalworking

Medical equipment

Auto manufacturing

Ready to Transform Your metal Process?

Get a personalized quote for your specific needs and discover how the bending machine can enhance your production efficiency and product quality.

- Free consultation with our experts

- Customized solution based on your requirements

- Competitive pricing with flexible financing options

- Comprehensive training and ongoing support

- 5-Year Warranty