Sobre nós

Transform your sheet metal shop into a Robot Arm 4.0 Factory with DurmaPress. Discover smart robotic press brake bending, higher efficiency and consistent quality.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Enabling Connectivity and Collaboration in Smart Factories

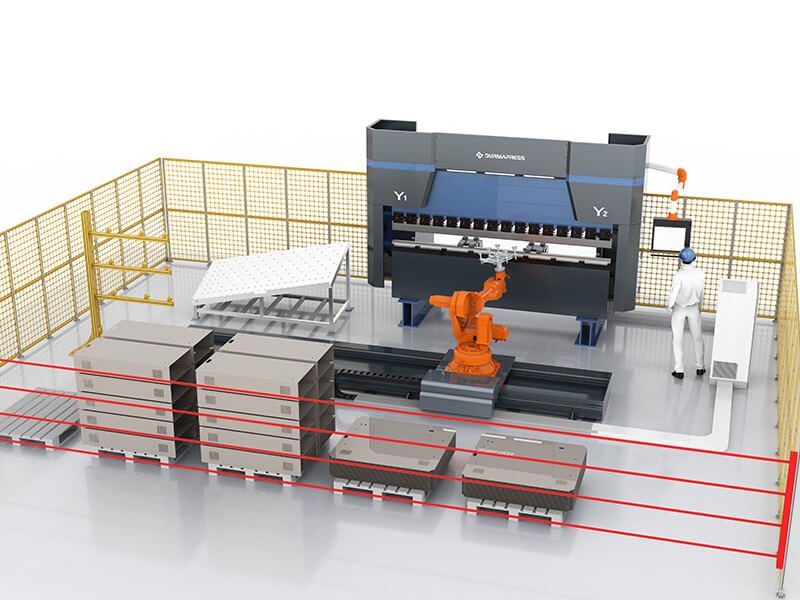

Manufacturers around the world are under pressure to deliver higher mix, lower volume sheet metal parts with shorter lead times and more consistent quality. In this context, the Robot Arm 4.0 Factory has become a powerful way to combine smart automation, connected data and deep bending expertise in one flexible production system. As a specialist in press brakes and robotic bending solutions, we provide advanced robot programming to enhance production processes. DurmaPress helps sheet metal fabricators upgrade from stand‑alone machines to fully integrated robot arm bending cells that fit the Industry 4.0 vision.

What “Robot Arm 4.0 Factory” Really Means

A Robot Arm 4.0 Factory is a smart sheet metal shop where industrial robot arms, CNC press brakes, sensors, and software are fully connected in real-time to create a cyber‑physical production system. Instead of isolated workstations, every bending cell communicates in real time with planning, quality and maintenance systems, turning each machine into a data‑driven asset.

In practical terms, this means that the robot arm, the press brake, the safety devices and even the tooling become part of a single smart cell. Programs, production orders and quality parameters are sent digitally, while live feedback from sensors and controllers helps the system self‑optimize for throughput, quality and energy usage.

From Traditional Bending Shop to Robot Arm 4.0 Cell

Typical Pain Points in Manual Bending Shops

Traditional bending shops still rely heavily on experienced operators to handle complex and heavy sheet metal parts. As product variety increases and batch sizes shrink, these shops face several challenges: skill shortages, quality variation between operators, difficult night shifts and rising labor costs.

Manual handling of large panels introduces ergonomic risks and slows down the process, especially when frequent re‑clamping or flipping is required. At the same time, customers expect shorter lead times and more stable angles, leaving little room for rework or scrap.

How a Robotic Press Brake Cell Changes the Game

A robotic press brake cell combines an industrial robot arm with a CNC press brake to automate loading, bending, flipping and unloading of sheet metal parts. In this configuration, the robot handles all part movements while the press brake focuses on achieving consistent bending angles and dimensional accuracy.

By standardizing the bending sequence and robot motions, the cell enables one‑piece‑flow, unmanned shifts and repeatable quality across different batches. Once the bending program and robot path are validated, the cell can run the same part family again and again with minimal setup time, freeing skilled operators for higher‑value tasks such as programming and process optimization.

Key Technologies Behind a Robot Arm 4.0 Factory

Connected Robot Arms and IIoT Integration

At the heart of the Robot Arm 4.0 Factory is connectivity between robots, press brakes and higher‑level systems such as MES and ERP. Industrial communication networks and open interfaces allow DurmaPress bending cells to exchange real‑time production data, job queues and diagnostic information with the rest of the factory.

This connectivity makes it possible to schedule orders dynamically, monitor OEE and energy consumption, and adjust production priorities based on actual demand. It also enables remote support and software updates, which help maintain high availability across the entire bending shop.

Vision, Sensors and Safety

Modern robot arm bending cells rely on a combination of vision systems, laser sensors and safety devices to handle parts reliably and protect people. Vision and sensors help the robot locate and grip sheet metal accurately, compensate for small position deviations and verify that the correct part is in place before each bend.

Safety scanners, light curtains and interlocks define safe zones and ensure that the collaborative interaction between humans and machines stays under control. With the right safety concept and risk assessment, operators can load pallets, change tools or inspect parts while the cell maintains a high level of protection and uptime.

Predictive Maintenance and Quality Analytics

Because every movement and bending stroke generates data, the Robot Arm 4.0 Factory opens the door to predictive maintenance and advanced quality analytics. By monitoring cycle counts, motor currents, hydraulic performance, angle corrections, and alarms over time, DurmaPress systems can highlight abnormal patterns in real-time before they lead to unexpected downtime.

At the same time, analytics on bend angles, rework rates, and scrap give engineers a clear picture of process capability and long‑term trends, driving the intelligent optimization of operations. This allows continuous improvement teams to fine‑tune parameters, standardize best‑performing setups and document the real impact of automation on quality and cost.

Designing a Robot Arm Bending Cell Around Your Press Brake

How to Evaluate If Your Factory Is Ready

Not every application needs a fully automated bending cell, so the first step is an honest assessment of your parts, volumes, workflow, and how they adapt to the industrial revolution. Key questions include: how many part families repeat regularly, what is the mix between small and large panels, how heavy are the parts, and how stable are your drawings and tolerances as you optimize your production processes.

It is also important to review available floor space, upstream and downstream processes and the level of bending expertise inside your team. Many successful customers start with one pilot robotic cell focused on a high‑impact product family, then gradually expand automation as the efficiency and benefits become clear.

Core Design Considerations

When designing a robot arm bending cell, several technical factors must be balanced to achieve stable throughput and high quality. Robot payload and reach need to match part size and weight, while gripper and fixture design must avoid scratches and ensure secure handling of thin sheets.

Cycle time targets, batch sizes, and shift patterns influence the layout of infeed pallets, stacking solutions, and buffer zones around the press brake to enhance operational efficiency. Seamless integration with existing DurmaPress CNC press brakes and upstream cutting equipment helps create a smooth material flow without bottlenecks or unnecessary manual handling.

Implementation Roadmap

A typical implementation roadmap follows four main stages: assessment, simulation and layout, on‑site commissioning, and optimization with training. During assessment, the project team defines target parts, KPIs and technical constraints, while simulation verifies robot reach, cycle times and collision‑free paths before any hardware is installed.

Commissioning and fine‑tuning on the shop floor are followed by operator and programmer training, enabling the customer team to adapt programs, introduce new parts, and maintain the cell independently. Continuous monitoring and periodic optimization ensure that the robot arm bending cell continues to deliver value as product mix and requirements evolve.

Real‑World Results from Robot Arm 4.0 Bending Lines

Robot arm bending cells are typically introduced to improve consistency, reduce labor intensity and enable unmanned shifts, especially for repetitive or heavy parts. Many users see reduced dependence on highly skilled manual operators and a more predictable bending process once the cell is stabilized.

In a typical scenario, a factory that previously needed multiple operators to run several manual press brakes can redeploy people after installing a DurmaPress robotic cell. The cell maintains stable cycle times and angle accuracy across long runs, while night‑shift production becomes more feasible thanks to reduced staffing requirements.

Beyond labor savings, customers often report lower scrap rates, fewer re‑bends, and improved traceability of bending parameters, which optimize overall operation. With detailed production records and sensor data, quality teams gain better visibility into what happened on each batch and can respond faster if a deviation occurs.

How DurmaPress Helps You Build a Robot Arm 4.0 Bending Shop

DurmaPress focuses on CNC press brakes, robotic bending cells and turnkey sheet metal automation projects designed for the Industry 4.0 era. By combining proven bending technology with industrial robot arms, smart software and standardized cell modules, the company offers a scalable path from stand‑alone machines to fully connected Robot Arm 4.0 Factories.

Open integration with major industrial controllers and factory systems allows DurmaPress solutions to fit into existing production environments with minimal disruption. Customers can start from a single robotic press brake cell and later add more cells, connect them to MES or extend automation to loading, stacking and intralogistics.

For sheet metal fabricators planning the next step of their digital transformation, a DurmaPress robotic bending solution provides a clear upgrade path. From feasibility study and simulation to on‑site commissioning, training and lifecycle support, DurmaPress helps transform a conventional bending shop into a Robot Arm 4.0 Factory ready for future growth.