How To Choose Hydraulic Oil For Press Brakes: A Practical Guide For Global Users

- Conhecimento, Notícias

- 110+ reading now

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

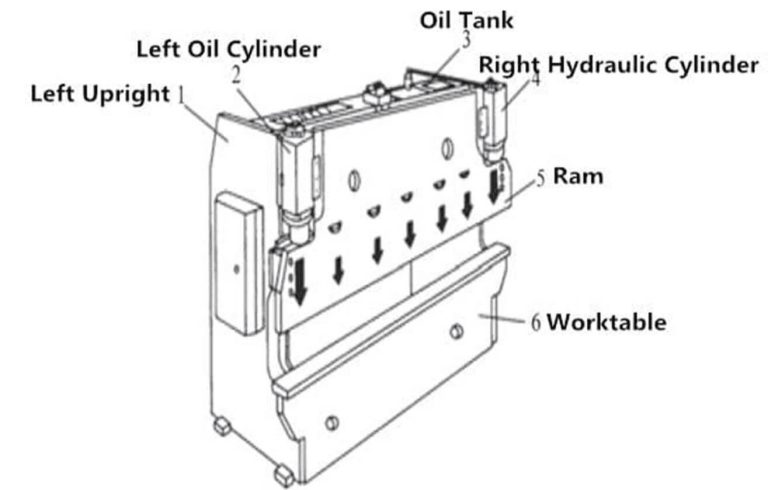

A press brake is often the most important machine in a sheet-metal workshop. It forms sharp, accurate bends in seconds, but only if the hydraulic oil inside it is correct. Oil is not a commodity; it is the machine’ s blood, its lubricant, its coolant and its sealant. Choose the wrong grade and the ram will creep, the pump will whine, the seals will leak and the repair bill will arrive sooner than expected. This article explains, in plain language, how to pick the right oil for any press brake, anywhere in the world, without referring to any specific country or climate zone.

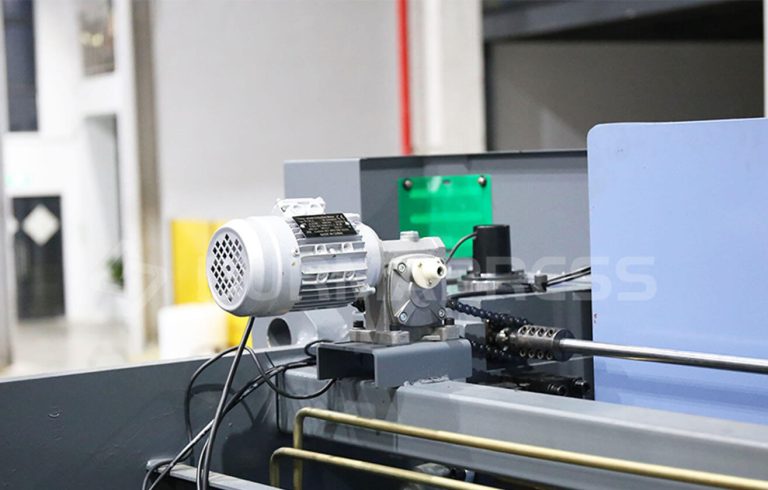

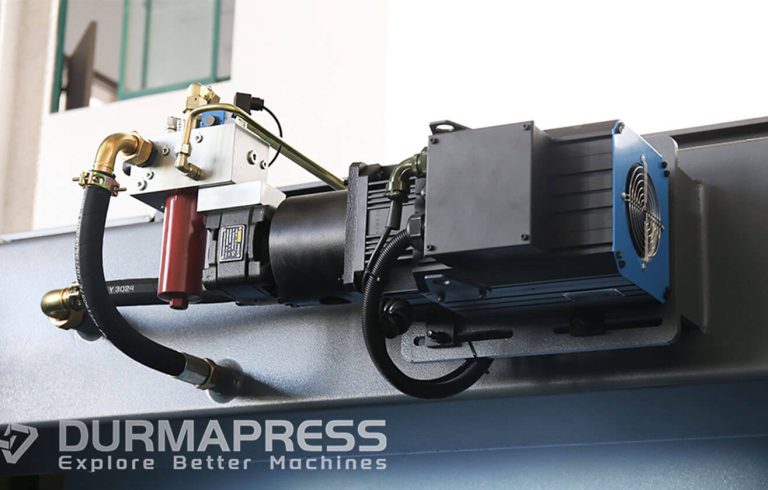

Power transmission

The electric motor drives a gear or piston pump. The pump converts mechanical energy into hydraulic energy. Oil must carry this energy, at 20 - 30 MPa (3000 - 4500 psi), through hoses and valves to the cylinders that move the ram. If the oil is too thin, internal leakage drops the ram speed and the bend angle becomes inconsistent. If the oil is too thick, the pump cavitates and the electric overload relay trips.

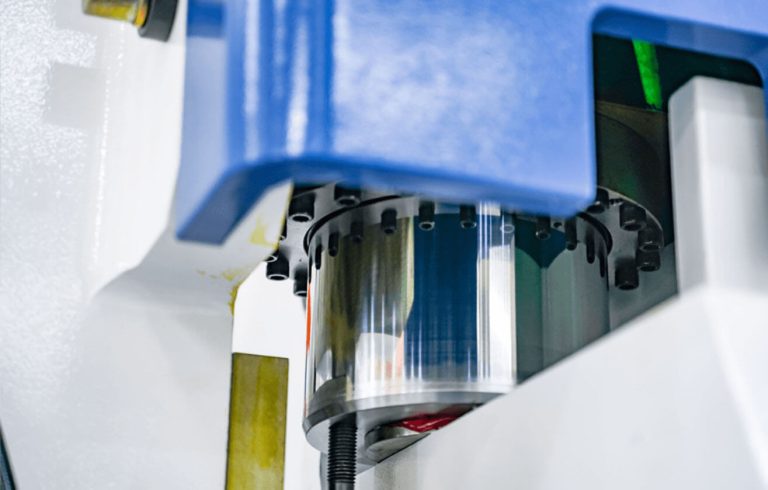

Lubrication

Piston slippers, gear teeth, spool valves and rod seals operate on oil films only a few micrometres thick. Anti-wear additives form sacrificial layers that prevent metal-to-metal contact. Without them, a pump can destroy itself in fifty hours.

Heat removal

During the press cycle, especially during pressure holding, almost all input energy becomes heat. Oil carries the heat back to the reservoir where it is dissipated through the walls or through an external cooler. Oil with a high viscosity index (VI) keeps the same thickness whether the tank is cold at start-up or hot after a long run.

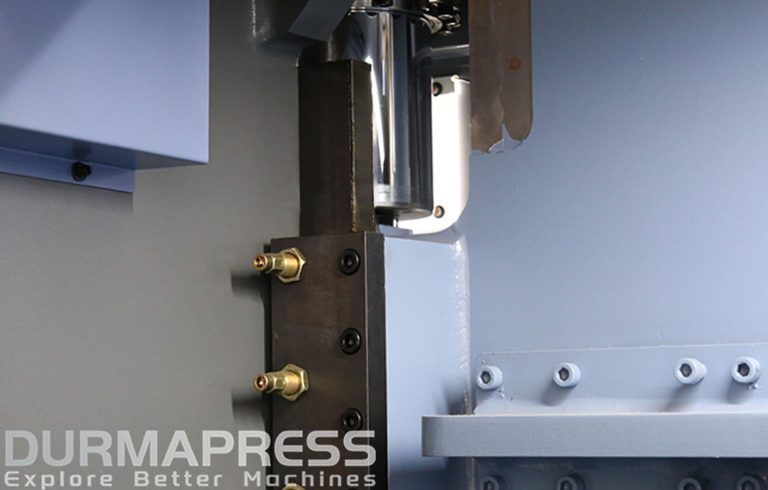

Sealing and corrosion protection

Oil must keep O-rings and lip seals supple, and it must prevent rust on cast-iron valve bodies, bronze bearings and chrome-plated rods. Some low-cost oils contain active sulphur that attacks yellow metals; some biodegradable esters attack standard nitrile rubber. Matching the oil chemistry to the elastomer chart in the machine manual is critical.

Foam and air release

Entrained air reduces bulk modulus—ram speed becomes “spongy”. Micro-dieseling of bubbles can create local hot spots of 800°C. Good oils contain <5 ppm anti-foam silicone that breaks bubbles within seconds.

Mineral HM anti-wear oil (ISO 11158, DIN 51524-2)

Base stock: paraffinic or naphthenic

Zinc dialkyl-dithiophosphate (ZDDP) anti-wear package

Typical drain interval: 2000-3000h

Cost benchmark: low

Suitable for: single-shift shops, ambient 10-70°C, fixed displacement pumps

Mineral HV or multigrade oil (DIN 51524-3)

High VI (≥140), pour-point ≤-30°C

Good for outdoor containers or unheated buildings

Drain interval: 3000 - 4000h

Cost: +10 % over HM

Semi-synthetic HG oil

Mineral oil + synthetic ester

Friction modifier added for “stick-slip” suppression

Preferred for CNC crowning systems with proportional valves

Drain interval: 4000–5000 h

Cost: +40 %

Fully synthetic PAO or ester

VI ≥160, oxidation life five times mineral oil

Operates 90-110°C continuously

Drain interval: 8000–10000 h

Cost: double mineral oil, but life-cycle cost lower when machine utilisation is high

Biodegradable synthetic ester

28-day biodegradation >60 % (OECD 301)

For food, river-front, offshore or military applications where spill fines are high

Cost: triple mineral oil

Seal compatibility must be checked (FKM recommended)

Fire-resistant fluids

Water-glycol (HFC) or polyol ester (HFDU)

Only needed when the press brake shares a power pack with furnaces or when local insurance mandates a fire-resistant fluid

Lubricity lower; pump rated pressure must be de-rated 15-20 %

Step 1: Choose the ISO viscosity grade

Measure the normal operating temperature of the tank (not the room). If you do not have a thermometer, an infrared gun on the steel wall is accurate enough.

<40°C: ISO VG 32

40-70°C: ISO VG 46

>70°C: ISO VG 68 or HV 46 synthetic

If the machine starts below -20°C, use HV 32 or PAO 32 to avoid pump cavitation. If it runs three shifts in a hot factory, use HV 68 or synthetic 46. Gear pumps tolerate a wider viscosity range than piston pumps; most press brakes use gear pumps, so VG 46 is the universal starting point.

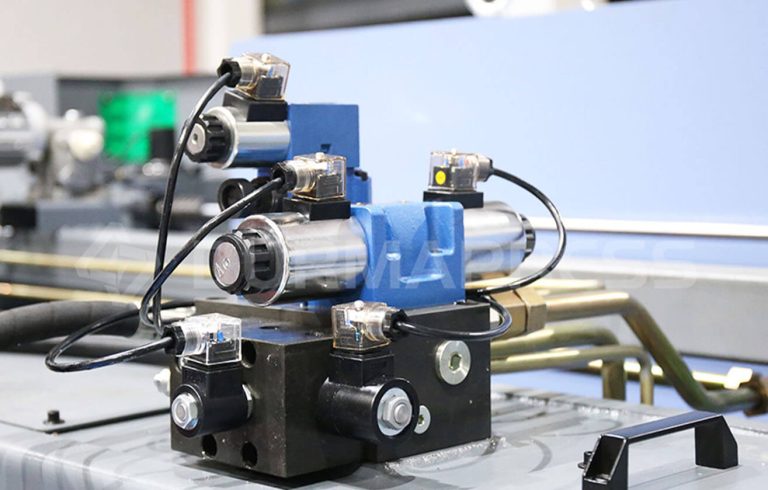

Step 2: Select the anti-wear class

For system pressure above 14 MPa (2000 psi) always specify HM, HV or HG. Do not use HL (R&O only) oils; they lack anti-wear additives and will shorten pump life by 50 %. If the machine has servo-proportional valves, choose HG to obtain the lowest static friction coefficient.

Step 3: Check the temperature span

Mineral HM oils oxidise twice as fast for every 10°C above 70°C. If your tank normally runs 80°C, a synthetic HV or HG will pay for itself in the first year by doubling oil life and halving filter changes. Conversely, if starting below -25°C, a mineral 46 oil will be thicker than 1 000 cSt and the electric motor will not start; use HV 32 or PAO 32.

Step 4: Match the seal and paint system

Standard nitrile (NBR) seals are compatible with mineral oils, PAO and most esters. FKM (Viton) seals are required for phosphate ester or for continuous >100°C. Polyurethane seals dislike water and high acid numbers; keep AN <0.2 mg KOH/g. Check the machine manual for warnings such as“zinc-free oil required”; some silver-plated valve parts suffer galvanic corrosion with ZDDP.

Step 5: Balance environment and total cost of ownership

Mineral HM 46 is cheapest if the machine runs one shift and oil disposal cost is low. Synthetic HG 46 costs twice as much but lasts four times longer and reduces unscheduled downtime; it is cheaper overall when machine utilisation exceeds two shifts. Biodegradable oil avoids environmental fines where leakage could reach water courses. Fire-resistant fluid is mandatory when local fire codes say so; factor in the 20 % pump de-rating when you size the system.

Mistake 1: Draining the factory-fill “expensive” synthetic oil and replacing it with low-cost mineral oil. Result: servo valves corrode in 500 h, bending accuracy drops, customer blames the machine.

Mistake 2: Using transformer oil because “it is also 32 cSt”. Transformer oil has no anti-wear additives; the pump score marks appear within a week.

Mistake 3: Buying “re-refined” oil with acid number 0.5 mg KOH/g. The acidic oil attacks bronze swing bearings and black sludge blocks the return filter.

Mistake 4: Mixing water-glycol and mineral oil in a shared tank. The mixture emulsifies, viscosity rises to 200 cSt, and the ram stalls.

Mistake 5: Changing only the oil in the tank, leaving 30 % old oil in the cylinders. The new oil’s additive package is instantly depleted by the acidic residue.

Mistake 6: Installing a high-pressure filter rated 6000 psi but forgetting the return filter; dirt particles circulate at high speed and valve lap marks appear.

Mistake 7: Adding an aftermarket “anti-wear booster” containing chlorinated paraffins. The chlorine forms hydrochloric acid with any moisture and destroys the copper cooler tubes.

Mistake 8: Using a zinc-containing HM oil in a system that specifies zinc-free. Silver-plated servo valve spools turn black and stick.

Mistake 9: Choosing biodegradable ester and forgetting to upgrade seals from NBR to FKM; the seals swell and block the valve ports within days.

Mistake 10: Deciding the change interval by calendar time only. After 2000 h at 90°C the oil is already beyond salvation, while another machine running 40°C could safely reach 5000 h.

Preparation: Buy new oil one week ahead and send a sample for analysis to confirm viscosity, acid number, water and particle count (ISO 4406). Have new suction, return and air breather filters ready. Bring a vacuum filter cart rated β10 ≥ 200.

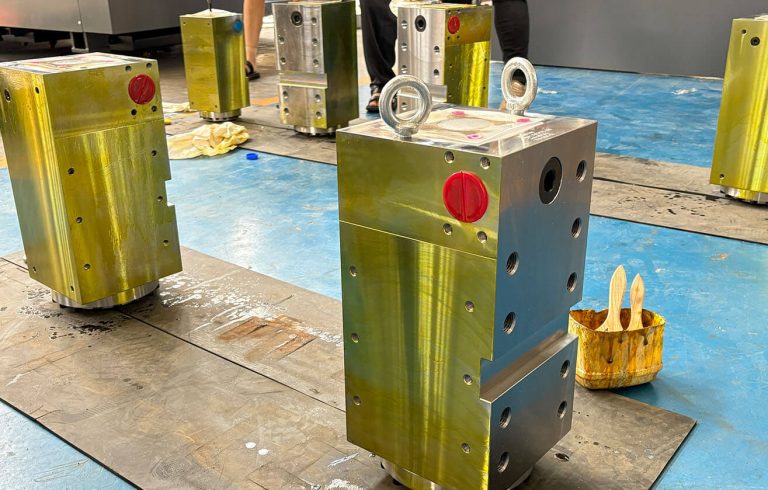

Draining: Operate the machine until the oil reaches 50°C. Move the ram to the bottom dead centre so cylinders are fully collapsed. Open the drain valve and remove the drain plug in each cylinder head. Use a vacuum wand to suck oil from the reservoir corners. Allow at least 10 min to drain completely.

Flushing: Fill with new oil to 50 % normal level. Run the pump for 5 min with the relief valve de-pressurised to create turbulent flow. Drain again. If the old oil was heavily oxidised, add 5% system cleaner, heat to 60°C and circulate 30 min, then drain.

Filter replacement: Replace all filters. Write the date on the filter canister with a paint pen.

Refill: Use the filter cart to pump new oil through a 10 µm filter into the tank. Never pour directly from the drum. Install the breather cap immediately.

Bleeding: Start the motor in jog mode. Crack the high-point vent screws on cylinders and manifolds until oil without bubbles appears. Cycle the ram slowly from top to bottom five times. Check the tank level after the oil has cooled; top up if necessary.

Test: Run the machine at maximum pressure for 5 min. Record temperature, noise level and holding pressure drop. Keep the oil analysis report in the service file.

Colour: clear honey → brown → black. Black with acid number >0.5 means change now.

Odour: sharp sour smell = oxidation; burnt smell = local overheating.

Viscosity finger test: at the same temperature, compare a fresh sample with the used oil on a metal plate; if the used oil runs noticeably faster or slower, investigate.

Foam shake test: 100 ml in a closed bottle, shake 30 s. Foam should disappear within 60 s. Persistent foam indicates antifoam depletion.

Blot test: one drop on filter paper. A dark centre with a clear halo means good dispersancy; a solid black spot means sludge is forming.

Water crackle: 10 ml in a test tube, heat with a lighter. Any crackling sound means >0.1 % water. A separate water layer means free water is present and the oil must be dehydrated or changed.

Mineral versus synthetic: the real economics

Assume a 200 L reservoir, three-shift operation, 6000 h per year.

Mineral HM 46: oil cost USD 3 per litre, life 2000 h, three changes = USD 1800 oil + 6h downtime×USD 200 = USD 3000 total.

Synthetic HV 46: oil cost USD 7 per litre, life 8000 h, one change = USD 1400 oil + 2h downtime×USD 200 = USD 1800 total.

Saving: USD 1200 per year, plus fewer filter elements, less waste oil disposal and lower component wear. The synthetic oil pays for itself in the first six months.

Disposal and environmental notes

One litre of used oil can contaminate one million litres of ground water. Never pour into the soil or sewer. Collect in labelled drums and hand to a certified recycler. Biodegradable oil is not exempt; it still contains additives and must be re-refined or incinerated. Keep the disposal certificate for five years; environmental auditors may ask for it.

Future trends

Longer-life oils: PAO/ester blends with antioxidant packages that last 15000 h are already in field trials. The target is “fill for life” matching the machine’s first major overhaul.

Greener fluids: ISO 6743-4 is preparing a new category “HEOG” for ester-based oils derived from waste cooking oil, cutting carbon footprint by 70 %.

Smart sensors: USD 200 particle counters and moisture probes now communicate by Bluetooth to a phone app. The app predicts remaining oil life and orders fresh oil automatically, eliminating guesswork.

Choosing hydraulic oil for a press brake is not complicated: match the viscosity to the operating temperature, pick the right anti-wear class, check seal compatibility and then balance price against total cost of ownership. Do that once, record it in the maintenance manual, and the machine will deliver accurate bends for a decade. Ignore it, and the first pump failure will cost more than all the oil you ever “saved”. Good oil is cheap insurance—keep it clean, keep it cool, and your press brake will never let you down.

Preencha as informações abaixo para receber um orçamento gratuito e uma brochura do produto. Responderemos dentro de 24 horas!