The Future of Metal Processing: Creating Efficient Production Lines with Numerical Control Punch Presses and Robotic Arms

- Conhecimento, Notícias

- 80+ reading now

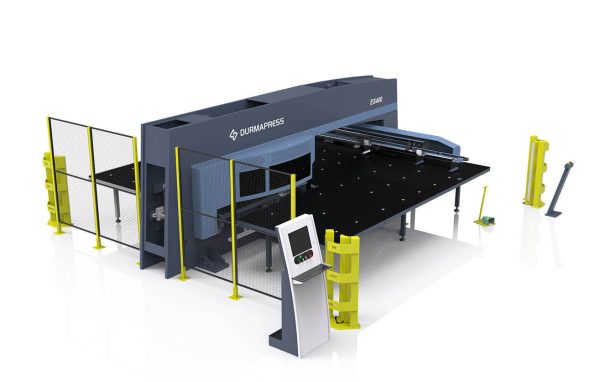

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

In traditional stamping production, manual material handling has significant drawbacks: low efficiency, high labor intensity, and numerous safety hazards. Workers have to repeatedly perform actions such as material retrieval, feeding, and unloading, which can lead to efficiency fluctuations and operational errors due to fatigue. Moreover, stamping operations themselves are highly hazardous, resulting in significant safety management pressure and long-term risk of work-related injuries, which directly affect production stability and personnel health.

With the advancement of "Industry 4.0," the demand for automated and intelligent equipment in manufacturing is becoming increasingly urgent. More and more enterprises realize that introducing automated equipment to achieve "machine replacement of human labor" is the key path to break through the bottleneck of traditional production models and enhance core competitiveness.

Tool Turret System

The core technology of the numerical control punch press lies in the tool turret system. This system consists of multiple tools, which are selected and replaced by robotic arms or mechanical arms to process sheets of various shapes and sizes. The tool turret system usually has four, six, or eight stations, and different stations can be equipped with different tools to meet various cutting requirements. The selection of materials and manufacturing processes for the turret system have a significant impact on the performance and reliability of the equipment.

Numerical Control System

The numerical control system of the numerical control punch press is a highly intelligent control system. It can automatically adjust process parameters according to user requirements, such as cutting speed, cutting depth, and cutting angle. The numerical control system also supports various programming methods, including manual programming, CAD/CAM automatic programming, and parametric programming. In addition, the numerical control system can achieve multiple functions, such as self-diagnosis, self-calibration, and automatic alarm, to improve the reliability and safety of the equipment.

Cutting System

The cutting system of the numerical control punch press is one of the core components of the equipment. The cutting system includes the cutting head, cutting tools, and fixtures. The cutting head is the main body of the cutting system, which controls the movement trajectory of the cutting tools. The cutting tools are the core components of the cutting system, and their quality directly affects the cutting effect and precision of the equipment. Fixtures usually use pneumatic or hydraulic clamping methods, which can achieve rapid and stable sheet processing.

Sistema de controlo

The control system of the numerical control punch press includes the numerical control system, servo system, hydraulic system, and pneumatic system. The control system can achieve automated operation and protection of the equipment, improving production efficiency and quality. The servo system is the main component that controls the movement of the equipment and can achieve high-precision motion control, improving the cutting precision and stability of the equipment. The hydraulic and pneumatic systems are mainly used for clamping and cutting control, which can achieve rapid and stable sheet processing.

Protection System

The protection system of the numerical control punch press is an important guarantee for the operation of the equipment. The protection system includes mechanical protection, electrical protection, and safety protection. Mechanical protection mainly includes overload protection, overheat protection, and cooling protection of the equipment. Electrical protection mainly includes leakage protection, overcurrent protection, and instantaneous voltage protection of the equipment. Safety protection mainly includes emergency stop protection and emergency shutdown protection of the equipment, which can ensure the safe operation of the equipment.

In summary, the technical highlights of the numerical control punch press mainly include the tool turret system, numerical control system, cutting system, control system, and protection system. The advantages and disadvantages of these technical highlights will directly affect the performance and reliability of the equipment. Therefore, we need to select high-quality numerical control punch press equipment and reliable suppliers to ensure the quality and stability of the equipment.

Protection System

The protection system of the numerical control punch press is an important guarantee for the operation of the equipment. The protection system includes mechanical protection, electrical protection, and safety protection. Mechanical protection mainly includes overload protection, overheat protection, and cooling protection of the equipment. Electrical protection mainly includes leakage protection, overcurrent protection, and instantaneous voltage protection of the equipment. Safety protection mainly includes emergency stop protection and emergency shutdown protection of the equipment, which can ensure the safe operation of the equipment.

In summary, the technical highlights of the numerical control punch press mainly include the tool turret system, numerical control system, cutting system, control system, and protection system. The advantages and disadvantages of these technical highlights will directly affect the performance and reliability of the equipment. Therefore, we need to select high-quality numerical control punch press equipment and reliable suppliers to ensure the quality and stability of the equipment.

In the material handling process, robots are used to replace manual operations, and vision systems are employed to inspect products, effectively avoiding idle labor and resource waste, and significantly reducing employee labor intensity.

The numerical control punch press, combined with a robotic arm in an automated production line, can achieve automated material handling. Relying on the multi-degree-of-freedom flexible motion characteristics of the robotic arm (such as vertical lifting, horizontal movement, and rotational flipping), it can precisely match the production rhythm of sheet metal processing by the numerical control punch press, achieving full-process automated operations. The entire process, from material handling to stamping, can be seamlessly connected without human intervention.

It also supports quick parameter presetting through the human-machine interface, allowing efficient switching of production programs for different parts in a short time. Whether for simple or complex sheet metal processing, it can achieve "unmanned" continuous production and flexible adaptation.

The numerical control punch press, with its advanced numerical control system and stable mechanical structure, forms an efficient collaboration with the automated robotic arm. The robotic arm has multi-degree-of-freedom movements and can automatically adapt to the height of the punch press, feeding height, and unloading height. Once the parameters are adjusted, the entire process, from precise material retrieval to feeding into the punch press mold for processing, and then to the final unloading, can be completed without human intervention. This truly realizes "unmanned" automated production, significantly reducing the time loss and error rate of manual operations.

In terms of production cost control and product quality improvement, automated production plays a key role.

From a cost control perspective, automation reduces reliance on human labor. In the past, workers had to manually handle material feeding and unloading beside the punch press, which was labor-intensive and inefficient. Now, workers can operate through monitoring systems and operation terminals, reducing labor intensity and safety risks, and lowering labor costs.

In terms of product quality improvement and comprehensive cost control, automation brings a leap in production efficiency. The production time per unit is significantly shortened, and equipment utilization is greatly improved. Raw material waste is precisely controlled. At the same time, advanced automated production processes significantly enhance the stability of product quality, reducing the rate of defective products and avoiding additional costs caused by rework due to defects. Through effective cost control and steady quality improvement, enterprises can gain greater economic advantages in market competition.

As a high-precision metal processing equipment, the numerical control punch press is widely used in various industries. The following are some industries that require the use of numerical control punch presses:

Automotive Manufacturing: The automotive industry requires a large number of metal parts, such as body panels, doors, and chassis. The numerical control punch press can efficiently process various complex-shaped metal sheets, meeting the automotive industry's demand for high-precision and high-efficiency processing, and improving production efficiency and product quality.

Electronics Manufacturing: Electronic products usually require very precise metal casings and parts. The numerical control punch press can accurately process small holes and complex structures, meeting the high-precision processing requirements of electronic products, such as smartphones, tablets, and televisions.

Telecommunications Equipment Manufacturing: Telecommunications equipment requires a large number of metal brackets, casings, and connectors, which usually need high-precision processing. The numerical control punch press can meet the telecommunications equipment manufacturing industry's demand for complex structures and high-precision processing.

Mechanical Manufacturing: The numerical control punch press can process various mechanical equipment parts, such as gears, bearing housings, and connecting plates. For the mechanical manufacturing industry, the numerical control punch press can improve processing efficiency and product quality, and reduce production costs.

Medical Device Manufacturing: Medical devices usually require high-precision metal parts, such as surgical instruments and medical devices. The numerical control punch press can meet the medical device manufacturing industry's demand for high-precision and high-reliability products.

Appliance Manufacturing: The appliance manufacturing industry requires a large number of metal parts, such as washing machine drums, refrigerator casings, and air conditioner radiators. The numerical control punch press can meet the appliance manufacturing industry's demand for high-precision, high-efficiency, and diversified products.

In summary, the numerical control punch press plays an important role in various industries and can meet the processing needs of high-precision, high-efficiency, and diversified products. With the continuous development of manufacturing and technological progress, the numerical control punch press will play an important role in more fields and become an important production tool in manufacturing.

With the continuous development of technologies such as artificial intelligence and the Internet of Things, the automation level of stamping production will reach new heights. In the future, through deep integration with the industrial internet platform, stamping production will definitely achieve real-time monitoring of equipment status and intelligent analysis of production data, moving towards more efficient, flexible, and intelligent directions, and continuously empowering the high-quality development of manufacturing. In today's increasingly competitive manufacturing industry, automation upgrade is no longer a "multiple-choice question," but a "compulsory question." Choosing the right automation solution is choosing the future competitiveness of the enterprise.

Preencha as informações abaixo para receber um orçamento gratuito e uma brochura do produto. Responderemos dentro de 24 horas!