Choosing The Right Press Brake Tooling: Your Most Critical Production Decision

- Conhecimento, Notícias

- 100+ reading now

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Selecting the best press brake tooling is crucial for both accuracy and efficiency. This guide redefines what “best” truly means—beyond brands—by explaining tooling types and systems, and introducing a five-step decision-making framework to match materials and machines. With the right choice and maintenance, tooling can evolve from a consumable item into a valuable asset that enhances manufacturing performance.

Choosing the “best” tooling does not mean buying the most famous brand or the most expensive option—it means building a framework of excellence driven by actual application requirements. “Best” is a relative and dynamic concept, determined by the optimal match between material characteristics, process demands, and machine parameters.

For press operations involving hard materials, the tooling must exhibit outstanding wear resistance and deformation strength to maintain its shape and precision under long-term high pressure. Key performance indicators include hardness, wear resistance, and compressive strength. Recommended materials: Cr12MoV, SKD11 high-hardness alloy steels.

When processing tough materials, tooling must provide superior impact resistance to prevent cracking or chipping caused by repeated impact. Key indicators: toughness and fatigue strength. Recommended materials: 42CrMo, H13 hot-work tool steels—offering an excellent balance of strength and ductility for extended tool life.

For soft, ductile materials, tooling must feature an extremely smooth surface to minimize friction and prevent scratching, ensuring excellent part appearance. Key indicators: surface finish and anti-adhesion properties. Recommended materials: CrWMn, S136 stainless steel, mirror-polished to significantly improve forming quality.

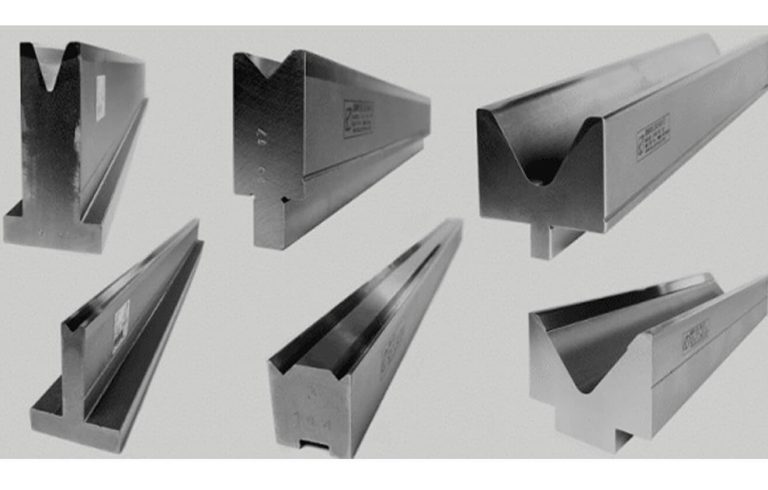

Different bending methods require specific geometric configurations, strength levels, and surface finishes. For example, during radius bending, the tooling must have excellent anti-adhesion performance to prevent surface impressions during stretching. In acute-angle bending, the punch tip must possess extremely high hardness and fracture resistance to withstand localized high pressure.

Tooling must fully match the machine’s tonnage, bed length, throat depth, and open height. Mismatched tooling can cause equipment overload, accelerated wear, or in severe cases, tool breakage and permanent machine damage. Thus, the real definition of “best” tooling is a solution that provides sustained, high-precision output with maximum efficiency, stability, and safety under specific working conditions, while minimizing total cost of ownership (TCO).

Tooling selection should not rely on intuition or experience—it requires a disciplined, replicable, and scientific process. The following five-step framework will guide you from material analysis to long-term investment evaluation, eliminating guesswork and maximizing value at every decision.

Step 1: In-Depth Material Analysis

Every design begins with material understanding. Before choosing any tool, analyze your material like a materials scientist by identifying the four fundamental “genetic markers” that determine bending success.

Tensile Strength – The Key to Tonnage Requirements

Tensile strength determines the bending force required. Advanced high-strength steels (AHSS) can have several times the tensile strength of mild steel, requiring higher bending forces and tougher, more wear-resistant tools. Ignoring tensile strength and relying only on thickness is the top cause of premature tool wear or failure. Ensure your tonnage chart includes tensile strength as a core input variable.

Yield Strength & Springback – The Angle Control Factor

Yield strength defines how much the material “remembers” its original shape after bending—i.e., springback. Hard materials like stainless steel may spring back 2–3°, while soft aluminum has almost none. To achieve accurate 90° bends in high-springback materials, use a slightly sharper punch (88° or even 85°) to compensate. Ignoring springback leads to endless re-adjustments and wasted setup time.

Ductility & Minimum Bend Radius – The Crack Prevention Rule

Ductility determines the minimum internal bend radius before cracking occurs. A common guideline suggests that the ideal internal radius equals material thickness. Using too sharp a punch to force smaller radii overstretches the outer surface, causing cracks. The punch tip radius must therefore be equal to or greater than the material’s minimum bend radius—a non-negotiable principle for product integrity.

Surface Condition – The Guardian of Aesthetics

Surface coatings such as galvanized, painted, anodized, or mirror finishes directly affect friction between the sheet and tooling. When bending mirror stainless steel or anodized aluminum, even tiny defects can cause scratches. Use highly polished tools (Ra < 0.2 μm), low-friction coatings such as TiN, or protective film tooling to maintain flawless surface quality.

Step 2: Define Bending Geometry Accurately

After understanding material properties, translate your design geometry into tooling parameters. Focus on the three core bending dimensions while mastering the “8× rule.”

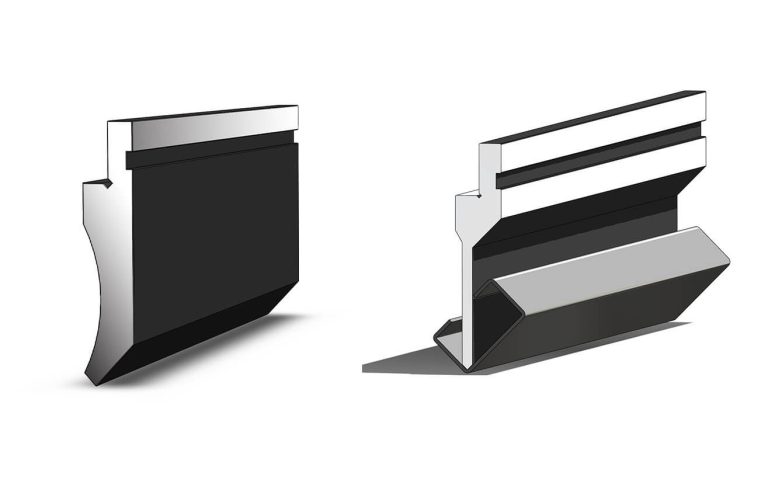

Bend Angle & Process Type

Decide whether you need 90°, acute, or obtuse bends. This determines whether you use air bending, bottoming, or coining, and defines the required punch and die angles.

Controlling Internal Radius

In air bending, the internal radius depends mainly on the die opening (V-width), not just punch tip radius: internal radius ≈ V-opening × 0.16. Choosing different V-openings allows precise radius control—one of modern bending’s greatest advantages.

The “8× Rule” Reconsidered

Common rule: V-opening = material thickness × 8, but real experts know when to adjust. For thick plate (>10 mm): use 10–12× for more contact and stress distribution. For soft metals such as aluminum: use about 6× for smaller radii. For tight-radius bends: use narrower dies but recalculate tonnage to stay within safe limits.

Minimum Flange Length

Flange length must be at least 70% of the V-opening to rest properly on die shoulders. Shorter flanges fall into the die, preventing proper forming—an essential design consideration.

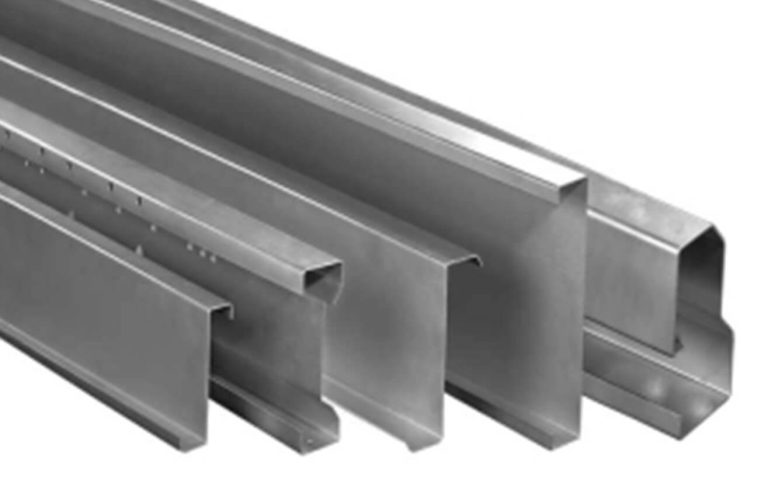

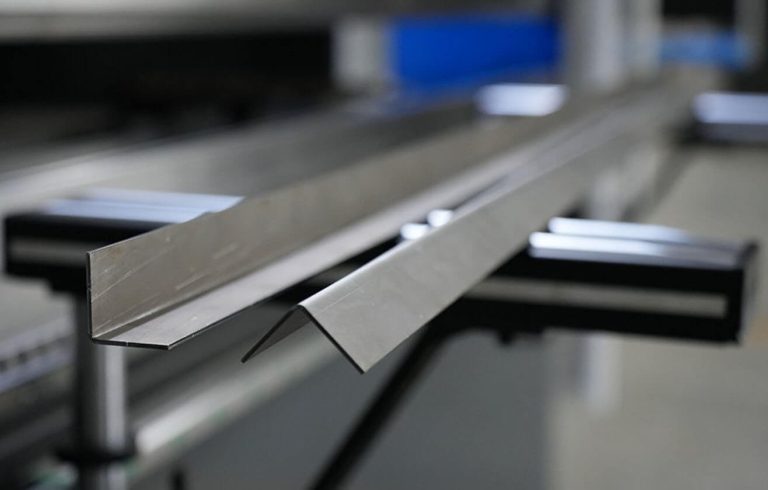

Step 3: Match Tooling with Machine Parameters

Tooling and the press brake form a single system. Even premium tooling fails if incompatible with machine specs. Tonnage must stay below the lesser of machine or tool capacity with at least 20% safety margin. Open height must accommodate tooling and part clearance when the ram is fully raised. Stroke must allow full bending and part removal. Clamping type—American, European, or WILA/Trumpf—must match the machine’s clamping system. Failure in compatibility can cause precision loss, tool loosening, or even catastrophic machine damage.

Step 4: Evaluate Tool Material, Hardness & Coating

Tool quality depends on base material, heat treatment, and surface coating.

Material Selection – Balancing Toughness & Wear Resistance

42CrMo: versatile and economical; after heat treatment reaches HRC 47±2, offering excellent balance of toughness and wear resistance.

Cr12MoV: the wear specialist. High-carbon, high-chrome steel reaching up to HRC 60 for stainless or high-volume production.

Carbide: the ultimate champion. Extremely hard and durable but expensive and brittle—ideal for high-precision applications.

The Hardness-Toughness Paradox

Hardness provides wear resistance, but too much sacrifices toughness, leading to brittle fractures. Ideal hardness must match the material’s strength—durable under dynamic loads without cracking.

Coatings – The Performance Multiplier

TiN (Titanium Nitride): classic golden coating, boosts hardness, reduces friction, and prevents sticking—perfect for aluminum and stainless steel.

DLC (Diamond-Like Carbon): ultra-low friction and high hardness, ideal for nonferrous metals to avoid scratching and sticking.

Step 5: Balance Initial Cost and Long-Term Value (LTV)

Shift perspective—from a buyer’s cost mindset to an investor’s value mindset. The cheapest tooling often becomes the most expensive during production. Evaluate Total Cost of Ownership (TCO) and Long-Term Value (LTV) rather than initial price.

TCO/LTV Evaluation Framework

Setup Time: low-precision tools require multiple test bends, adding over 30 minutes of downtime per setup. High-end tools offer plug-and-play precision, reducing setup time from hours to minutes.

Scrap & Rework Rate: low-grade tools cause unstable angles and scratches, leading to 5–10% scrap. High-end tools reduce waste below 1%, boosting profit and yield.

Tool Life: cheap tools wear quickly (few thousand cycles). Premium tools last hundreds of thousands, lowering lifetime cost.

Machine Wear: poor tool design causes uneven stress, accelerating wear and shortening maintenance intervals by 20%. High-quality tools distribute load evenly, protecting million-dollar machines.

Safety: low-grade tools risk cracking and injuring operators; premium tools ensure fail-safe performance and workplace safety.

By applying this five-step framework, you elevate tooling selection from a purchasing task to a data-driven strategic decision—optimizing production flow, minimizing hidden costs, and creating a durable competitive edge.

Our exploration of the “best press brake tooling” goes beyond brands or models. It builds a strategic enterprise-level framework, redefining tooling as a core asset balancing accuracy, efficiency, and cost—not a consumable. By understanding tooling types—from punches and dies to clamping systems—and following the five-step process covering material analysis, bending geometry, machine compatibility, material and coating evaluation, and cost-value balance, manufacturers can achieve sustained excellence. Proper installation, preventive maintenance, and troubleshooting protect your assets, ensuring long life and consistent quality. This holistic approach transforms tooling selection into a strategic pillar of manufacturing excellence, shifting focus from buying tools to investing in production assets. For expert consultation to guide your tooling strategy and maximize ROI, contact us today.

Preencha as informações abaixo para receber um orçamento gratuito e uma brochura do produto. Responderemos dentro de 24 horas!