Máquina de ranhurar vertical em V

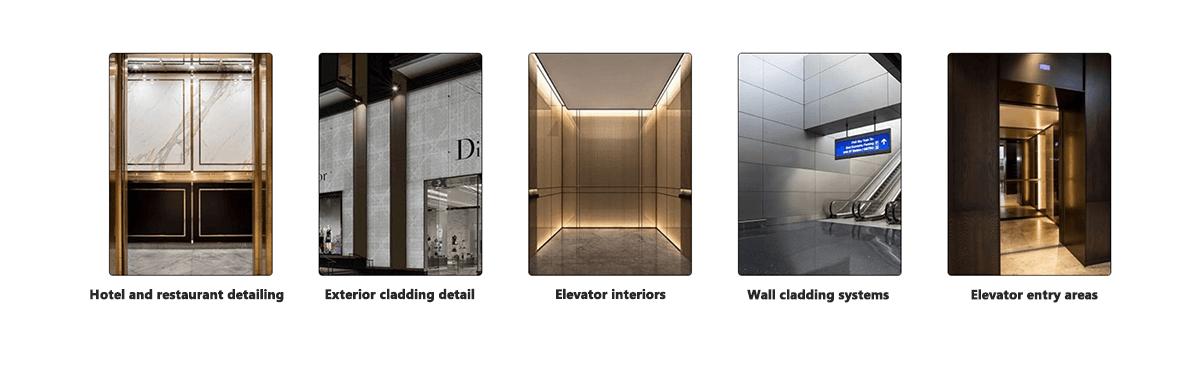

Discover high-precision Vertical V Groover Machines for stainless steel, aluminum, and metal panels. Ideal for decorative grooving with clean, sharp angles.

Discover high-precision Vertical V Groover Machines for stainless steel, aluminum, and metal panels. Ideal for decorative grooving with clean, sharp angles.

Personalize a sua configuração de acordo com as suas necessidades

Standard accessories for V Groover Machine

A rigid, high-strength structure that ensures stability, minimizes vibration, and supports precise grooving performance during operation.

A protective enclosure located at the back of the machine, designed to shield internal components, enhance safety, and provide a clean, organized appearance.

An intuitive interface that allows operators to set parameters and monitor the grooving process with precision and ease.

A positioning system that accurately sets the metal sheet's location for precise and consistent grooving operations.

Blades for CNC V Grooving Machines is essential for optimizing performance, ensuring precision, and maintaining the durability of both the machine and the blades.

It ensures high precision by preventing the movement or shifting of the workpiece. The clamp is adjustable to accommodate various sheet thicknesses and is essential for safety, accuracy, and efficiency

A Durmapress segue sempre o conceito de colocar os clientes em primeiro lugar em toda a experiência de compra, e optimiza e inova continuamente o processo de produção para satisfazer as necessidades de todas as grandes, médias e pequenas empresas de produção.

1

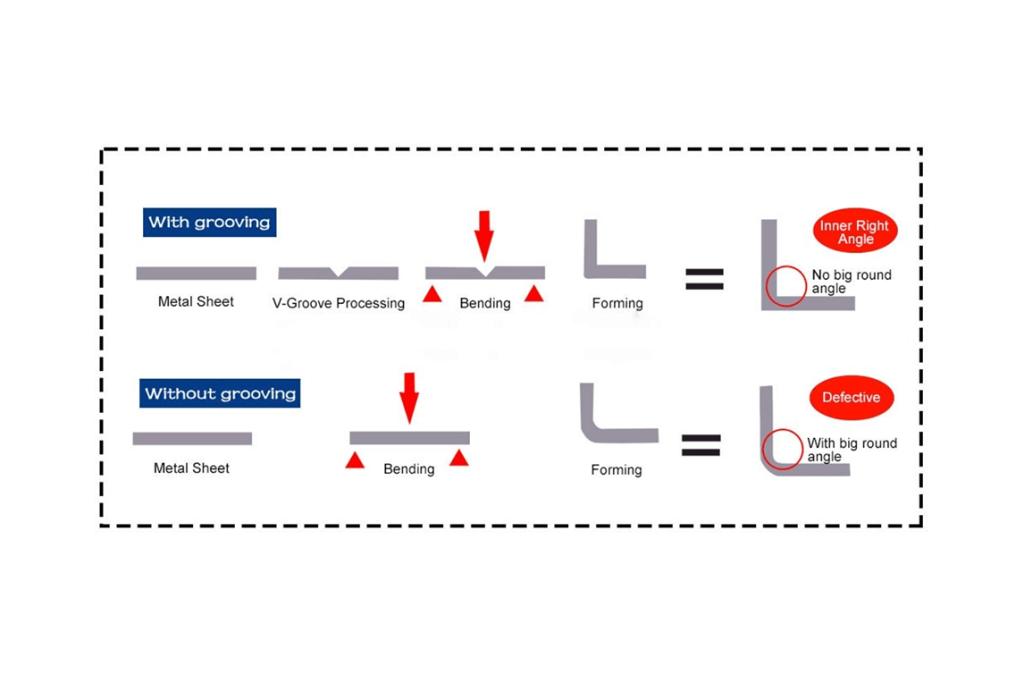

CNC V Grooving Machines are known for their exceptional precision, ensuring accurate grooves and cuts. The computer-controlled system allows for exact measurements and consistent results, minimizing errors and material waste.

2

These machines can handle a wide range of materials, including stainless steel, aluminum, copper, and other metals. They are versatile enough to be used in various industries such as aerospace, automotive, architecture, and electronics.

3

CNC technology automates the grooving process, significantly reducing manual labor and increasing productivity. The machines can operate continuously with minimal supervision, leading to faster turnaround times and higher output.

4

The precision of CNC V Grooving Machines means that material waste is minimized. The exact cutting and grooving reduce the likelihood of errors that could lead to costly rework or material loss.

5

CNC machines are designed with safety features that protect operators from potential hazards. Automated processes reduce the need for manual handling of materials, lowering the risk of accidents and injuries.

6

With CNC V Grooving Machines, creating complex and intricate designs becomes much easier. The advanced software allows for detailed programming, enabling the production of sophisticated patterns and shapes that would be difficult to achieve manually.

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

7/24

Preencha as informações abaixo para receber um orçamento gratuito e uma brochura do produto. Responderemos dentro de 24 horas!