Como pode o sistema MES eliminar a ineficiência no fabrico de chapas metálicas para automóveis?

Na cadeia de fabrico de automóveis, a chapa metálica é como o forjador do "esqueleto", e a sua eficiência e qualidade estão diretamente relacionadas com a qualidade e a velocidade de entrega de todo o veículo. No entanto, no modo de gestão tradicional, o atraso da informação, a "caixa negra" do processo, o desperdício de recursos... continuam a incomodar a sua oficina de chapas metálicas? É hora de deixar o sistema MES injetar inteligência na sua fabricação de chapas metálicas! Que valor pode trazer o sistema MES? Se o resumirmos de uma forma concisa, por onde devemos começar?

.jpg)

Que valor pode trazer o sistema MES

O conteúdo que se segue é uma conversa com especialistas da indústria sobre o valor dos sistemas MES. "Penso que o valor dos sistemas MES para a indústria transformadora se reflecte principalmente em três aspectos, que são como os três pontos de apoio de um banco de três pernas." - Dan Meier.

1. consistência

Assegurar que cada produção segue os mesmos padrões. Do ponto de vista do sistema MES, é necessário definir claramente o fluxo do processo, a entrega do equipamento de processamento a pedido, a configuração dos parâmetros do programa de acordo com as normas e os parâmetros da receita do processo para garantir a consistência de cada execução.

2. melhorar a eficiência da produção

Sob a premissa de garantir a consistência, a melhoria da eficiência da produção é a parte da eficiência da produção. Como melhorar a eficiência da produção? Especificamente, inclui a redução do ciclo de produção, a otimização do tempo de processo e a identificação e atenuação de estrangulamentos.

3. garantir a qualidade do produto

Garantir a qualidade dos produtos, assegurando a coerência e a produção em massa a alta velocidade. A qualidade deve ser melhorada porque os produtos defeituosos na produção em massa a alta velocidade podem ter consequências graves.

.jpg)

.jpg)

Dan Meier compara o fabrico inteligente a um banco de três pernas: muitos sistemas tratam de áreas diferentes, mas o verdadeiro valor advém da sua coordenação integrada. Para além do MES e da produtividade da fábrica, as decisões automatizadas devem apoiar os objectivos comerciais - principalmente fornecer produtos de qualidade e garantir a rentabilidade do cliente. Isto requer um sistema de avaliação multidimensional, com dois indicadores principais: aproximar-se de zero defeitos e maximizar o ROI em activos, equipamento, pessoal e processos.

David Hanny sublinha que o fabrico inteligente deve criar valor comercial através da integração de sistemas, da colaboração multiplataformas e de tecnologias avançadas que aumentem a eficiência. A tomada de decisões em tempo real ajuda a melhorar a capacidade de resposta e a previsibilidade, como destaca Madhav Kidambi.

Selim Nahas salienta que a SmartFactory permite uma produção impossível ou insustentável com os métodos tradicionais. O sucesso depende da sensibilização do pessoal, da integração técnica, da escalabilidade e do controlo dos custos. Em última análise, a SmartFactory equilibra pessoas, tecnologia e economia - os pilares fundamentais para a avaliação de qualquer sistema.

.jpg)

.jpg)

Pontos problemáticos da gestão tradicional de chapas metálicas

1. programação do caos

Os planos não conseguem acompanhar as mudanças? As encomendas são frequentemente inseridas, a programação manual da produção é como "andar numa corda bamba", o equipamento está ocupado de forma irregular e os processos com estrangulamentos são difíceis de prever.

2.Progresso de produção pouco claro

O progresso não é claro? Para que processo foi transferida uma determinada peça de trabalho? Existe algum atraso? Qual é o resultado da inspeção de qualidade? Todos eles dependem de relatórios manuais, que se atrasam e são propensos a erros.

3. difícil rastreabilidade da qualidade

O rastreio da qualidade é como "encontrar uma agulha num palheiro"? Se encontrar uma peça de chapa metálica defeituosa e pretender localizar que equipamento, que operador ou que lote de materiais causou o problema? É moroso e trabalhoso procurar em registos em papel e pode até não ter forma de o encontrar.

4. tempo de inatividade não planeado do equipamento

O equipamento é colocado em funcionamento com "defeitos"? O equipamento só é desligado para manutenção depois de se avariar, e a resposta da manutenção é lenta, resultando em grandes perdas devido a paragens não planeadas.

5. fluxo de material opaco

O fluxo de materiais depende do "grito" dos trabalhadores? O inventário opaco de matérias-primas, produtos semi-acabados e produtos acabados pode facilmente levar a atrasos ou faltas, afectando a continuidade da produção.

6. contabilidade de custos inexacta

A contabilidade de custos depende inteiramente de estimativas manuais? É difícil contar com precisão as horas de trabalho, o consumo de energia do equipamento e o consumo de materiais, e o controlo de custos carece de suporte de dados. Estes pontos problemáticos não só reduzem a eficiência e aumentam os custos, como também são susceptíveis de afetar a qualidade dos produtos e a capacidade de entrega atempada.

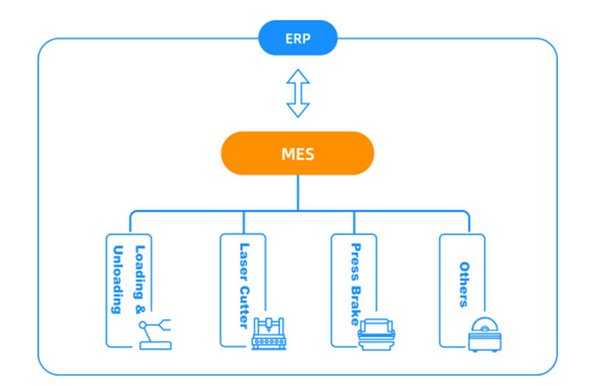

O MES para chapas metálicas para automóveis permite um fabrico inteligente

O MES (Manufacturing Execution System) é o "nervo" que liga o planeamento de nível superior (ERP) da empresa aos equipamentos de automatização de nível inferior (PLC/CNC). O MES adaptou um conjunto de soluções de gestão digital, transparente e inteligente para as oficinas de chapas metálicas:

1) Programação inteligente da produção e expedição dinâmica

O MES optimiza automaticamente a programação com base na capacidade do equipamento, no estado do molde, na integridade do material e na prioridade da encomenda, e responde a alterações como encomendas inseridas e falhas de equipamento em tempo real, ajustando dinamicamente a atribuição de tarefas. Resultado: Melhor utilização do equipamento, aviso prévio de processos com estrangulamento e datas de entrega mais controláveis.

2. rastreabilidade transparente de todo o processo

Através da ligação por código de barras/RFID/equipamento, o fluxo do processo, os parâmetros de processamento (como a estampagem, o ângulo de dobragem), os operadores, os resultados da inspeção de qualidade, o registo de data e hora e outros dados de cada peça de chapa metálica (ou lote) são recolhidos em tempo real. Resultado: Os gestores podem "ver" a dinâmica da oficina a cada momento no escritório; qualquer problema de qualidade pode ser rastreado até à fonte em segundos, com responsabilidades claras e provas para melhoria.

3. gestão de materiais Lean

O MES monitoriza com precisão o armazenamento, a utilização e o consumo de matérias-primas, bem como o fluxo e o estado do inventário de produtos semi-acabados e produtos acabados entre vários processos. Resultado: Obter uma gestão lean "JIT" dos materiais, reduzir a ocupação do inventário e evitar paragens por falta de materiais.

4. interconexão de dispositivos e gestão da saúde

O MES integra equipamento-chave, como máquinas de perfuração CNC, máquinas de dobragem e máquinas de corte a laser, e monitoriza o estado de funcionamento do equipamento (arranque, funcionamento, paragem, lembretes) e a OEE (eficiência global do equipamento) em tempo real. Resultados: A manutenção preventiva baseada em dados reduz as falhas súbitas; analisa com precisão as causas da perda de eficiência do equipamento (como a espera de materiais, a depuração e as falhas), efectua alterações específicas e melhora a OEE.

5. operação sem papel e gestão da qualidade

As instruções de trabalho, os desenhos e os parâmetros do processo são enviados eletronicamente para o terminal da estação de trabalho ou para o ecrã do equipamento. O processo de inspeção de qualidade é normalizado e digitalizado e os resultados da inspeção são introduzidos no sistema em tempo real para gerar relatórios automaticamente. Resultado: Redução dos erros humanos e melhoria da normalização operacional; análise em tempo real dos dados de qualidade e controlo do processo SPC.

6. dados exactos orientam a tomada de decisões

O MES gera automaticamente uma variedade de relatórios de produção: progresso das encomendas, eficiência da produção, OEE do equipamento, taxa de aprovação da qualidade, consumo de material, estatísticas do tempo de trabalho, etc. Resultado: Os gestores dizem adeus ao "tomar decisões com base nas suas próprias ideias" e tomam decisões de produção, contabilidade de custos e alterações contínuas com base em dados precisos e em tempo real.

O verdadeiro valor: Os lucros das empresas de chapa metálica automóvel aumentam

A implementação do sistema MES para chapas metálicas para automóveis não só melhora a eficiência, como também provoca uma mudança qualitativa na competitividade global:

1. picos de eficiência

A taxa de utilização do equipamento aumentou em 15%-30% e o ciclo de produção foi reduzido em 20%-40%.

2. salto de qualidade

A capacidade de controlo do processo é melhorada, a taxa de aprovação na primeira tentativa é significativamente melhorada e o custo da perda de qualidade é bastante reduzido.

3. otimização dos custos

Reduzir o atraso do trabalho em curso, reduzir o desperdício de material, otimizar a afetação de mão de obra, reduzir as perdas de tempo de inatividade do equipamento e reduzir os custos globais.

4. garantia de entrega

Os planos são mais precisos, os processos são mais transparentes, as respostas às mudanças são mais ágeis e a taxa de entrega atempada aos clientes é significativamente melhorada.

5.Actualizações de gestão

Conseguir uma gestão optimizada baseada em dados e melhorar o nível operacional global e as capacidades de tomada de decisões.

.jpg)

.jpg)

Escolher o MES para chapas metálicas certo: considerações fundamentais

Nem todos os MES são adequados para a indústria de chapa metálica automóvel. Ao escolher, é necessário prestar atenção a:

1. adaptabilidade do sector

Compreende os processos de chapa metálica (perfuração, corte, dobragem, soldadura, rebitagem, etc.) e os processos empresariais? Consegue dar apoio a necessidades especiais, como a gestão de moldes complexos e a otimização de nesting?

2. capacidades de integração de equipamentos

Pode ligar-se sem problemas às principais marcas de máquinas de perfuração CNC, máquinas de dobragem, máquinas de corte a laser, robôs, etc.?

3. rastreabilidade

É possível obter a rastreabilidade de todo o processo, desde as matérias-primas até aos produtos acabados e ao nível dos parâmetros-chave do processo?

4. flexibilidade e escalabilidade

Pode adaptar-se ao modo de produção de múltiplas variedades, pequenos lotes e encomendas frequentes? Pode ser expandido de forma flexível à medida que o negócio se desenvolve?

5. capacidades de implementação e de serviço

O fornecedor tem uma vasta experiência na implementação do MES na indústria automóvel? O apoio de serviço localizado é atempado e fiável?

Conclusão

A transformação inteligente do fabrico de chapas metálicas para automóveis é uma tendência inevitável. O sistema MES já não é exclusivo das grandes empresas, mas é a única forma de a maioria das empresas de chapas metálicas para automóveis aumentarem a sua competitividade central e avançarem para um desenvolvimento de alta qualidade. Diga adeus à gestão tradicional "cega, atarefada e confusa", abrace a "transparência e controlabilidade" trazidas pelo MES e faça da sua oficina de chapa metálica um poderoso motor de fabrico de veículos!

Sobre nós

A Durmapress é especializada na conceção, fabrico e venda de vários equipamentos de processamento de metal, incluindo máquinas de dobragem, tesouras, punções, máquinas de corte a laser, etc. A empresa foi fundada em 2000. Com anos de experiência e acumulação de tecnologia. DurmaPress tornou-se uma das marcas bem conhecidas na indústria de máquinas de processamento de metal da China.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.