In the field of metal processing, bevel cutting is an indispensable process before welding. Traditional cutting methods such as flame cutting, plasma cutting or mechanical milling have long been the mainstream. However, as the manufacturing industry has increasingly stringent requirements for efficiency, precision and cost, laser bevel cutting technology has gradually become the focus of the industry. This article will combine technical comparison with user practice to analyze the core advantages of DURMAPRESS laser bevel cutting.

Technical bottlenecks of traditional thermal cutting process

In the metal sheet processing industry, processing ultra-thick and highly reflective metal sheets has always been restricted by technology. Taking stainless steel, carbon steel, aluminum alloy and other materials as examples, when using plasma or flame cutting processes, multiple problems restrict production quality and efficiency.

From the perspective of cutting surface quality, the surface roughness of the cutting surface of the traditional process fluctuates significantly, making it difficult to meet the needs of high-precision welding. During the cutting process, the large amount of heat input leads to the expansion of the heat-affected zone and changes in the material structure and properties, which in turn affects subsequent processing. In terms of the balance between cutting speed and precision, traditional methods often lose one thing while focusing on the other: when pursuing speed, the cutting accuracy decreases and the groove angle deviation is large; when focusing on precision, the cutting efficiency drops sharply and cannot meet the needs of large-scale production. In addition, for ultra-thick plates, the cutting capacity of traditional processes is limited. When facing plates with a thickness of more than 20mm, the cutting stability and quality control difficulty increase exponentially, becoming a technical barrier that the industry has long been difficult to break through.

Core breakthrough in laser cutting technology

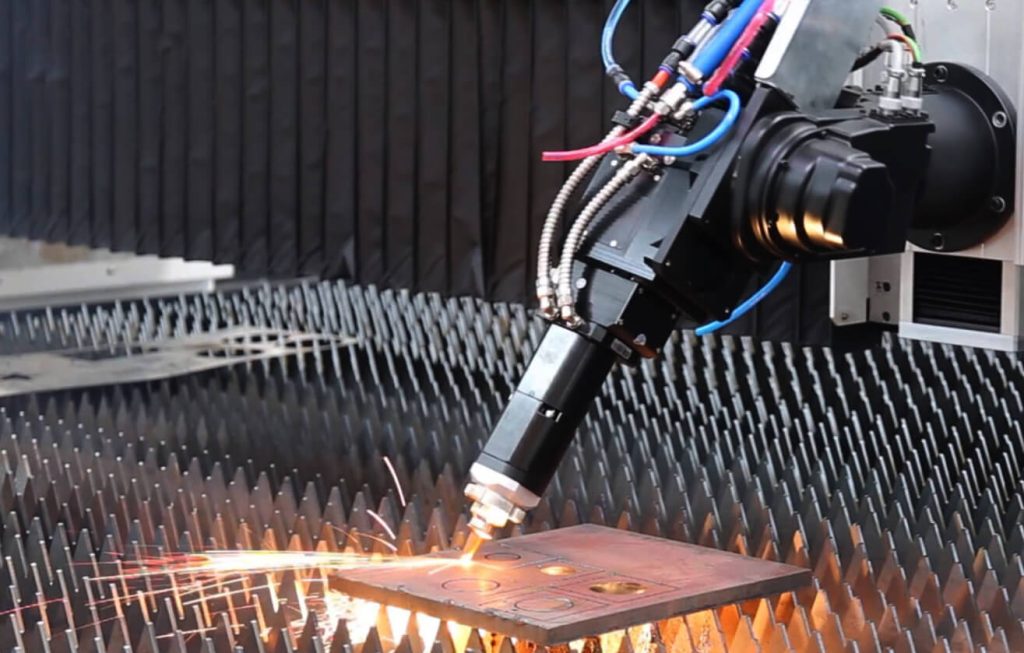

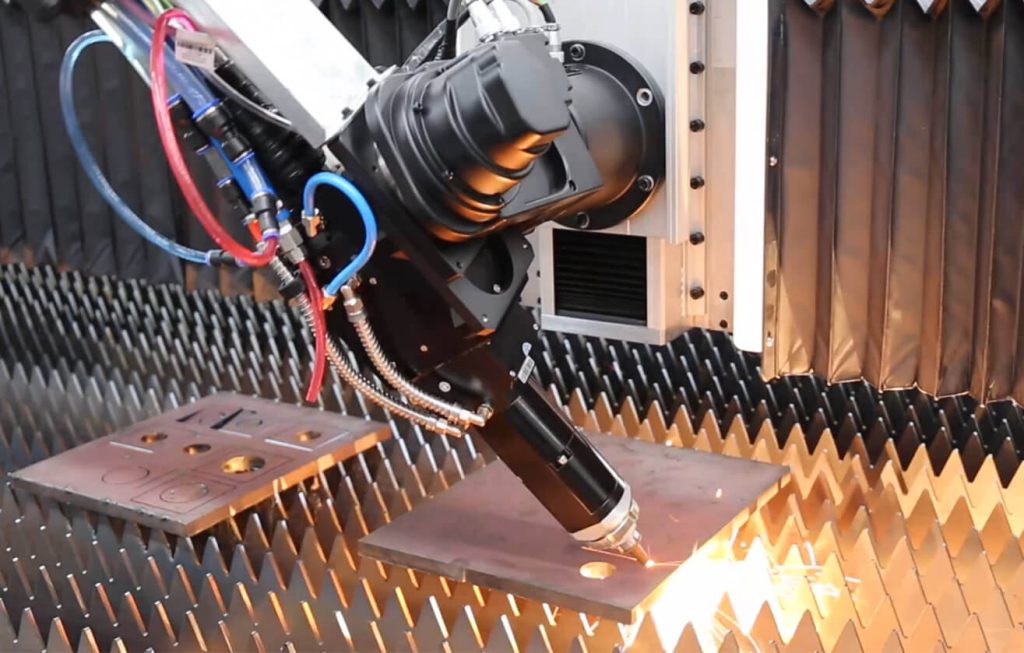

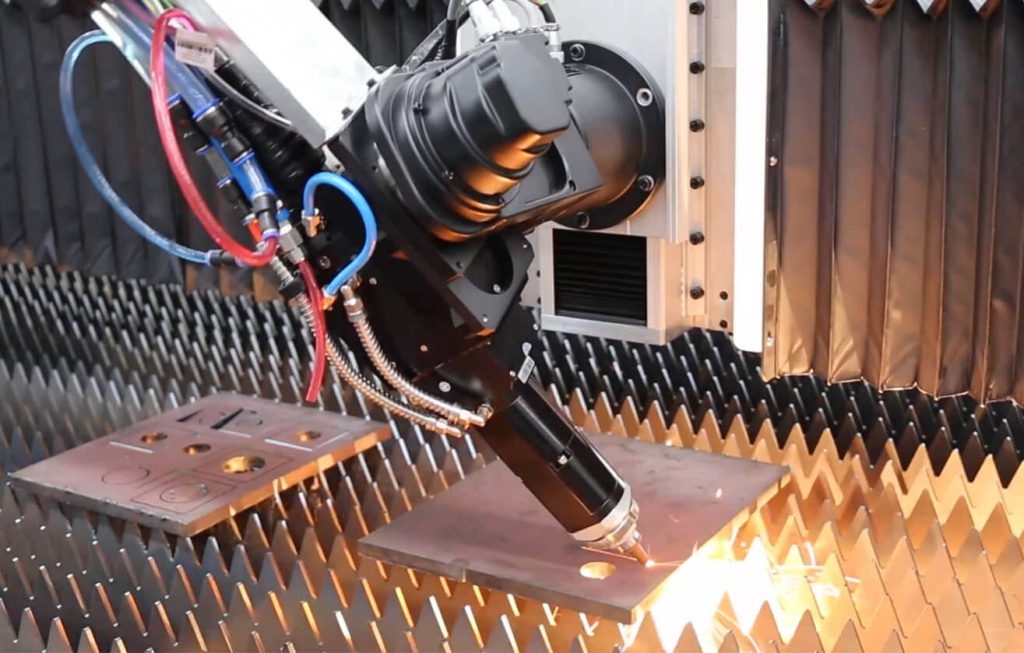

In the field of laser cutting, when traditional processes are used to process materials such as stainless steel, carbon steel and aluminum alloy, the traditional thermal cutting technology leads to technical problems such as unstable cutting quality, difficulty in balancing precision and efficiency, difficulty in processing ultra-thick plates, complex procedures and high costs. DURMAPRESS has successfully resolved these problems by optimizing the laser cutting machine and matching it with a high-power laser. During the cutting process, the optimized laser can act accurately on the surface of the material, just like a skilled craftsman, meticulously carving every detail. The high-power laser cutting machine of DURMAPRESS is shown in the figure below.

In terms of cutting edge processing, DURMAPRESS has broken through the limitations of traditional processes. The advanced beam control technology is like giving the laser a pair of flexible "hands", allowing it to shape the cutting edge as it pleases. Whether it is a complex shape or a tiny component, it can be easily handled. This fine shaping greatly improves the cutting accuracy and makes the cutting edge smoother. This not only provides an ideal docking surface for subsequent welding work, making the welding more solid, but also reduces many troubles for assembly work, greatly improving the overall efficiency and quality of production.

Multiple advantages of bevel cutting

1.Full coverage of groove types, simplified process and improved efficiency

In the field of bevel cutting, traditional processing methods often face many challenges. For example, when processing complex bevels such as V-shaped, Y-shaped, and X-shaped, multiple devices need to work together, and multiple processes such as milling and grinding are required. In this process, frequent clamping and positioning are not only time-consuming and labor-intensive, but also easily lead to the accumulation of errors between processes, which ultimately affects the consistency of the bevel size.

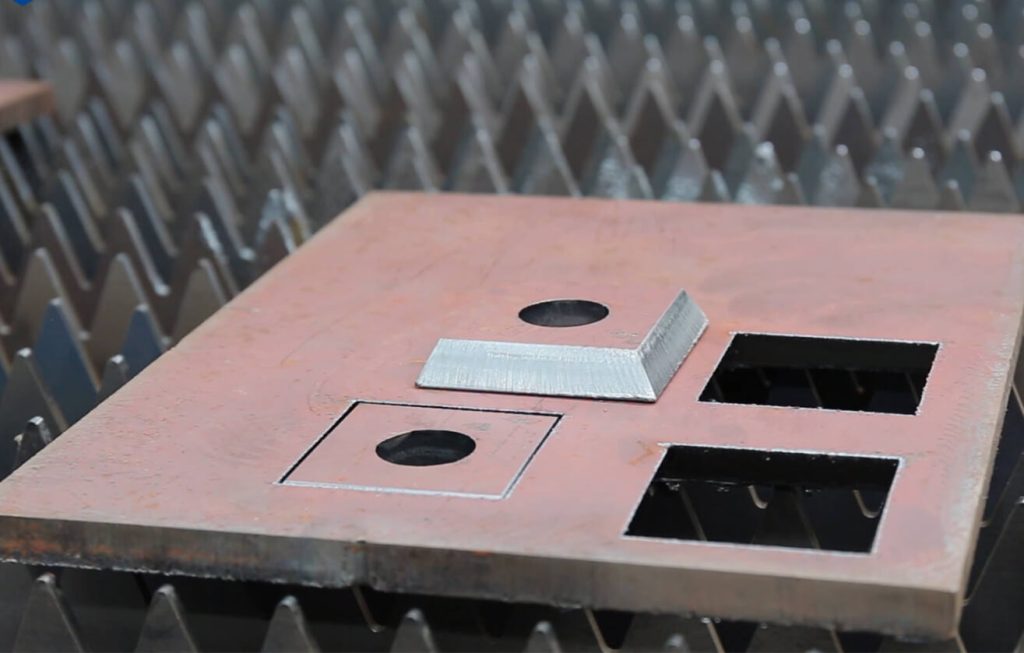

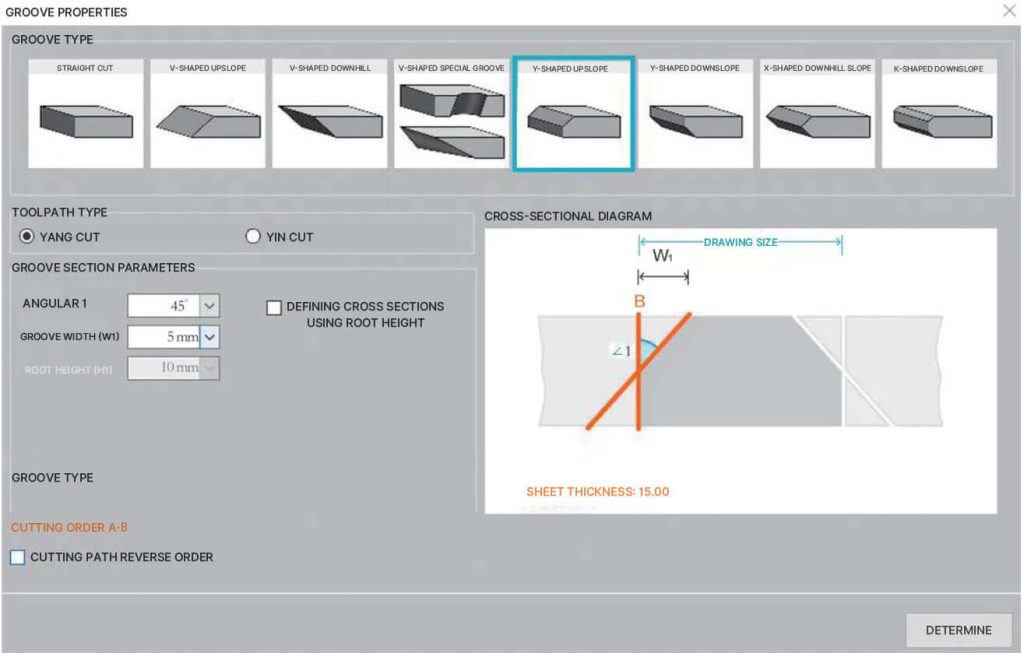

Today's laser cutting technology has brought a new solution, which can complete complex bevel shapes with just one processing. The bevel laser cutting machine can set a variety of cutting angles, such as 0°~45° bevel cutting and V-shaped, Y-shaped, X-shaped, K-shaped, gradient bevel cutting can be easily handled, as shown in the figure, which can save production processes and reduce welding difficulty. During the processing, there is no need for repeated clamping, which greatly simplifies the production process and effectively avoids errors caused by multiple clamping, thereby ensuring a high consistency of the bevel size. This efficient and precise cutting method not only improves production efficiency, but also better adapts to diverse production needs. Whether it is large-scale mass production or small-batch customized processing, it can show strong advantages.

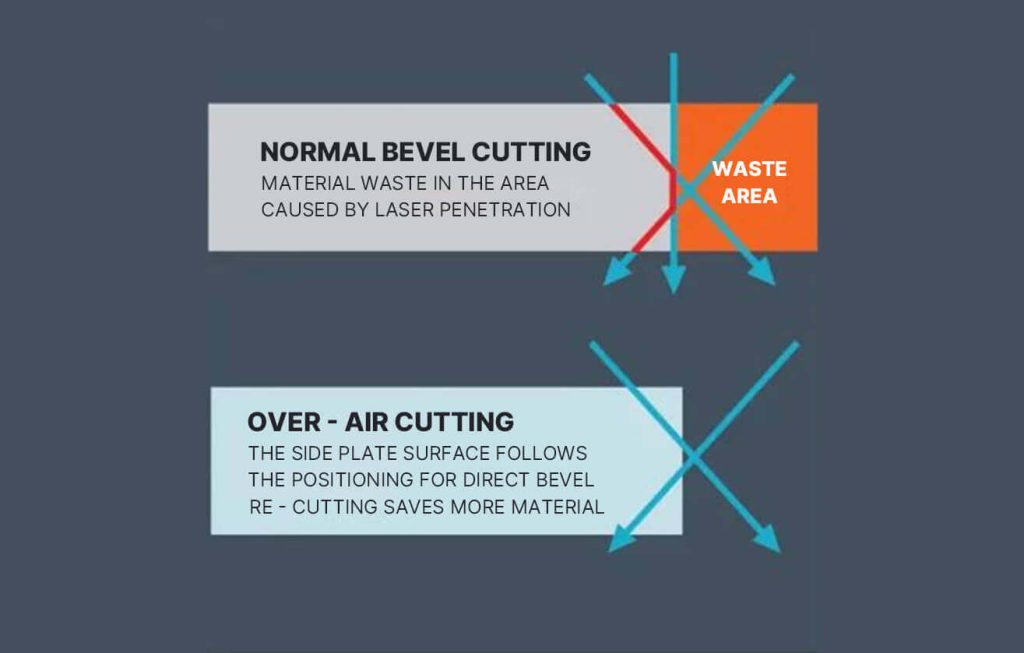

Extreme material saving, mid-air cutting

K-shaped groove cutting in sheet metal processing is extremely important for material saving. Traditional cutting methods are wasteful and significantly increase costs. Advanced cutting technology accurately plans the path, uses intelligent algorithms and optimized processes to rationally utilize sheets and minimize waste. It not only reduces raw material costs, but also reduces waste processing, improves resource utilization, helps companies balance processing quality, and achieves a win-win situation for economic and environmental benefits. The schematic diagram of aerial cutting is shown in the figure.

Improved welding accuracy and quality, a more solid foundation

By precisely controlling the energy distribution of the laser beam and the cutting angle, the cutting accuracy is greatly improved. The groove angle error is controlled within a very small range, the cutting surface roughness is low, and the incision is smooth and stable. This high-quality groove cutting lays a solid foundation for the welding process: the weld fusion is more uniform, and welding defects such as pores and slag inclusions are reduced, and the weld strength and overall structural reliability are improved. It is especially suitable for engineering machinery, shipbuilding and other fields with extremely high requirements for welding quality.

Application Areas

The main application areas of laser bevel cutting technology are shown in the figure below. It is not only suitable for high-end fields with strict requirements on welding quality, but also can meet diversified needs such as large-scale industrial production and precision micro-machining. Its intelligent and flexible characteristics make it a core tool for manufacturing industry upgrades, helping enterprises achieve "high precision + low cost + fast response" competitiveness upgrades.

Conclusão

The bevel cutting technology of laser cutting machines is reshaping the value chain of the metal processing industry with its high-precision, high-efficiency and high-flexibility technical characteristics. It not only brings about the upgrade of processing technology, but also promotes the optimization of the entire process from design to production. For modern enterprises that pursue quality and efficiency, laser bevel cutting is not only a technical choice, but also a strategic investment to achieve the transformation of intelligent manufacturing.

In addition, the continuous improvement of the automation and intelligence level of the bevel cutting technology of laser cutting machines has further enhanced its competitiveness in the field of metal processing. The automated cutting system can operate 24 hours a day, reduce manual intervention and improve production efficiency. At the same time, the intelligent monitoring system monitors the cutting process in real time, and adjusts immediately once an abnormality is found to ensure stable and reliable cutting quality. This highly intelligent production method not only reduces labor costs, but also improves production safety, injecting new impetus into the sustainable development of the metal processing industry.

Sobre nós

A Durmapress é especializada na conceção, fabrico e venda de vários equipamentos de processamento de metal, incluindo máquinas de dobragem, tesouras, punções, máquinas de corte a laser, etc. A empresa foi fundada em 2000. Com anos de experiência e acumulação de tecnologia. DurmaPress tornou-se uma das marcas bem conhecidas na indústria de máquinas de processamento de metal da China.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.