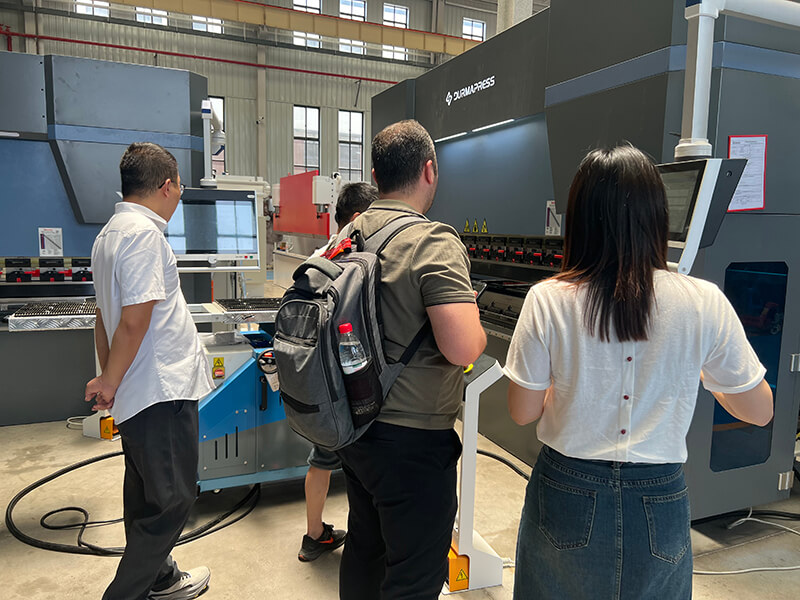

Last week, Durmapress hosted an exclusive factory visit for industrial customers from Turkey and Syria, who visited our facility for a comprehensive tour and technical inspection. The visit focused on our latest sheet metal processing technologies, with particular interest in the DP-ES 250T3200 DA53TX press brake and 30x3200 guillotine shearing machine with floor-standing full follow-up support system.

Why the DP-ES 250T3200 DA53TX Press Brake Impresses Customers Worldwide

Combining 250 tons of force with a 3200 mm bend length, the DP-ES 250T3200 DA53TX press brake is ideal for high-volume production of aerospace and automotive parts. Customers witnessed the ±0.01 mm repeatability and automatic crown compensation achieved by its DA53TX CNC system, which is essential for complex bends of stainless steel and aluminum. The integrated floor-standing follow-up support system enhances stability for high-precision operations and reduces the risk of material deformation.

In addition, the 30x3200 guillotine shearing machine demonstrated how to quickly cut 30 mm thick steel plates with laser-guided precision. Its hydraulic synchronization and quick tool change system (less than 5 minutes) meet customer needs for agile, high-volume production.

Behind the Scenes: Smart Manufacturing Innovation

During the tour, customers visited Durmapress’ ISO-certified assembly line, where the DP-ES 250T3200 DA53TX press brake is manufactured using premium components such as Schneider Electric systems and Delem CNC control systems. Quality assurance protocols including 72-hour pressure testing and laser calibration ensure its durability in the harsh industrial environments of Turkey and Syria.

Customer Feedback: Meeting Regional Industrial Needs

The Turkish machinery distributor stressed: “The servo-hydraulic system of the DP-ES 250T3200 press brake reduces energy costs by 30%, which is critical in our cost-sensitive market.”

The Syrian OEM representative added: “The speed of the guillotine shearing machine and the smart die management have reduced setup time by 80%, increasing the output of our workshop.”

After the factory acceptance, the customer expressed satisfaction with the quality and performance of our equipment and shared the positive feedback with our sales team. We look forward to establishing long-term partnerships with our customers and continuously creating value through advanced press brake and shearing solutions.

Contactar-nos

Publicações recentes

Siga-nos

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.