A equipa de pós-venda da Durmapress comissiona com sucesso o novo equipamento para a filial filipina de um cliente alemão!

The Durmapress after-sales engineering team performed a quick-response commissioning mission at the German industrial group’s Philippine subsidiary, perfectly setting up the DP-ES GENIUS CNC 135T3200 DA69S 11+1 axis press brake and BS4020H-20KW fiber laser cutting machine in just 0.5 working days, setting a new benchmark for global service efficiency.

Task breakdown: Precision pressure

Location: Cavite Export Processing Zone, Philippines

Timeline:

08:00am: Equipment unpacking and power supply integration

10:30am: DP-ES GENIUS 135T3200 press brake calibration (±0.01mm repeatability verified)

12:00pm: BS4020H-20KW fiber laser cutting machine test cutting on 15mm stainless steel (edge burr-free confirmed)

01:30pm: Full production trial on a customer automotive chassis component

Why these machines need expert commissioning

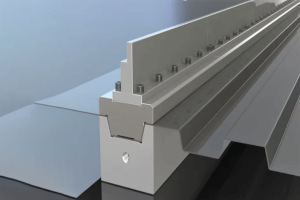

- DP-ES GENIUS 135T3200 DA69S press brake

11+1 axis control (Y1/Y2/X/R/Z1/Z2/V1/V2) for bending of aviation-grade titanium alloys

AI-assisted collision avoidance system

Moisture-resistant servo drive for tropical environments

- BS4020H-20KW fiber laser cutting machine

4000×2000mm working area with 20kW fiber source

Accuracy up to ±0.03mm/m at 40°C ambient temperature

Automatic nozzle changer for mixed thickness processing

Customer verification: Perfect combination of German precision and Durmapress speed

Plant manager confirmed:

“The burr-free edge of the BS4020H fiber laser cutting machine does not require manual grinding after cutting like other equipment we purchased, saving $120 in secondary processing costs per day. Your team’s pre-commissioning virtual simulation can complete the actual setup in 3.5 hours. The 11+1 axis bending machine bent 8mm with an angle consistency of 0.15° thick aluminum, while a 20 kW laser cut 25 mm carbon steel at 1.2 m/min—both out of spec. This efficiency saved us $46,000 in lost production time.”

Key Comparison: Why Cheap Alternatives Fail

Customers share painful lessons learned from previous “cheap” equipment purchases:

“Our previous press brake from a low-cost supplier developed chronic oil leaks within 6 months due to substandard seals. Its welded frame prevented hydraulic compensation upgrades, and when the CNC failed, there were no repair options—not even a schematic! We were stuck in a dead end: no maintenance, no upgrades, only scrap and replace. In contrast, Durmapress’s modular design allows us to replace DA69S modules or upgrade axes in a matter of hours.”

Durmapress prides itself on providing a fast and reliable commissioning process. Our experienced engineers completed all setup and testing of the press brake and fiber laser cutting machine in just half a day, ensuring that customers can resume production with minimal downtime. The team also provides hands-on training and operating instructions to local employees, enabling them to operate the new machines efficiently and safely.

Sobre nós

A Durmapress é especializada na conceção, fabrico e venda de vários equipamentos de processamento de metal, incluindo máquinas de dobragem, tesouras, punções, máquinas de corte a laser, etc. A empresa foi fundada em 2000. Com anos de experiência e acumulação de tecnologia. DurmaPress tornou-se uma das marcas bem conhecidas na indústria de máquinas de processamento de metal da China.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.