Sobre nós

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Project Overview

Durmapress recently completed a high-precision shipment to a long-standing manufacturing client in Canada, dispatching two EP18-800 press brake machines to support their expansion in custom metal fabrication. The customer required equipment capable of maintaining repeatable accuracy across mixed-batch production—particularly for automotive components and structural steel parts.

The EP18-800 press brake series was selected after a detailed engineering consultation, ensuring that its combination of CNC intelligence, hydraulic stability, and robust frame integrity matched the client’s operational requirements. This shipment demonstrates Durmapress’s commitment to delivering tailored solutions for global industrial partners.

Performance Advantages

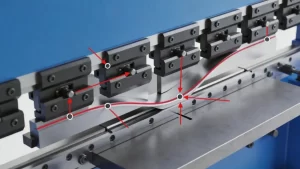

The EP18-800 brings several capabilities essential to the customer’s workflow:

- Consistent bending accuracy supported by CNC real-time compensation

- Reduced operator adjustments through automated setup programs

- Fast cycle times due to high-speed ram approach and return

- Superior repeatability for small-batch or high-mix production cycles

- Durable hydraulic press brake architecture designed for continuous operation

- Collaborative Efficiency for the Customer’s Workshop

Although compact in footprint, the two units operate in parallel lines to handle bending tasks of different thicknesses and lengths without frequent tool changes. This layout helps the Canadian manufacturer:

- Shorten production transitions

- Improve throughput during peak demand

- Maintain bending consistency across multi-shift operations

The dual-machine configuration allows the press brake machines to complement each other, enabling seamless integration within a high-precision fabrication facility.

Secure Packaging & Shipping Process

For this shipment, the logistics team executed a multi-layer protection strategy tailored for long-distance transport from China to Canada.

- Industrial-Grade Packaging Measures

- Full-machine film wrapping to block moisture and airborne dust

- High-density corner protectors around the frame and hydraulic cabinet

- Anti-scratch protective pads applied at all contact points

- Custom-built wooden crates compliant with international fumigation standards

- Structural Securing for Ocean Transport

- Inside the container, both press brakes were reinforced using:

- Marine-grade steel cables connecting key frame sections to the floor

- Heavy locking plates and welded anchor points to prevent lateral movement

- Shock-absorption pads placed under the machine base

- Humidity-control desiccant packs to safeguard hydraulic and CNC electronics

These protective measures ensure that each CNC press brake arrives exactly as it left the workshop—manufactured clean, calibrated, and production-ready.

Logistics Team Statement

“Every shipment is a responsibility we take personally. For heavy equipment like the EP18-800 press brake, our priority is to ensure absolute stability during transport—from the first round of inspection to final sealing of the container. Our team verifies every securing point twice before release, because customers rely on us not only for machines, but for confidence.”

— Michael Zhang, Senior Logistics Manager, Durmapress

The delivery of two EP18-800 CNC press brake machines to Canada highlights Durmapress’s expanding global logistics network and our ability to support customers with installation guidance, tooling consultation, and long-term technical service.

With dedicated service teams and strategic partners worldwide, we ensure that each hydraulic press brake or brake machine shipped is backed by reliable after-sales support. Our mission remains consistent: empower manufacturers with stable, intelligent, and efficiently delivered forming solutions.