Sobre nós

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Project Overview

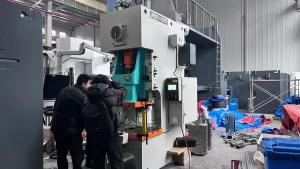

Durmapress has completed a large-scale shipment to one of Bulgaria’s leading steel fabrication groups, delivering a total of 17 units, consisting of:

- DP-Hybrid 300T4000 hydraulic press brakes

- Sheet follower systems

- Custom-designed press brake tooling sets

This Bulgarian client specializes in heavy steel structures and industrial equipment manufacturing, where large-format bending, high repeatability, and long-hour stability are essential. The new equipment will be integrated into their 2025 capacity expansion plan to support higher-volume production and multi-shift operations.

This shipment demonstrates Durmapress’s ability to curate complete bending solutions—including machines, auxiliary systems, and tooling—to support customers aiming for higher automation and reduced manual handling.

Equipment Configuration

Hydraulic Press Brakes – DP-Hybrid 300T4000 Series

The DP-Hybrid series represents a new generation of hybrid hydraulic press brakes, engineered for improved energy efficiency and consistent bending precision.

Key strengths include:

- A hybrid hydraulic drive that ensures smoother operation and reduced oil temperature rise

- A stable frame construction designed for long-term accuracy and minimal deflection

- CNC-controlled bending operations suitable for both simple and complex production tasks

- Enhanced responsiveness during multi-step bending sequences

These machines give the Bulgarian customer the reliability required for heavy-duty and thick-plate fabrication while maintaining clean bending lines and repeatable performance over long runs.

Sheet Follower Systems for Labor Reduction

To support large-format sheet handling, the customer opted for multiple sheet follower units, designed to:

- Reduce physical labor during bending of long or heavy sheets

- Improve positioning accuracy during repetitive operations

- Keep production stable across extended shifts

- Minimize the risk of workpiece deformation, slippage, or misalignment

Integrating sheet followers with hybrid press brakes allows operators to work faster and safer, enabling a semi-automated bending workflow without major changes to the shop layout.

Press Brake Tooling Sets – Custom Profiles

To ensure compatibility with diverse bending requirements, Durmapress supplied custom tooling sets, including upper punches and segmented dies.

These tooling sets support:

- Multiple bending radii and geometries

- High-durability performance for carbon steel and stainless steel

- Fast tool changes during high-mix production

- Improved edge finish and bending consistency

By providing machinery and tooling together, Durmapress guarantees a seamless setup that reduces downtime and accelerates the client’s transition to a more efficient production line.

Secure Packaging & Shipping Process

Given the scale of this 17-unit shipment, the logistics team implemented a multi-stage packaging sequence designed for long-distance European transit.

1. Full Machine Stabilization & Fastening

Each press brake and sheet follower was secured using:

Industrial steel cables

Pressure-tested anchor points

Non-slip base reinforcements

Ensuring zero movement during road, port, and sea transitions.

2. Layered Anti-Impact Protection

Components and sensitive zones were protected by:

High-density foam

Vibration-absorbing padding

Reinforced outer wrapping

Special care was applied to CNC modules and electrical housings.

3. Moisture & Corrosion Control

All machines were covered with:

Multi-layer anti-moisture film

Desiccant units in key compartments

Anti-rust protective coating on exposed metal

This ensures the equipment remains unaffected by humidity or temperature variations during long-duration storage or port handling.

4. Export Crate Reinforcement

Custom-built wooden crates were constructed for tooling and accessories, each designed to withstand heavy stacking and long-term pressure during transit.

Logistics Team Statement

“A 17-unit shipment requires discipline and precision at every stage.

Our team performs repeated load testing, fastening checks, and moisture inspections before sealing each crate.

Every machine must leave our facility fully protected—because our customers rely on us for zero-risk delivery.”

— Victor Zhang, Senior Logistics Manager, Durmapress

His statement reflects the company’s long-standing commitment to shipment safety and global delivery reliability.

Global Service Commitment

This delivery to Bulgaria adds to Durmapress’s expanding footprint across Europe, where manufacturers continue to adopt hybrid hydraulic bending technologies for improved productivity.

Durmapress remains committed to:

- Providing fully integrated bending solutions

- Ensuring consistent global delivery performance

- Supporting customers with installation guidance and after-sales service

- Offering flexible customization options for high-demand production lines

- With every shipment, Durmapress strengthens its role as a trusted partner in the global sheet-metal industry.