Industry 4.0 And Smart Manufacturing: The Transformative Power Ushering In A New Era Of Industry

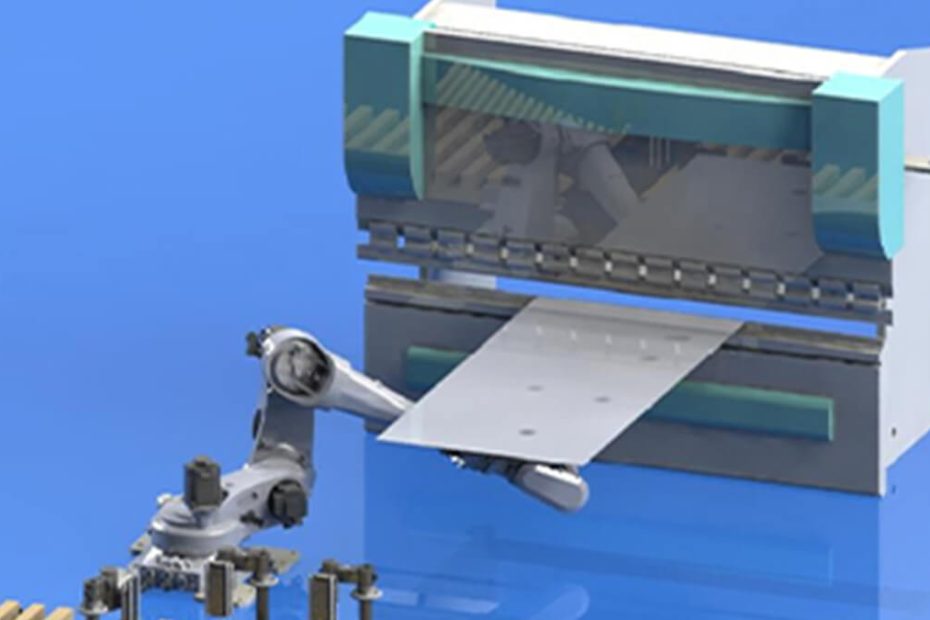

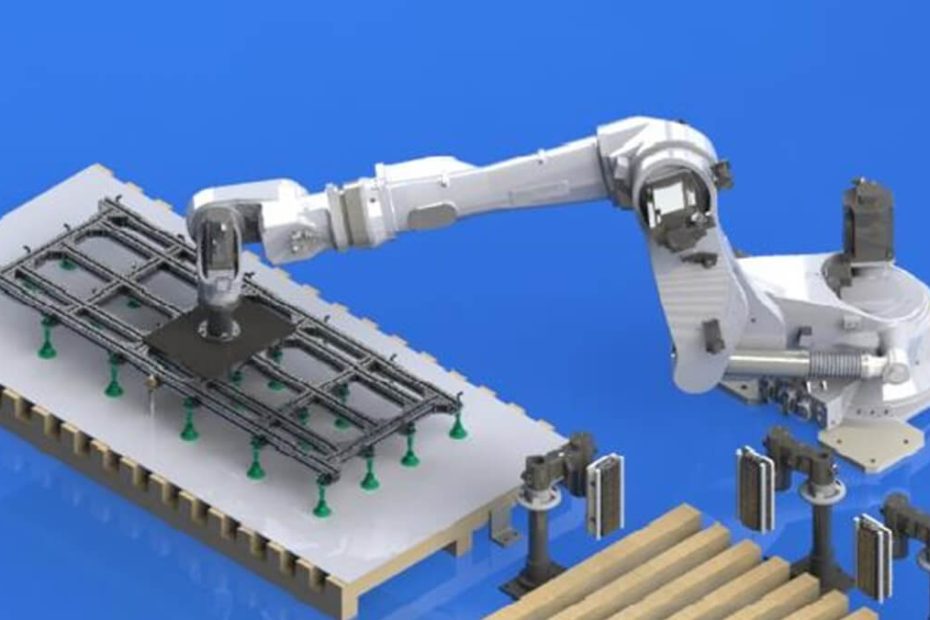

When the robotic arms in traditional factories start to independently perceive production rhythms, and when supply chains can predict market fluctuations through data, the industrial sector is undergoing a profound transformation driven by Industry 4.0 and smart manufacturing. This transformation is not just an iteration of technologies, but a comprehensive reshaping of production paradigms, business models, and even industrial ecosystems. Smart Manufacturing and Industry 4.0 The concept of smart manufacturing originated in the late 1980s. Professor P.K. Wright from New… Ler mais "Industry 4.0 And Smart Manufacturing: The Transformative Power Ushering In A New Era Of Industry

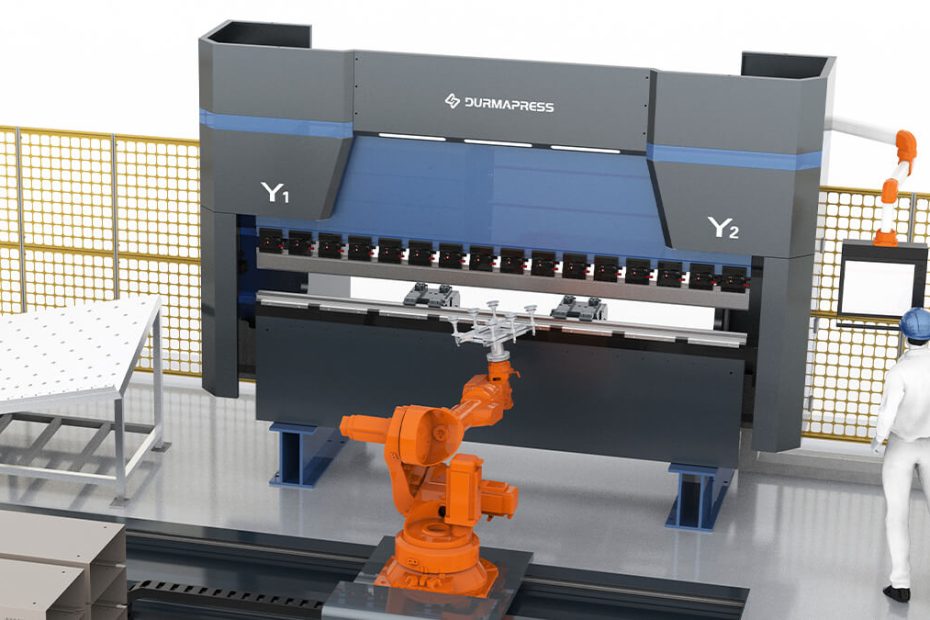

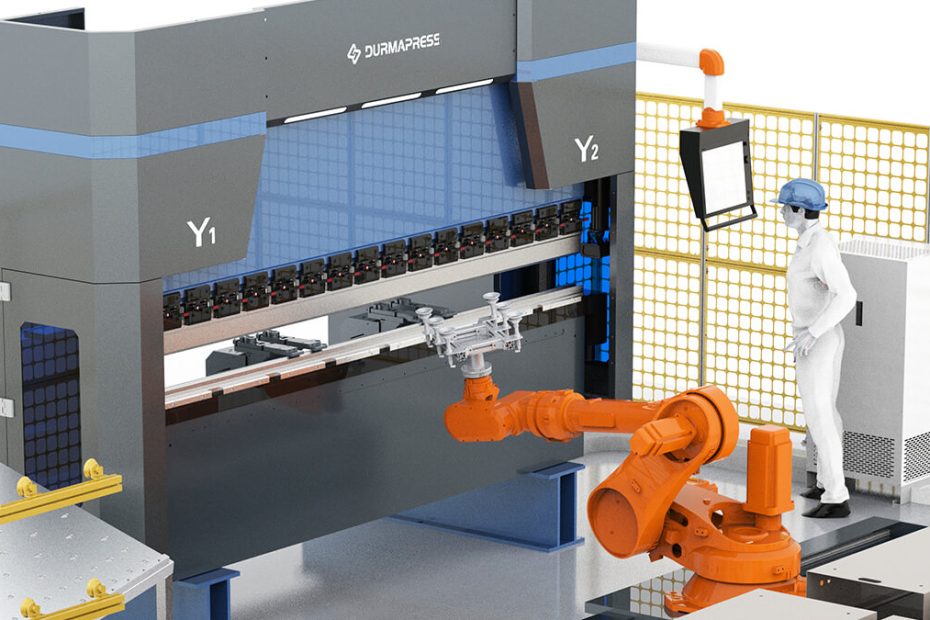

-930x620.jpg)

How-Can-The-MES-System-Eliminate-Inefficiency-In-Automotive-Sheet-Metal-Manufacturing-930x620.jpg)