Sobre nós

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

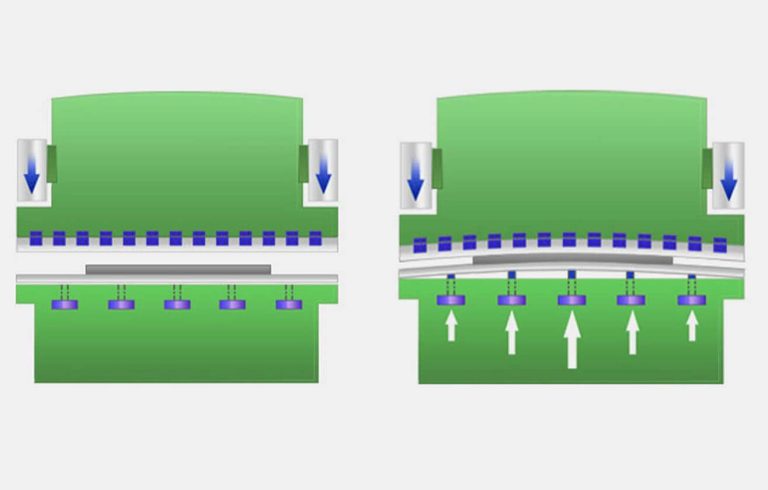

When a press brake starts bending, the beam and worktable must bear a load. This load causes certain deformation in both the worktable and the beam. To achieve precise and repeatable forming results, a deflection crowning system must be added to the press brake. Without deflection crowning, deformation may occur at the center of the workpiece when it is bent along the entire worktable. Particularly for CNC press brakes with a bending length over 2.4 meters and a pressure exceeding 80 tons, a deflection crowning system is necessary to maintain consistent bending angles throughout the entire workpiece.

Principle of the Crowning System

Modern CNC press brake systems generally use a fully closed-loop servo-hydraulic CNC system to control the position of the working beam. At both ends of the beam, position controllers are installed at the lower ends of the left and right hydraulic cylinders to precisely monitor and control their lifting positions. Each cylinder is equipped with a servo valve at the top, achieving control precision up to 0.01 mm. During bending, the servo-hydraulic system controls the cylinders according to programmed data to ensure they reach accurate positions, achieving the correct bending angle for the workpiece.

However, under load, the press brake tends to deform, especially in the center of the machine. This deformation causes the bending angle at the center to differ from that at both ends. If left uncorrected, the angular error increases as the machine length increases. To offset this, a crowning device is installed to generate a force opposite to the deflection, thus balancing the bending error. This device is known as the crowning system.

Crowning systems have been applied to press brakes since the 1980s, primarily in large-scale and high-strength bending operations where deflection errors are more pronounced. Before the invention of crowning systems, some manufacturers used pre-crowned worktables to control deflection, achieving at most about 75% accuracy.

Today, with the advancement of CNC systems, the CNC-controlled crowning system allows operators to simply input parameters such as sheet length, thickness, and material yield strength. The system automatically calculates the required crowning amount and applies it to the worktable. These parameters can be stored and reused for repeated bending operations.

As shown in the diagram, during the metal bending process, the press brake ram moves upward while the bed moves downward.

Deflection Crowning:

To improve bending accuracy and eliminate angle errors caused by deformation of the ram and worktable, deflection crowning is necessary. The press brake can be equipped with a crowning device that generates an opposite force to balance deflection. Since large metal sheets tend to have greater deflection errors, such crowning systems are commonly installed for bending large or high-strength sheets.

Selection of Crowning Systems

The need for crowning is proportional to the tonnage of the machine. Therefore, crowning systems are typically used in high-tonnage, high-strength press brakes, though they can also be used in lower-tonnage machines. The longer the worktable and ram, the greater the deflection.

There are two commonly used crowning methods: hydraulic crowning and mechanical crowning. Both methods create upward elastic deformation in the middle of the worktable to offset deflection caused by deformation of the ram and table.

Mechanical crowning is usually an optional device, while hydraulic crowning is a standard built-in system. In modern press brakes, there are three main types of crowning systems: hydraulic, mechanical, and electric crowning. The following sections explain the principles, advantages, and disadvantages of each.

Coroamento hidráulico

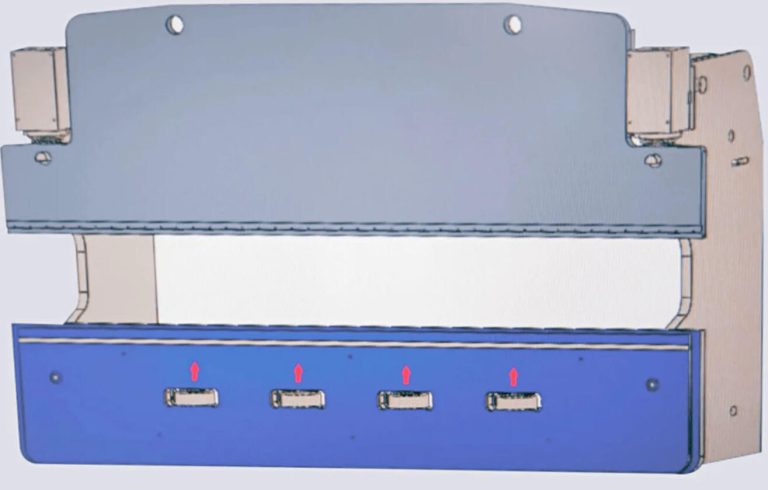

Hydraulic crowning requires a set of oil cylinders installed under the worktable of the press brake. The position and size of each cylinder are designed based on finite element analysis (FEA) of the ram and worktable to determine the deflection pressure curve.

Hydraulic crowning works through relative displacement among the front, middle, and rear vertical plates to compensate for the neutral plate. The principle is to use the elastic deformation of the steel plate itself to generate bulging, with the bulging amount adjustable within the elastic range of the worktable.

When the ram and worktable deform during bending, the hydraulic system transmits pressure to the crowning cylinders. The ram and worktable then undergo crowning deformation, reducing the impact of machine deflection on the sheet metal. However, the hydraulic system cannot provide uniform crowning for the entire worktable; local crowning depends on the position of the cylinders. Some press brakes have only one cylinder at the center, while others use multiple cylinders. All cylinders share a single pressure circuit, so the pressure is evenly distributed among them.

CNC hydraulic crowning sets parameters in the CNC system according to the workpiece’s length, thickness, and other data. The machine’s computer system calculates the necessary crowning value and sends the command to the amplifier. The proportional valve then receives the signal and controls the oil cylinders under the table to perform crowning, reducing sheet deflection during bending.

Hydraulic crowning systems are complex and may experience issues such as oil leakage or loose seals. These problems affect the crowning amount each time, leading to inconsistent processing results.

Advantages and Limitations: The main advantage of hydraulic crowning is that it does not suffer from wear over time, whereas mechanical systems do. Compared to mechanical systems, hydraulic crowning provides more precise control and real-time tonnage adjustment. However, it is more expensive and complex, requiring skilled operators and regular maintenance.

Coroamento mecânico

Mechanical crowning uses wedges to adjust the worktable. Wedges can be individual or arranged in multiple groups. Systems with multiple wedges have more crowning points than typical three-point hydraulic systems and no blind crowning zones.

Mechanical crowning can cover the entire worktable. Crowning can be performed at any point along the table length through wedge adjustment. The CNC system calculates the required crowning force based on the load during bending. This force causes deflection deformation in the ram and vertical plate of the worktable.

The system automatically controls the relative movement of the wedges to effectively compensate for natural deflection caused by the ram and worktable. The resulting workpieces are highly accurate with minimal differences between sheets, making it ideal for batch production.

Compared with hydraulic systems, mechanical crowning offers advantages such as no oil leakage, lower failure rate, and environmental friendliness. It uses linear scales to measure feedback signal positions, and digital control ensures more accurate crowning values. However, over time, wedge wear may affect crowning accuracy.

Mechanical crowning requires a higher skill level from the operator. For workpieces requiring multiple bending steps, real-time adjustments are needed. Even experienced operators may make unpredictable errors, so mechanical crowning demands high operational precision. For single-step bending or experienced operators, mechanical crowning can be a good choice for improving accuracy.

Comparison Between Hydraulic and Mechanical Crowning

Hydraulic Crowning – Advantages:

Hydraulic crowning does not experience wear over time, which ensures long-term stability in performance. Compared to mechanical crowning, it offers precise control and allows real-time adjustment of tonnage, making it suitable for applications that require frequent parameter changes or adaptive bending compensation.

Hydraulic Crowning – Disadvantages:

The crowning effect cannot cover the entire worktable, and the crowning amount in specific areas depends on the position of the oil cylinders. Additionally, the system is relatively complex and may experience issues such as oil leakage and loose sealing components, which can affect the crowning consistency and lead to variations in sheet metal processing results.

Mechanical Crowning – Advantages:

Mechanical crowning can achieve crowning across the entire length of the worktable. It allows deviation correction at any point along the working table through wedge adjustment. It provides high bending accuracy, with minimal variation between sheets, making it ideal for batch production. Furthermore, it is oil-free, has a low failure rate, and is more environmentally friendly compared to hydraulic crowning systems.

Mechanical Crowning – Disadvantages:

Wedges may experience wear over time, which can reduce crowning accuracy. The system requires a high level of operational skill. When a workpiece requires multiple bending steps, the operator must perform real-time adjustments. Even experienced operators may encounter unpredictable errors, which means that mechanical crowning places high demands on operational precision.

Electric Crowning System

The electric crowning system uses motors for fast and precise adjustments, often integrated with advanced software and CNC systems. It provides high accuracy, efficiency, and real-time monitoring, improving productivity and quality. However, it is complex, expensive, and requires regular maintenance and skilled operators.

Conclusão

In summary, crowning plays a crucial role in press brake manufacturing. By setting proper crowning parameters, springback can be effectively reduced, improving bending accuracy and ensuring product quality.

With rapid technological advancement, the integration of advanced sensors, data analytics, and machine learning into press brakes will enable real-time, dynamic, and adaptive crowning control, further enhancing the accuracy and efficiency of press brake operations.