Sobre nós

Learn how to choose the right hydraulic press brake with this expert guide. Compare hydraulic, electric, and small press brakes, understand tonnage, tooling, CNC systems, and find reliable press brake suppliers.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Selecting the right hydraulic press brake is one of the most critical decisions for any metal fabrication business. The machine you choose will directly affect your bending accuracy, production efficiency, long-term operating costs, and your ability to take on more complex jobs. With so many models—from small press brake units to advanced electric press brake and heavy-duty hydraulic systems—the purchasing process can be overwhelming.

This guide breaks down the essential factors you must evaluate, compares machine types, and helps you identify the press brake machinery that best fits your production needs.

Why Choosing the Right Hydraulic Press Brake Matters

A press brake is the heart of most sheet metal production lines. It determines how precisely and consistently you can bend steel, stainless steel, and aluminum.

A well-selected hydraulic press brake enables:

- Accurate bending with lower rejection rates

- Faster throughput and shorter lead times

- Lower labor requirements through automation

- Safer and more stable press brake operation

- Reduced long-term operating cost

With the expansion of options—including electric press brake, hybrid systems, and compact small press brake models—buyers need a structured method to evaluate the right solution. The wrong decision may result in underpowered equipment, accuracy problems, or production bottlenecks.

Key Factors to Consider When Selecting a Press Brake

1. Bending Force & Tonnage Requirements

The first step is to determine the required tonnage. This depends on material type, thickness, bending length, and tooling design.

For example, a CNC 200T press brake is ideal for medium-thick carbon steel or stainless steel up to 4mm–6mm across long lengths. If you frequently bend high-strength steel or require larger working lengths, you may need 250T–400T or more.

General principle:

- Thin aluminum / parts < 2mm → Small press brake (20T–40T)

- General sheet metal 2–4mm → 63T–160T

- Heavy plate production → 200T–600T hydraulic press brake

Choosing insufficient tonnage leads to deformation, inaccurate angles, and accelerated machine wear.

2. Bending Length & Worktable Size

Press brakes commonly come in 1.2 m, 2.5 m, 3.2 m, 4 m, and 6 m lengths.

If your longest part is 2.4 m, selecting a 3.2 m hydraulic press brake offers flexibility without unnecessary cost.

Compact workshops or small-part manufacturers may prefer a small press brake, which saves space and lowers energy consumption while retaining precision.

3. Material Type & Production Volume

Different materials require different bending forces and machine rigidity:

- Stainless steel: Higher strength → requires higher tonnage

- Carbon steel: Standard tonnage, stable performance

- Aluminum: Lower tonnage, but high precision needed

Production volume also determines the needed automation level:

- Low volume → standard hydraulic system

- Medium to high volume → CNC with multiple axes

- Precision manufacturing → electric press brake

4. Hydraulic vs Electric Press Brake

Both systems serve different production needs.

Prensa hidráulica

- Best for thick material

- High tonnage range

- Stable and durable

- Cost-effective for general manufacturing

Electric Press Brake

- Faster and extremely energy-efficient

- Ideal for small parts and high-cycle precision work

- Low noise, low maintenance

- Higher initial investment

Hybrid systems combine hydraulic power with electric control, offering better speed and lower energy consumption.If you are considering high-speed precision bending, explore our electric press brake solutions.

5.CNC System & Automation Level

The CNC controller significantly affects ease of use and consistency.

Common systems include: Delem DA53T / DA58T / DA66T/ DA69S, ESA, and Cybelec.

Higher-axis machines (e.g., 4+1 axis, 6+1 axis) allow:

- Automated bend sequence calculation

- Angle compensation

- Faster setup and higher repeatability

A modern CNC simplifies press brake operation even for inexperienced operators.

6. Backgauge Accuracy & Mechanical Structure

The backgauge is responsible for positioning material accurately.

Look for:

- Servo motor drive

- Ball screw or linear guide

- Rigid mechanical frame

- Fast positioning speed

These elements determine the long-term accuracy of your metal brake machine and directly affect bending quality.

7. Tooling Selection (Punch & Die)

Good tooling is as important as the machine.

Choosing the right punch, V-die size, and gooseneck tools ensures accurate bending and reduces marks on the workpiece.

Custom tooling may be required for deep boxes, U-shapes, or special industrial components.View compatible press brake tooling to improve bending accuracy.

Common Press Brake Options You Should Compare

Prensa hidráulica

Perfect for heavy-duty and general fabrication.

Most cost-effective for thick materials.

Electric Press Brake

Best for high precision, small components, and automated production lines.

Lower long-term energy cost.

Small Press Brake

Designed for small workshops, R&D labs, lighting boxes, and small-batch parts.

Hydraulic Shearing Machine

Many factories pair a press brake with a máquina de corte hidráulico to:

- Ensure precise sheet cutting before bending

- Reduce burrs and improve bending quality

- Streamline production into a complete metal processing line

Basic Press Brake Operation Every Buyer Should Know

Understanding press brake operation helps buyers evaluate machine usability and safety more accurately. During setup and calibration, operators install the punch and die, set the bending length, adjust the backgauge, and verify all safety distances to ensure the machine is prepared for accurate bending. Programming a press brake involves setting the bending angle, defining the bending sequence, adjusting pressure and speed, and applying the necessary springback compensation for different materials.

Regular maintenance is also essential for long-term reliability. Operators should inspect hydraulic oil and seals, clean the guides and backgauge, check electrical components, and ensure the light curtain safety system is functioning properly. This foundational knowledge allows buyers to make better purchasing decisions and ensures stable, long-term machine performance.

How to Evaluate Reliable Press Brake Suppliers

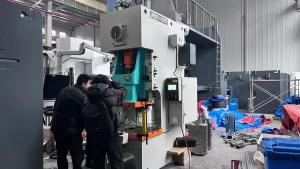

Choosing the right press brake suppliers has a direct impact on installation quality, equipment lifespan, and the level of after-sales support you receive. A reliable manufacturer should demonstrate strong factory capability, including in-house laser cutting, welding, machining processes, CNC machining centers, gantry mills, and a professional R&D team. You should also check the supplier’s certifications, such as CE, ISO, and compliance with international electrical standards, as these indicate consistent manufacturing quality.

Another important factor is customization options. Top suppliers can offer specialized solutions such as a CNC 200T press brake, tailored tooling for specific parts, automation units, or even fully robotic bending cells to support advanced production needs. Finally, consider the level of global service and spare parts availability. A dependable supplier will provide comprehensive training, on-site installation, and fast-response technical support to keep your production running smoothly.

Budget Planning: Total Cost of Ownership

Beyond purchase price, consider:

- Energy consumption (electric is lowest)

- Tooling cost

- Maintenance and lubrication

- Downtime and spare parts

Sometimes, a slightly higher upfront investment results in significantly lower long-term operating costs.

Case Studies: Which Type Fits Your Business?

- Heavy fabrication: Hydraulic press brake + hydraulic shearing machine

- Precision sheet metal factories: Electric press brake + robot automation

- Small workshops: Small press brake with standard tooling

- Industrial equipment manufacturers: CNC 200T press brake or above

Conclusion: Your Structured Selection Checklist

Before buying, evaluate:

- Material thickness & bending length

- Tonnage

- CNC level

- Automation needs

- Tooling

- Supplier reliability

A properly chosen press brake becomes a long-term asset that boosts productivity, accuracy, and profitability.Learn more about our full range of hydraulic press brakes here.

FAQ

Use material thickness × length × bending factor. Suppliers can also simulate the tonnage for your drawings.

Hydraulic = power + versatility; Electric = speed + precision + low energy usage.

Yes, as long as tonnage matches the thickness.

If you cut raw sheets before bending, it is recommended.

Basic checks daily; full inspection every 3–6 months.