How CNC Control Improves Accuracy in Hydraulic Shearing Machines

- Conhecimento, Notícias

- 90+ reading now

Discover how CNC control improves cutting accuracy, repeatability, and efficiency in hydraulic shearing machines by optimizing blade clearance, stroke control, and back gauge positioning.

In modern sheet metal fabrication, cutting accuracy is no longer determined solely by machine rigidity or blade quality. As production volumes increase and material varieties expand, control systems play a decisive role in ensuring consistent, repeatable, and high-quality shearing results.

Among these systems, CNC control has become a key factor in improving accuracy in hydraulic shearing machines.

This article explains why and how CNC control improves cutting accuracy, compares CNC and manual control, and clarifies why CNC-controlled guillotine shears are widely adopted in precision metal processing.

Accuracy in shearing directly affects downstream manufacturing processes. Even small deviations during cutting can lead to:

In high-volume or high-precision fabrication, relying on operator experience alone is no longer sufficient. This is where CNC control fundamentally changes the game.

Traditional hydraulic shearing machines rely heavily on manual or semi-automatic control. While suitable for basic applications, this approach has inherent accuracy limitations.

Manual adjustments depend on the skill and judgment of the operator. Different operators may set parameters differently, leading to inconsistent results.

Blade gap is often adjusted mechanically and infrequently. Incorrect settings can cause excessive burrs, blade wear, or sheet deformation.

Manual back gauge positioning lacks fine precision, especially when frequent size changes are required.

Even if the first cut is accurate, maintaining the same accuracy across hundreds of sheets is difficult without automated parameter control.

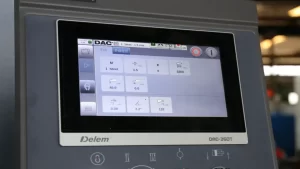

CNC (Computer Numerical Control) systems manage and coordinate key cutting parameters through programmed commands rather than manual intervention.

In a hydraulic shearing machine, CNC control typically manages:

Blade clearance

Back gauge positioning

Cutting stroke and sequence

Material thickness input

Program storage and recall

To better understand the mechanical side behind these functions, it helps to first understand how hydraulic shearing machines work and how cutting force is generated and transmitted.

Blade clearance is one of the most critical factors affecting cut quality. CNC systems automatically calculate and adjust blade gap based on material type and thickness.

This eliminates guesswork and ensures:

Improper blade clearance remains one of the most common causes of poor shearing quality, as explained in our detailed article on blade clearance adjustment.

CNC-controlled back gauges use servo motors and ball screws to achieve high positioning accuracy and repeatability.

Benefits include:

This is especially important for batch production where dimensional consistency is critical.

CNC systems optimize cutting stroke length and timing based on material thickness.

By avoiding unnecessary over-travel, CNC control helps:

With CNC control, operators can store cutting programs for different materials and thicknesses. Switching between jobs becomes a matter of selecting the correct program rather than resetting parameters manually.

This significantly reduces:

The following table highlights the accuracy-related differences between CNC and manual control in hydraulic shearing machines.

| Factor | Manual Control | CNC Control |

|---|---|---|

| Blade Clearance | Manually adjusted | Automatically calculated |

| Back Gauge Accuracy | Operator dependent | Servo-controlled |

| Repeatability | Low to moderate | High |

| Setup Time | Long | Short |

| Cutting Consistency | Variable | Stable |

| Operator Dependency | High | Low |

CNC control is most effectively applied in guillotine hydraulic shearing machines. This is mainly due to their structural characteristics:

For manufacturers handling multiple materials and thicknesses, a guillotine shearing machine with CNC control provides superior accuracy, repeatability, and long-term production stability compared to swing beam designs.

Improved accuracy is not just a technical advantage—it has direct economic benefits.

CNC-controlled accuracy helps reduce:

At the same time, faster setup and consistent cutting performance improve overall throughput and production planning efficiency.

CNC control is particularly suitable for manufacturers who:

For these users, CNC control is not a luxury—it is a practical production upgrade.

CNC control fundamentally improves accuracy in hydraulic shearing machines by eliminating manual variability and enabling precise, repeatable parameter control.

From blade clearance adjustment to back gauge positioning and cutting stroke optimization, CNC systems transform hydraulic shearing from an experience-based operation into a controlled, data-driven process.

For modern sheet metal fabrication, CNC-controlled hydraulic shears—especially guillotine designs—have become the benchmark for accuracy, efficiency, and production reliability.

Does CNC control always guarantee better accuracy?

CNC improves accuracy when combined with proper machine rigidity, blade quality, and correct parameter input.

Is CNC necessary for thin sheet cutting?

For simple applications, manual control may suffice. However, CNC ensures consistency and reduces setup time even for thin sheets.

Can CNC systems automatically control blade clearance?

Yes. One of the key advantages of CNC systems is automatic blade clearance adjustment based on material parameters.

Preencha as informações abaixo para receber um orçamento gratuito e uma brochura do produto. Responderemos dentro de 24 horas!