Press Brake Dies and Punches: How They Affect Bending Accuracy

- Conhecimento, Notícias

- 90+ reading now

Discover how press brake dies and punches affect bending accuracy, including tool geometry, die types, and common accuracy issues.

In sheet metal bending, many manufacturers focus on machine tonnage, backgauge precision, or CNC controllers—but the most decisive factor in bending quality remains the tooling. Press brake dies and punches directly determine the bending radius, angle consistency, springback behavior, surface finish, and even material stress distribution. Even a high-end CNC press brake will struggle to produce consistent results if the tooling is mismatched, worn, poorly aligned, or geometrically unsuitable for the part design. Understanding how dies and punches interact with material fibers is the foundation for controlling accuracy and reducing scrap.Advanced CNC press brakes can only reach their full accuracy when paired with high-quality tooling. Learn more in our CNC Press Brake Guide.

Even when two sets of tools look similar, small geometric differences—especially in punch radius, die angle, and V-opening—can significantly impact bending force, angle prediction, and springback control.

The punch tip radius determines the minimum achievable inside radius and how the material flows during bending. A sharper punch increases forming pressure and creates a tighter inside radius but also risks leaving marks on softer metals like aluminum. A larger punch radius reduces cosmetic defects and helps control springback on high-strength steel. The punch shoulder angle also affects how material contacts the punch during air bending, influencing angle consistency.

The die angle (commonly 85°, 88°, or 90°) controls how the workpiece settles during bending and how much force is required. The V-opening is one of the most important parameters: the wrong V-size creates angle variation, cracking, or overbending. The general rule is to choose a V-opening approximately 6–10 times the material thickness, but different materials may require adjustments. Larger V-openings reduce tonnage but increase radius; smaller V-openings produce sharper bends but increase springback and material stress.

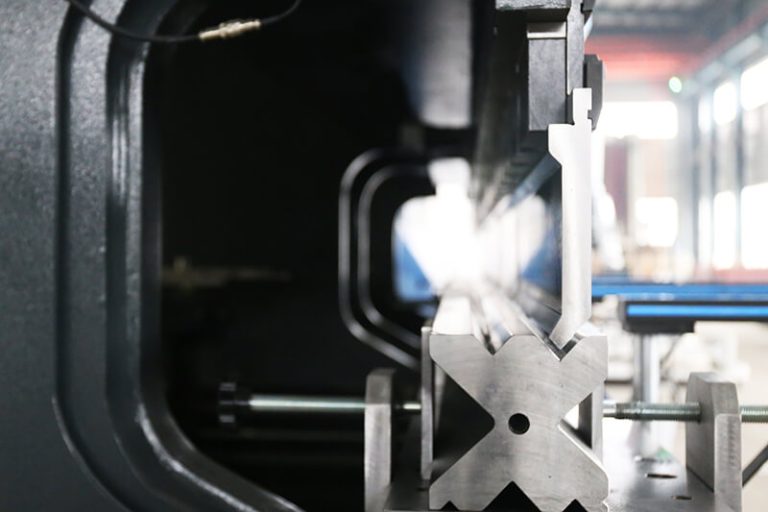

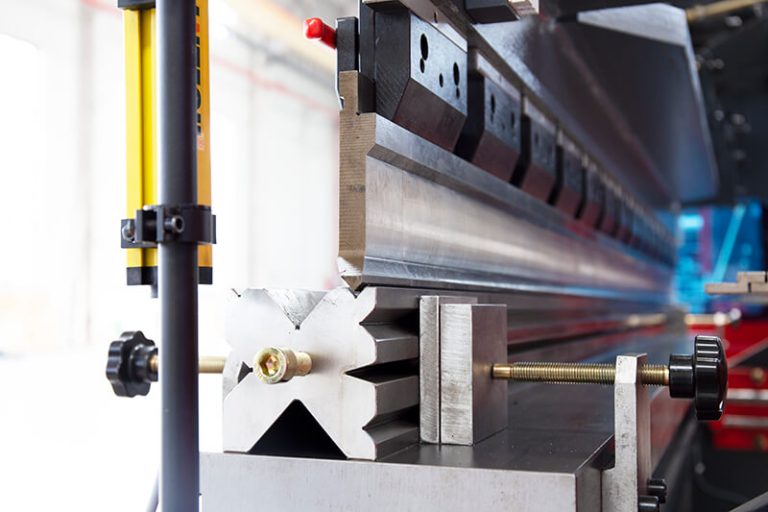

Different die types produce different bending behaviors. A single V-die is the most common choice for general sheet metal work because it provides stable support and predictable bending angles across a wide range of thicknesses. Multi-V dies add flexibility by combining several openings in one block, allowing quick adaptation to different materials without tool changes.

Acute dies (30° or 45°) are used when forming sharp angles or preparing parts for hemming. Radius dies help prevent cracking in aluminum or soft materials by spreading forming pressure and producing smooth, cosmetic bends. Hemming dies perform a two-step process—air bending followed by flattening—to create strong, folded edges widely used in enclosures and panels. Offset dies allow single-stroke Z-shaped bends and are essential for automotive and appliance components. Each die type changes how the material contacts the tooling, affecting accuracy, tonnage requirements, and final angle repeatability.For a full breakdown of common die styles and how to select them, explore our types of press brake tools and how to choose them article.

Straight punches are the standard tooling choice for most applications because they provide stable forming geometry and are compatible with a wide range of V-dies. Gooseneck punches are used when bending deep boxes or channels where the part could otherwise collide with the punch body. Acute punches allow forming of tight angles or pre-hemming bends, while radius punches are preferred for aluminum or stainless steel to reduce cracking and surface indentation.

Punch selection should always account for inside radius requirements, tonnage limits, material type, and the shape of the finished part. Choosing an incorrect punch geometry can cause angle deviations, excessive springback, indentation marks, or even tool damage.

Correct punch–die matching is one of the most important contributors to bending accuracy. The punch radius must be appropriate for both the material thickness and the die’s V-opening. The widely used “8×V rule” helps estimate bending force and angle behavior: choosing a V-opening approximately eight times the sheet thickness typically produces a good balance of radius control and surface finish.

A mismatch—such as using a small punch radius with an oversized die—introduces excessive springback and angle variation. Conversely, using a large-radius punch in a small V-opening requires high tonnage and can create over-bending or cracking. Precision bending also requires proper tool alignment and clamping, especially when using WILA or European-style quick-clamp systems. When punches and dies are correctly matched, angle accuracy improves, repeatability increases, and tonnage loads stay within safe limits.

Example Table: Punch–Die Matching Guide

| Material Thickness | Recommended V-Opening | Suitable Punch Radius |

|---|---|---|

| 1.0 mm | 8–10 mm | 0.5–1.0 mm |

| 2.0 mm | 12–16 mm | 1.0–1.5 mm |

| 3.0 mm | 24 mm | 1.5–2.0 mm |

(Values represent common industrial practice; actual selection depends on material type and bending method.)

Many bending issues originate from the tooling rather than the machine. Using a worn die leads to inconsistent V-edge geometry, causing angle drift and poor repeatability. Incorrect punch radius produces cracking, excessive springback, or cosmetic marks. A misaligned punch–die setup creates asymmetrical angles and stresses the machine. Choosing the wrong V-opening increases tonnage load, accelerates tool wear, and can even cause part deformation. Understanding these relationships allows operators to diagnose accuracy problems more effectively and reduce rework and scrap rates.

Usually because the punch radius or V-opening is mismatched, or the die edges are worn.

Air bending offers flexibility, but bottom bending provides higher angle consistency when using properly sized dies.

A small radius produces sharp bends but increases springback and risk of cracking; a larger radius improves cosmetic quality

Using a sharp punch, an undersized V-die, or tools that are not properly polished or hardened.

Preencha as informações abaixo para receber um orçamento gratuito e uma brochura do produto. Responderemos dentro de 24 horas!