Press Brake Manufacturing: Full Process, Key Components & How Modern Machines Are Built

- Conhecimento, Notícias

- 90+ reading now

Discover how press brakes are manufactured—from frame welding to CNC control integration. Learn key components, modern technologies, and what affects machine quality.

The global demand for high-precision sheet-metal fabrication continues to rise, and manufacturers increasingly rely on advanced press brakes to deliver consistent bending accuracy, faster production cycles, and lower operational costs. But few fabricators truly understand how a press brake is made, what components influence performance, or how modern manufacturing ensures repeatable accuracy.

This guide reveals the complete press brake manufacturing process, the critical components, and how modern CNC and servo technologies elevate machine performance.

Press brake manufacturing refers to the engineering, fabrication, assembly, and quality-control processes involved in building a fully functional bending machine. These steps ensure the press brake achieves:

→ You may also explore our CNC Press Brake solutions for high-precision bending.

Modern press brake production typically includes eight major stages. Each stage influences machine accuracy, reliability, and lifespan.

The frame is the backbone of every press brake. Durmapress uses heavy-duty steel plates, laser-cut and CNC-machined, then welded by certified technicians.

Key steps include:

A stress-relieved frame prevents deformation over years of bending operations.

After stress relief, the frame undergoes gantry milling to ensure perfect parallelism between the table and ram.Critical tolerances include:

This step directly impacts bending precision and machine lifespan.

The hydraulic system controls ram movement. High-quality press brakes typically use:

Hydraulic calibration ensures:

Modern machines include advanced components from:

Proper cable routing and electrical cabinet cooling are crucial for reliability.

This is where the machine becomes “smart.”

Common CNC systems include:

→View our full range of Sheet Metal Bending Machines for different production requirements.

The CNC system manages:

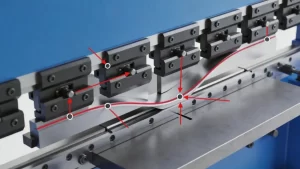

The backgauge ensures repeatable bending.High-end machines use ball screws, linear guides, and servo motors for micron-level positioning.

Common structures:

| Backgauge Type | Axes | Application |

|---|---|---|

| Eixo X | 1 | Basic bending tasks |

| X + R | 2 | Standard industry use |

| X + R + Z1 + Z2 | 4 | High-mix sheet-metal fabrication |

| 6-axis backgauge | 6 | Complex multi-step productions |

This step includes:

→Learn more about our Ferramentas de prensagem options for different bending applications.

Before delivery, every modern press brake undergoes:

Only after passing all testing does the machine enter packaging and shipping.

Modern press brakes rely on many precision components. Below are the most influential parts.

Modern press brakes rely on many precision components. Below are the most influential parts.

Servo hybrid technology is becoming the preferred choice thanks to:

→Discover our Servo Hybrid Press Brake series for energy-efficient bending.

The CNC system determines the ease of programming and bending simulation accuracy.

Includes punches, dies, hemming tools, radius tools, and custom profiles.

Ensures accurate positioning for every bend.

Essential for CE/ISO compliance.

Press brakes are used across industries:

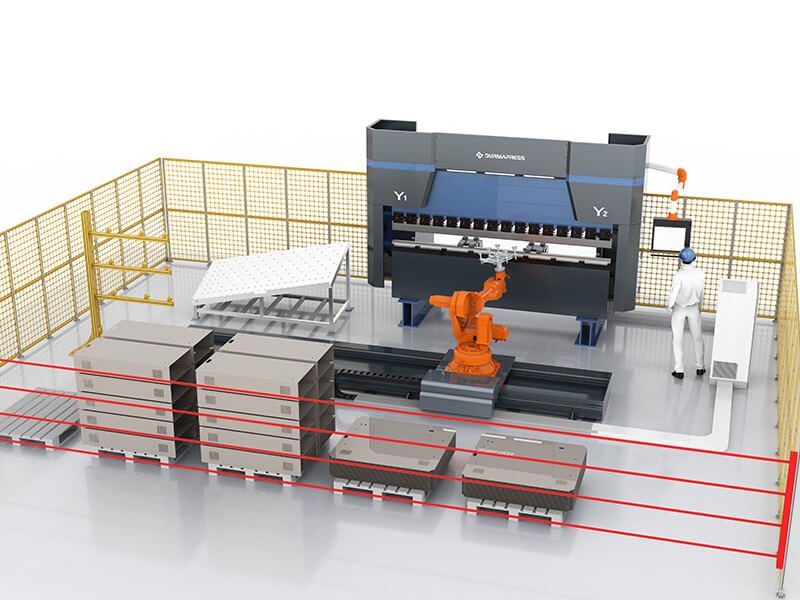

→Explore how a Robotic Press Brake System improves productivity in high-volume automation.

Modern factories are adopting:

These innovations significantly reduce labor costs and improve consistency.

| Manufacturing Stage | What Happens | Impact on Quality |

|---|---|---|

| Frame welding & stress relief | Builds the main structure | Stability & durability |

| Gantry milling | Precision machining | Bending accuracy |

| Hydraulic assembly | Pump, valves, piping | Smooth motion |

| CNC installation | Software intelligence | Automation level |

| Backgauge assembly | Positioning system | Repeatability |

| Tooling & crowning | Punch/die setup | Angle accuracy |

| Final testing | Calibration & bending tests | Overall performance |

Typically 20–45 days depending on size, CNC system, customization, and tooling requirements.

Main factors include frame rigidity, CNC synchronization, hydraulic stability, and the type of tooling used.

Hydraulic is durable; hybrid is efficient and stable; servo-electric is ideal for thin materials and high-speed applications.

CE certification, ISO9001, and in some regions, UL compliance for electrical safety.

Yes. Many factories integrate robotic loading/unloading with a robotic press brake cell.

Preencha as informações abaixo para receber um orçamento gratuito e uma brochura do produto. Responderemos dentro de 24 horas!