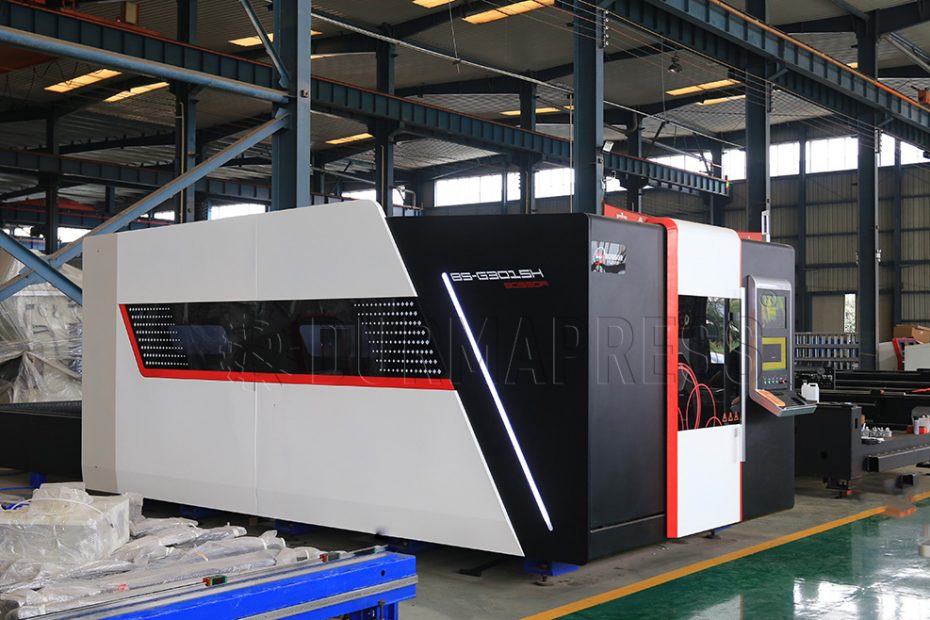

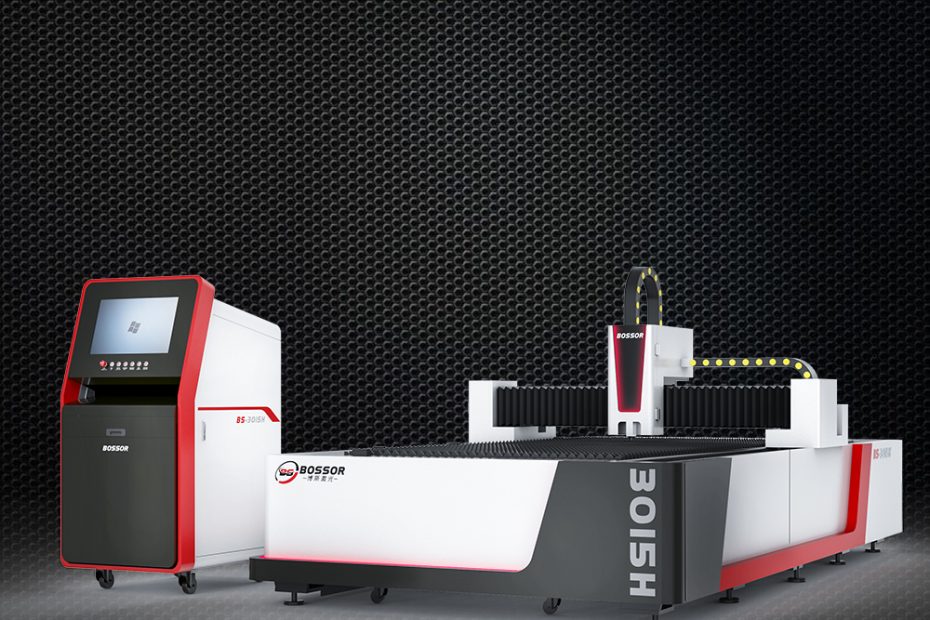

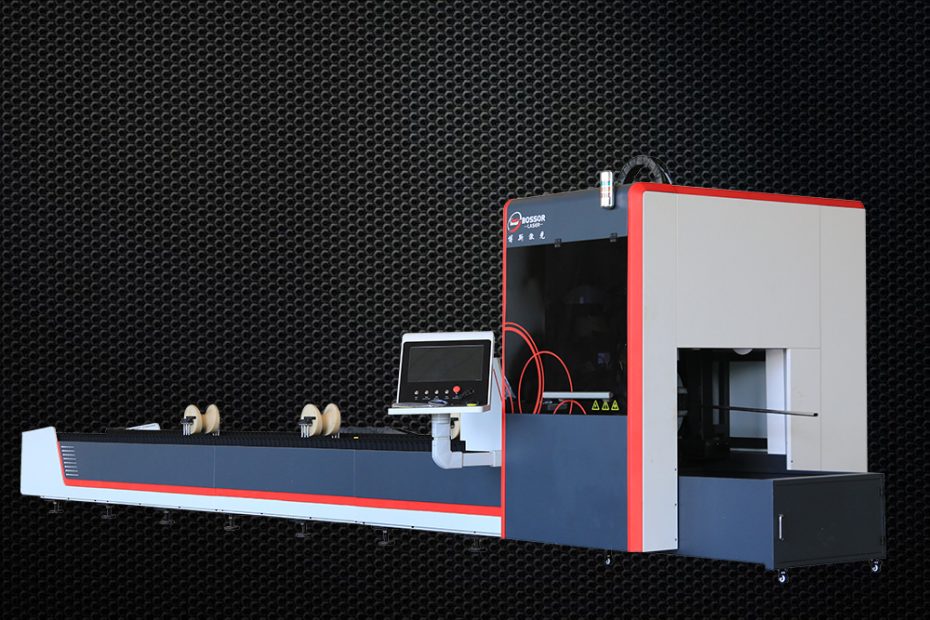

A direção de aplicação do equipamento de corte a laser inclui principalmente as três categorias seguintes

Um é usado para decoração, publicidade, lâmpadas, utensílios de cozinha, peças de chapa fina, armário elétrico, painel de elevador, placa de engenharia, materiais de processamento de armário de interrutor alto e baixo, este tipo de material é geralmente fino, máquina de corte a laser de metal que é bom, espessura é 1-5mm material de placa de aço inoxidável, com máquina de corte a laser de média potência pode ser cortado equipamento de corte a laser, Este tipo de corte de material pode ser considerado para comprar máquina de corte a laser YAG ou máquina de corte a laser de fibra 500W. O segundo... Ler mais "A direção de aplicação do equipamento de corte a laser inclui principalmente as três categorias seguintes