Press Brake Tooling Guide: Types, Materials, Selection Tips & Maintenance

- Conhecimento, Notícias

- 90+ reading now

A complete guide to press brake tooling covering punch and die types, material options, V-opening selection, tooling standards, and essential maintenance practices.

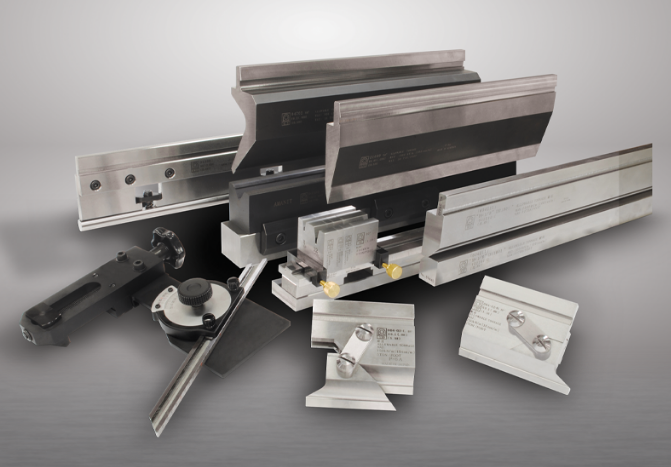

Press brake tooling directly determines bending accuracy, repeatability, edge finish, and production efficiency. Selecting the right punches and dies—and maintaining them properly—is essential for consistent sheet metal forming quality. This guide explains the major types of press brake tooling, common materials, structural design differences, selection considerations, and long-term maintenance practices for industrial fabrication environments.

Press brake tooling refers to the punches and dies installed on the upper and lower beam of a press brake to bend sheet metal into specific angles or shapes.

A standard toolset includes:

Tooling quality directly influences:

Different tooling materials determine hardness, wear resistance, cost, and precision. Below is a practical reference table:

Table 1: Common Tooling Materials Compared

| Material Type | Hardness Level | Advantages | Typical Use Cases |

|---|---|---|---|

| 42CrMo Alloy Steel | Medium–High | High strength, good durability, cost-effective | Standard punches/dies for mild steel & stainless steel |

| T8 / T10 Carbon Steel | Medium | Simple forming jobs, easy to machine | Budget tooling, light production |

| H13 Tool Steel (Heat-treated) | High | Excellent hardness, heat resistance, long service life | Heavy-duty bending, high tonnage jobs |

| Carbide Tipped Tools | Very High | Extreme wear resistance, perfect repeatability | High precision bending, thin stainless steel, mass production |

If you work with high-strength steel or thick plate, our hybrid press brake overview explains how advanced hydraulic-electric systems help protect tooling during heavy-duty bending.

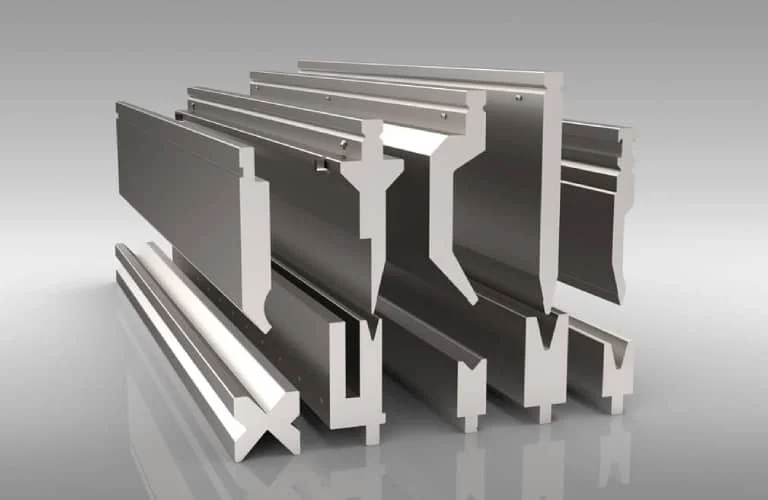

Different punch geometries allow different bend shapes. The most common punches include:

Dies determine V-opening, radius, and bend style.

Correct V-opening is critical for bending force and angle accuracy.

General rule:

V-opening = 8 × sheet thickness (t)

Table 2: Recommended V-Opening by Thickness

| Sheet Thickness (mm) | Recommended V (mm) | Notes |

|---|---|---|

| 0.5–1.0 | 6–8 | Precision bending |

| 1.5–2.0 | 12–16 | General fabrication |

| 3.0–4.0 | 24–32 | Reduces tonnage requirement |

| 6.0–8.0 | 48–64 | Heavy-duty applications |

Too small V = cracking risk

Too large V = poor angle accuracy

Press brake tooling systems follow several international standards, each optimized for different levels of precision, flexibility, and production requirements. Understanding these standards is essential for ensuring compatibility with your press brake and long-term tooling strategy.To select compatible tooling and clamping systems, refer to our comparison of metal processing machines commonly used in fabrication workshops.

European tooling is the most widely used in modern CNC press brakes due to its modularity and quick-change capability.

Key Characteristics:

Best For:

Job shops, high-mix/low-volume production, and CNC press brakes requiring flexibility.

American tooling is known for simplicity and structural robustness. It uses one-piece long tools rather than short, segmented punches and dies.

Key Characteristics:

Best For:

Heavy-duty bending, long straight bends, and cost-sensitive operations.

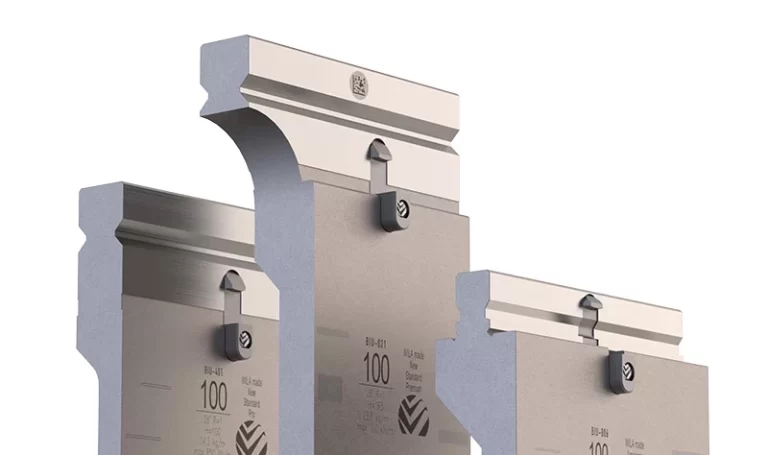

This is the premium, high-precision tooling ecosystem used in advanced CNC press brakes.

Key Characteristics:

Best For:

High-volume production lines, aerospace-grade precision, automated bending cells.

Tooling performance and lifespan greatly depend on proper maintenance. A structured maintenance program can extend tooling life by 30–50%.

Misalignment causes torsion on tools and uneven wear.

Some tools allow regrinding to restore performance.

| Defect | Possible Causes | Solutions |

|---|---|---|

| Cracking during bend | V too small / punch too sharp | Choose larger V or radius punch |

| Angle inconsistency | Tool wear / incorrect crowning | Inspect tools; adjust crowning |

| Surface marks | Hard punch on soft metal | Add radius insert |

| Excessive springback | Material too strong / tooling mismatch | Use acute tooling or narrower V |

Press brake tooling is a critical factor in achieving precision metal bending. Understanding punch and die types, selecting the correct materials, calculating proper V-openings, and performing regular maintenance will significantly improve product quality and tooling lifespan. Whether you operate a job shop or a high-volume CNC bending line, investing in the right tooling system is essential for consistency, speed, and long-term reliability.

Consider material, thickness, bend radius, and part geometry. Aluminum needs radius dies; stainless steel requires hardened tooling.

Single V, Multi-V, Acute (30°/45°), Radius, Hemming, and Offset dies.

Clean, lightly lubricate, store properly, check alignment, and sharpen carefully if needed.

No. Different metals need specific dies for best results and longer tool life.

Preencha as informações abaixo para receber um orçamento gratuito e uma brochura do produto. Responderemos dentro de 24 horas!