1 Resumen.....................................................................................................................................3

1.1 Programación/ejecución............................................................................................................3

1.2 Más programación................................................................................................................3

1.3 Parámetros avanzados............................................................................................................. 4

1.4 Selección de modo.......................................................................................................................5

1.5 Parámetro del sistema...................................................................................................................6

1.6 Diagnóstico a máquina................................................................................................................. 6

2.Sistema de depuración................................................................................................................7

2.1 Configuración de las válvulas.......................................................................................................................... 7

2,2 Coeficiente.............................................................................................................................. 8

2.2.1 Eje X....................................................................................................................................8

2.2.2 Eje Y................................................................................................................................... 8

2.3 Depuración de ángulos.................................................................................................................... 9

2.3.1 Molde superior..........................................................................................................................9

2.3.2 Molde inferior..........................................................................................................................9

2.3.3 Otro parámetro.................................................................................................................10

2.4 Calibración angular.................................................................................................................. 10

2.5 Longitud de la calibración.............................................................................................................11

2.6 Resistencia del bastidor......................................................................................................................12

2,7 Regla de rejilla.............................................................................................................................. 12

2.8 Compensación mecánica................................................................................................... 13

2,9 Gran arc............................................................................................................................... 13

2.10 Eje Y1-Y2.............................................................................................................................14

3.Funcionamiento del usuario.....................................................................................................................14

3.1 Programación de un solo paso..................................................................................................... 14

3.2 Programación en varios pasos......................................................................................................15

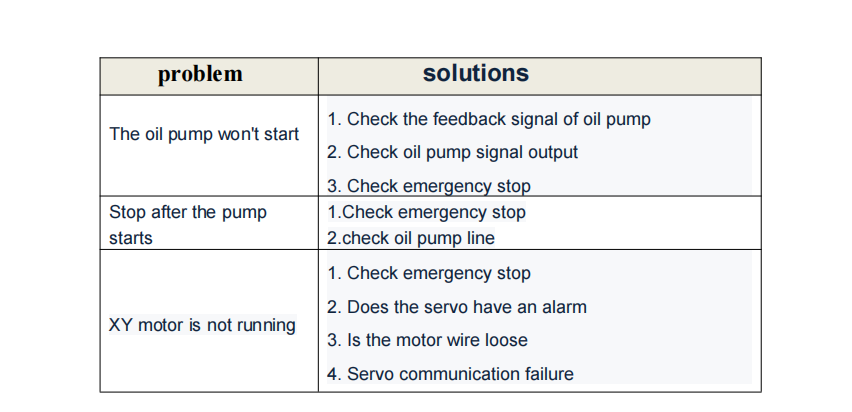

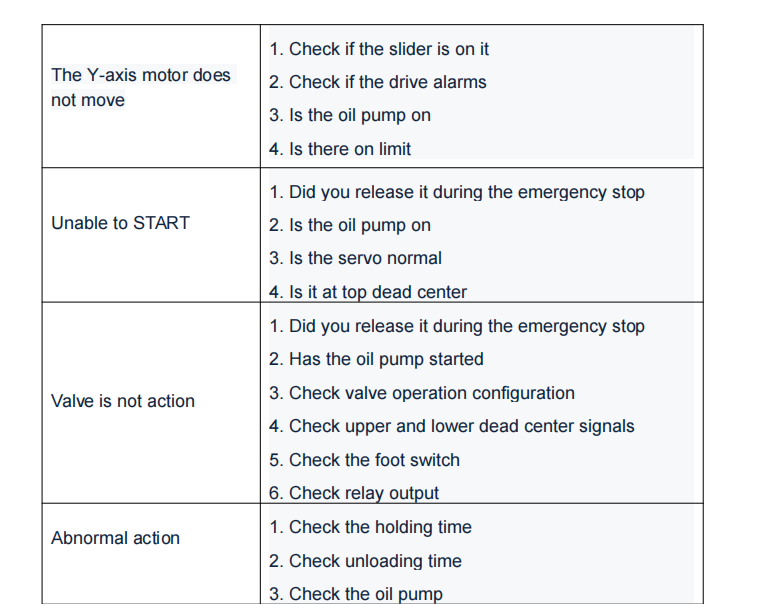

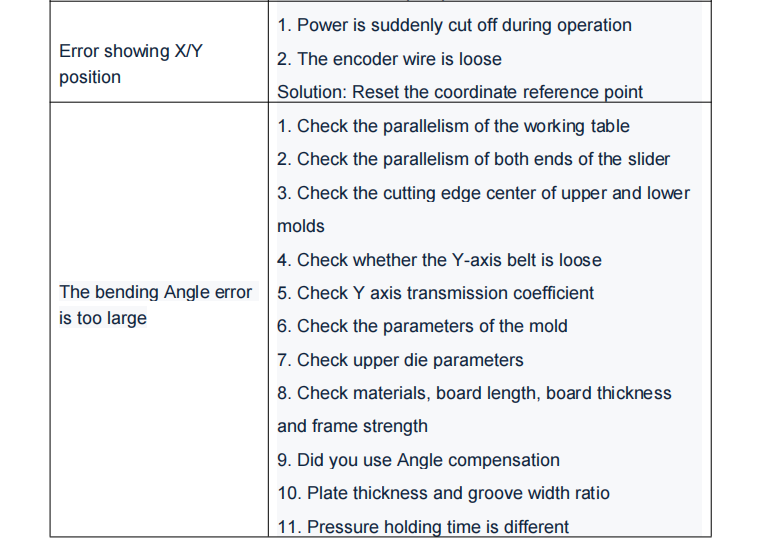

4.Problema común...............................................................................................................15

Directory:

1 overview.....................................................................................................................................3

1.1 programming/running............................................................................................................3

1.2 more programming................................................................................................................3

1.3 advanced parameters............................................................................................................. 4

1.4 mode selection.......................................................................................................................5

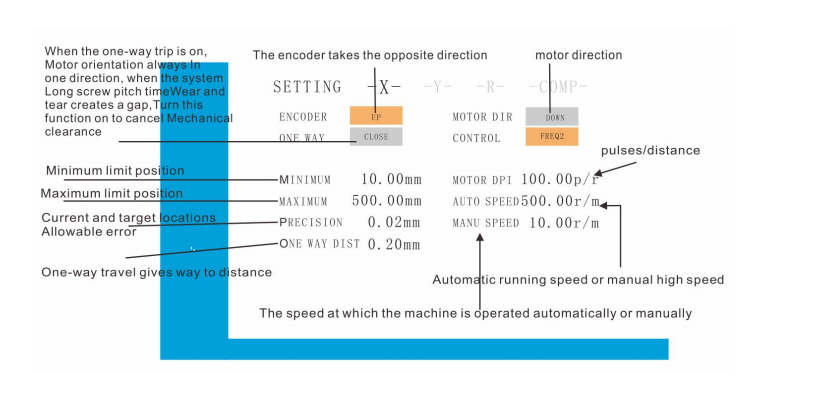

1.5 system parameter...................................................................................................................6

1.6 machine diagnosis................................................................................................................. 6

Directory:

1 overview.....................................................................................................................................3

1.1 programming/running............................................................................................................3

1.2 more programming................................................................................................................3

1.3 advanced parameters............................................................................................................. 4

1.4 mode selection.......................................................................................................................5

1.5 system parameter...................................................................................................................6

1.6 machine diagnosis................................................................................................................. 6

- debugging system................................................................................................................7

- user operation.....................................................................................................................14

- common problem...............................................................................................................15

1 resumen

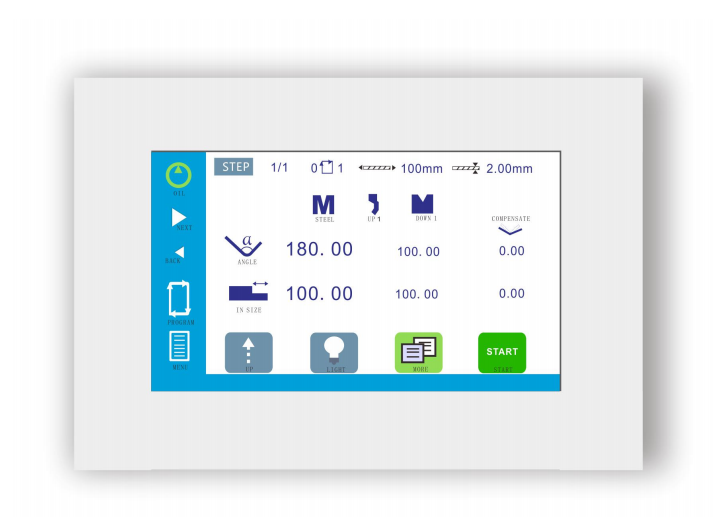

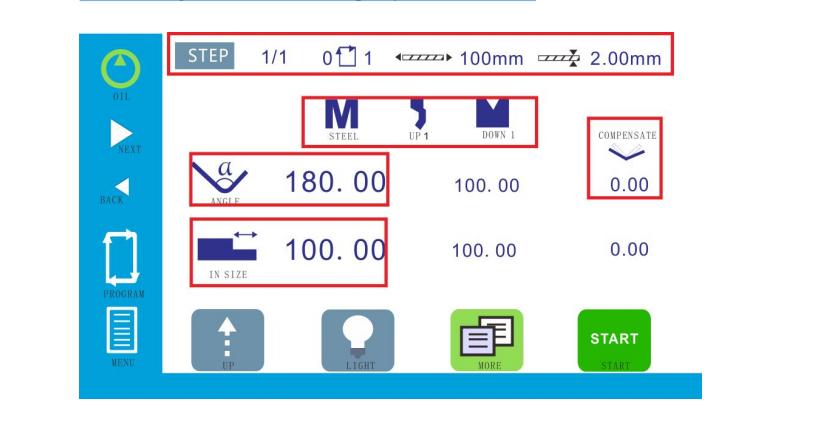

1.1 programming/running

1.2 Más programación

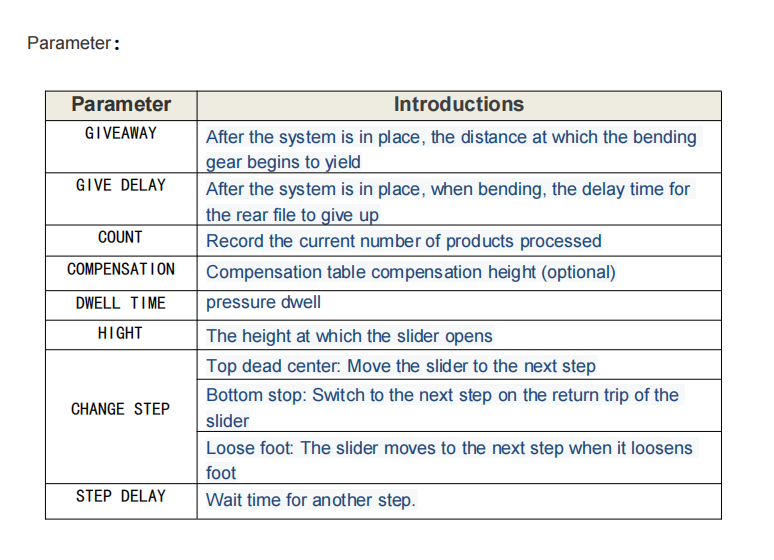

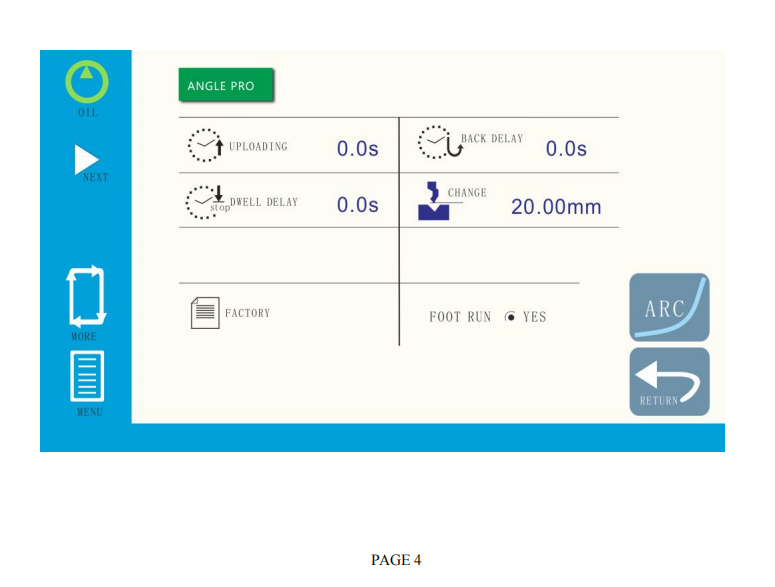

1.3 parámetros avanzados

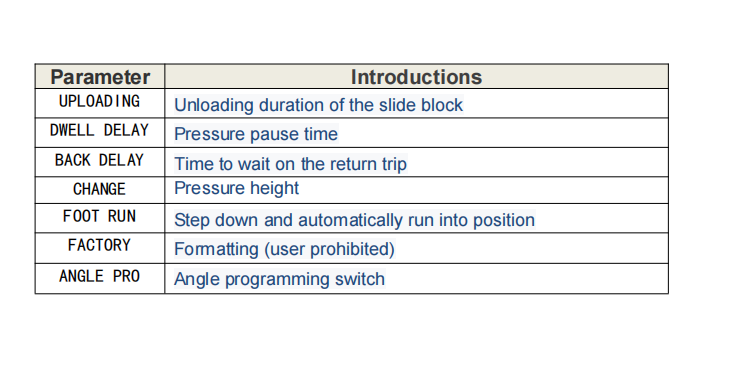

1.4 mode selection

Inching: Inching controlSingle: Automatic return after the end of a single bendContinuous: Automatic cycle operation

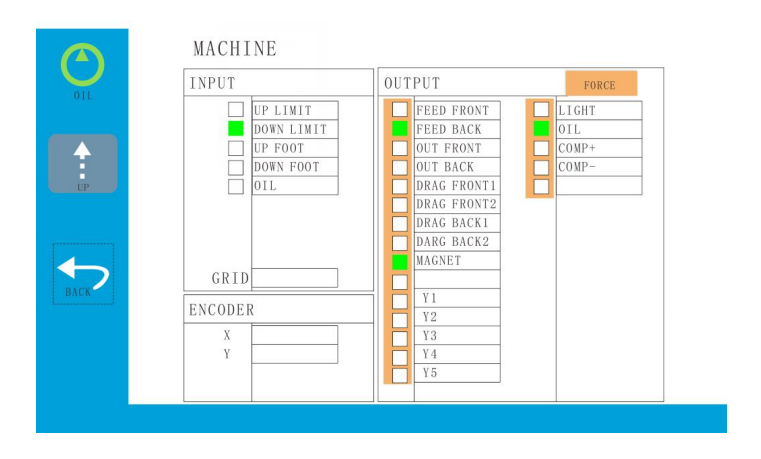

1.6 machine diagnosis

- Machine state allows you to view all the state of the machine:

2.debugging system

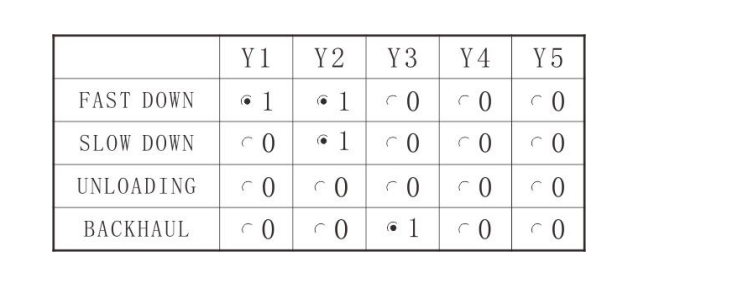

When the system is used for the first time, it is necessary to debug the machine to achieve the purpose of users. Para depurar es necesario realizar los siguientes pasos.2.1 ajuste de las válvulas

Baja: Baja. Desaceleración: Acción de presión. Descarga: Acción de descarga. Backhaul: Acción de retroceso.

2.2 coefficient

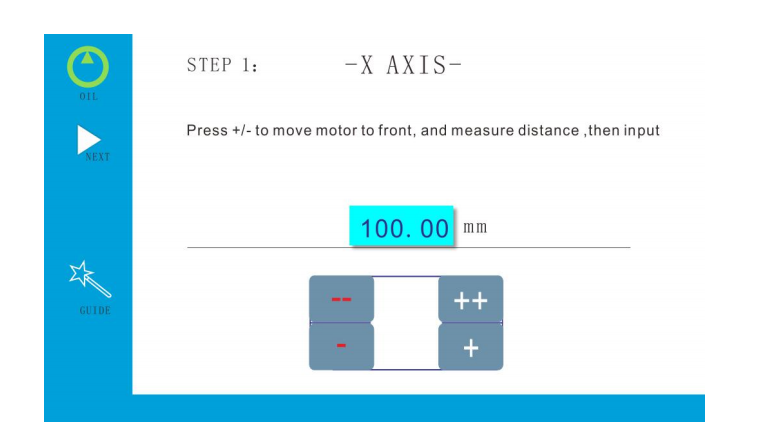

2.2.1 Eje XSiguiendo los pasos anteriores, ya está listo para ajustar el ángulo de curvatura.

2.3 angle debugging

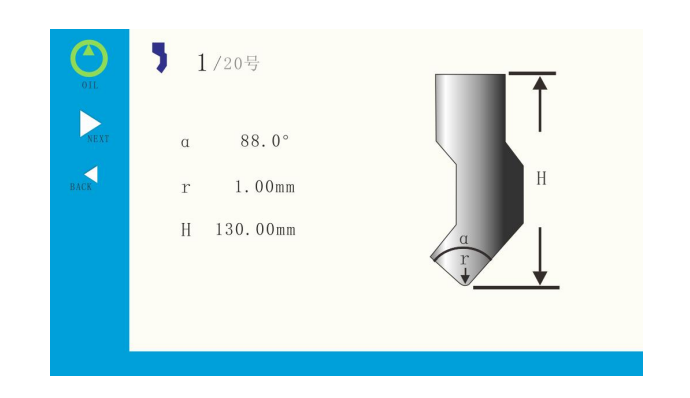

En primer lugar, fijamos los tamaños superior e inferior del molde:2.3.1 molde superior

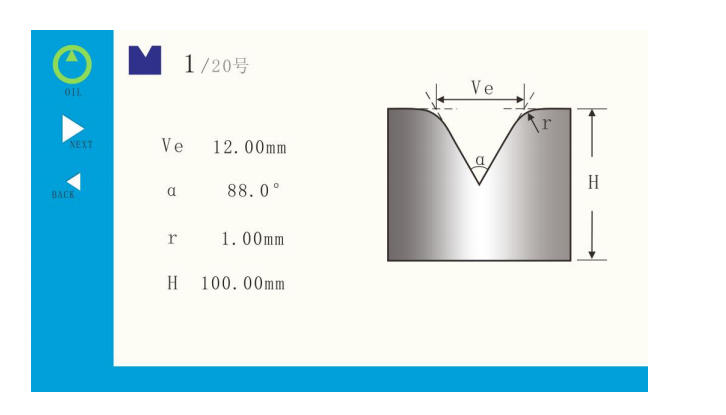

2.3.2 molde inferior

2.3.3 otro parámetro

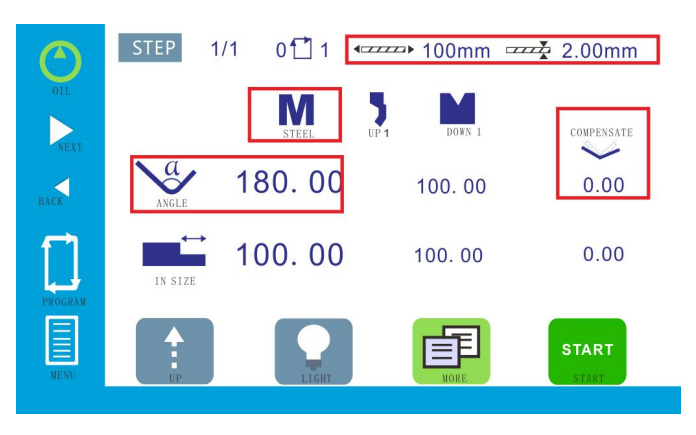

La siguiente caja roja:2.4 angle calibration

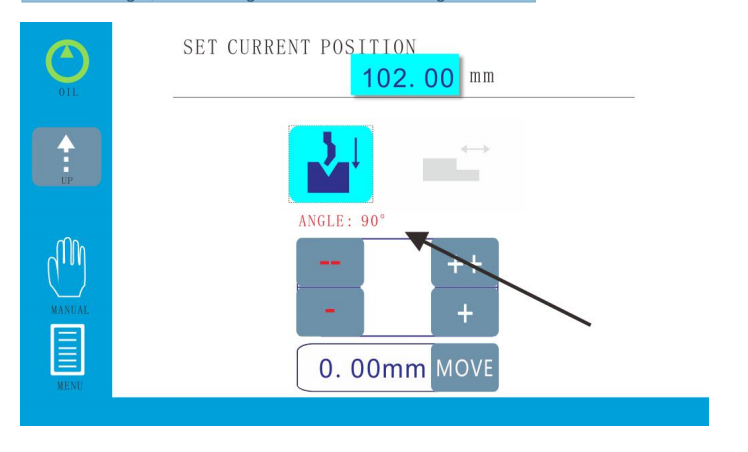

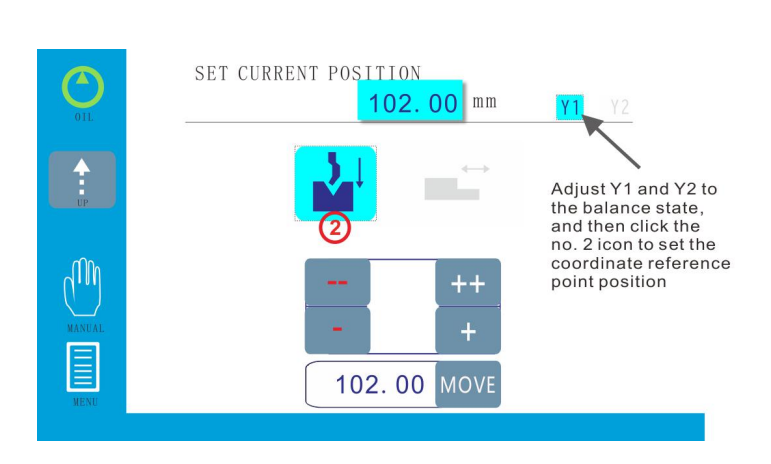

Set up the upper mold, lower mold, material, plate thickness and plate length, click the menu and enter manual debugging. Bend an Angle at will, then click the coordinate reference point and enter the password 1212. The actual Angle appears, enter the actual measured Angle, and the Angle is calibrated.The diagram below:2.5 length of calibration

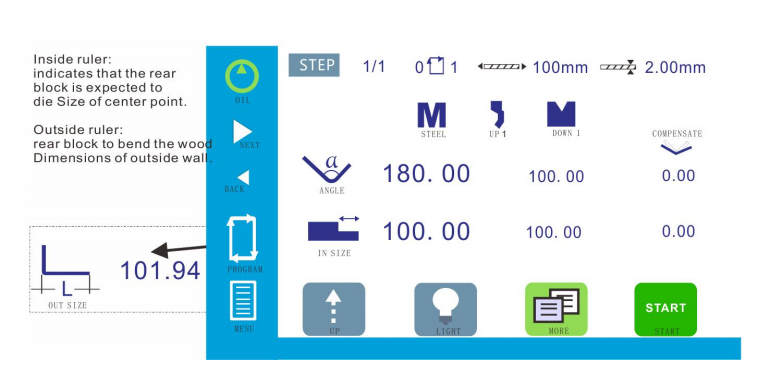

When the user uses the inner ruler to bend and inputs the size of the inner ruler as 100, if the actual measurement is 101, then click the menu into manual and change the coordinate reference point to 101. When the user uses the outside dimension to bend, if the actual outside dimension is 5, switch to the top of the outside dimension, enter 105, and then switch to the inside dimension. If the inside dimension is 103, click the menu into the manual and change the coordinate reference point to 103.

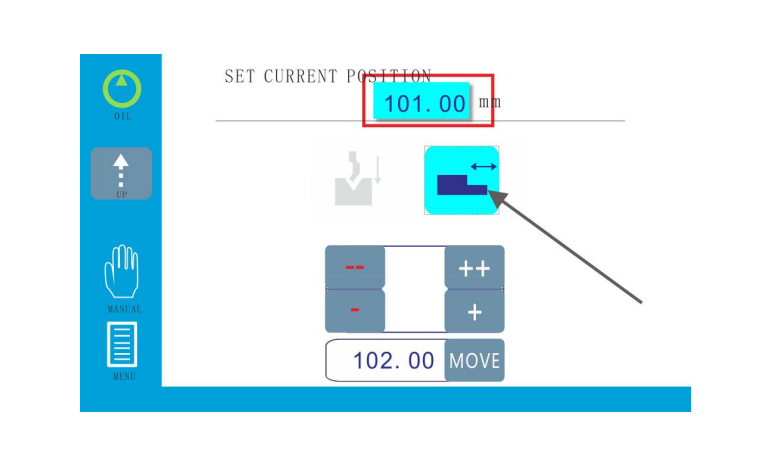

2.6 frame strength

When the user needs to bend the long board, because the long board has a larger rebound than the short board, so in the same Angle of folding, the long board should be pressed deeper than the short board, in order to correctly bend the required Angle.At this time, the frame strength of the material needs to be set, as shown in the figure below:2.7 grid ruler

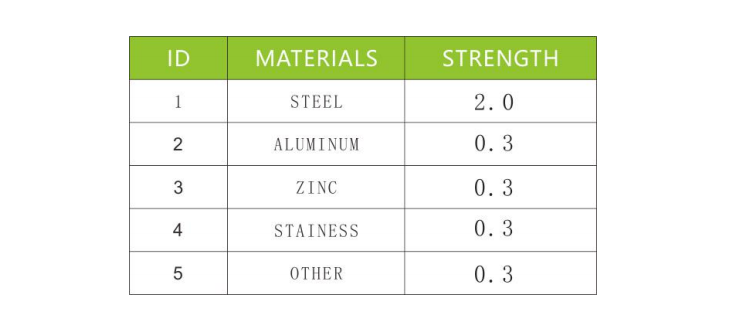

Before setting, please close the magnetic grid ruler first, step the upper mold and the lower mold to the flush position, then click the key to calibrate, the current position will automatically change to 0mm, then step on to stop the slider, check whether it will jack up the oil cylinder, and set the maximum limit position.

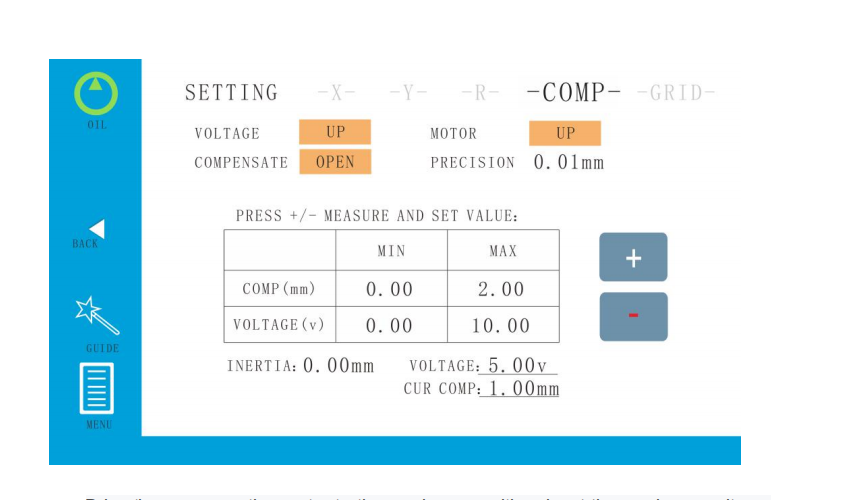

2.8 mechanical compensation

Drive the compensation motor to the maximum position, input the maximum voltage and the maximum height.Then the compensation motor is driven to the minimum position,input the minimum voltage and the minimum height.

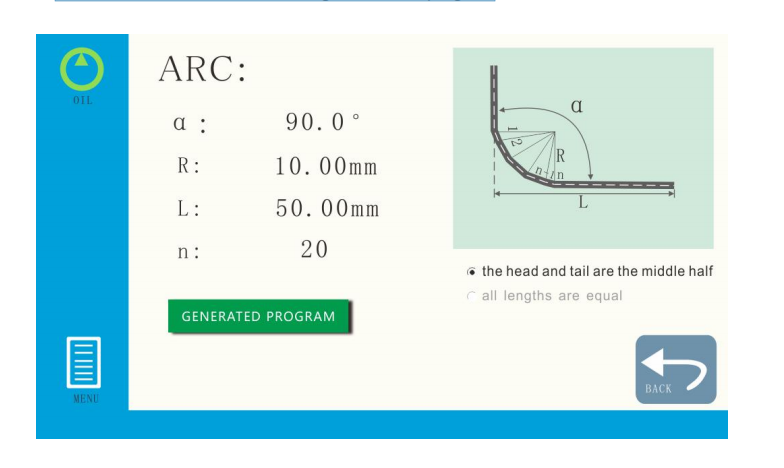

2.9 great arc

Para establecer el tamaño del arco, haga clic para generar el programa2.10 Y1-Y2 axis

3.user operation

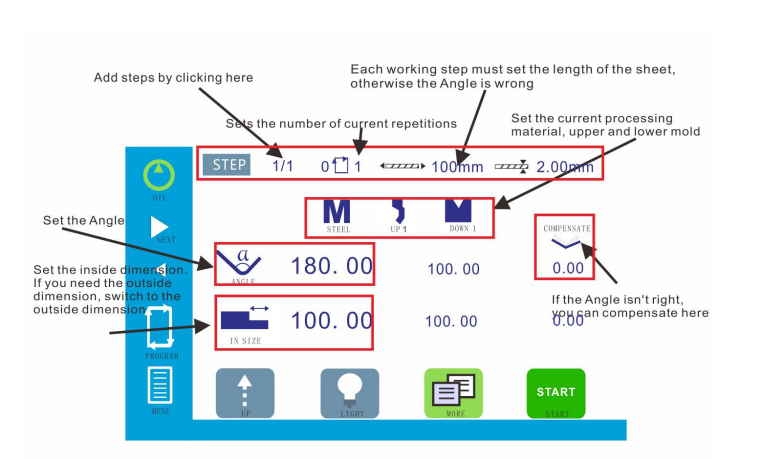

3.1 programación de un solo paso

El usuario sólo necesita un paso de mecanizado cuando3.2 programación multietapa

Pasos de programación: First set up the material, thickness, long plate and mold base, opening height and the speed change point, then set up the target size and bending Angle, set up after the firststep, click on add processing step by step number (see above), and then click the insert step sequence, at this point you can edit the second step, and so on, in the process of programming, will copy the programming of all parameters on the step。

4.common problem

1.2 Más programación

1.2 Más programación

1.3 parámetros avanzados

1.3 parámetros avanzados

Inching: Inching controlSingle: Automatic return after the end of a single bendContinuous: Automatic cycle operation

Inching: Inching controlSingle: Automatic return after the end of a single bendContinuous: Automatic cycle operation

Baja: Baja.

Desaceleración: Acción de presión.

Descarga: Acción de descarga.

Backhaul: Acción de retroceso.

Baja: Baja.

Desaceleración: Acción de presión.

Descarga: Acción de descarga.

Backhaul: Acción de retroceso.

Siguiendo los pasos anteriores, ya está listo para ajustar el ángulo de curvatura.

Siguiendo los pasos anteriores, ya está listo para ajustar el ángulo de curvatura.

When the user uses the inner ruler to bend and inputs the size of the inner ruler as 100, if the actual measurement is 101, then click the menu into manual and change the coordinate reference point to 101. When the user uses the outside dimension to bend, if the actual outside dimension is 5, switch to the top of the outside dimension, enter 105, and then switch to the inside dimension. If the inside dimension is 103, click the menu into the manual and change the coordinate reference point to 103.

When the user uses the inner ruler to bend and inputs the size of the inner ruler as 100, if the actual measurement is 101, then click the menu into manual and change the coordinate reference point to 101. When the user uses the outside dimension to bend, if the actual outside dimension is 5, switch to the top of the outside dimension, enter 105, and then switch to the inside dimension. If the inside dimension is 103, click the menu into the manual and change the coordinate reference point to 103.

Before setting, please close the magnetic grid ruler first, step the upper mold and the lower mold to the flush position, then click the key to calibrate, the current position will automatically change to 0mm, then step on to stop the slider, check whether it will jack up the oil cylinder, and set the maximum limit position.

Before setting, please close the magnetic grid ruler first, step the upper mold and the lower mold to the flush position, then click the key to calibrate, the current position will automatically change to 0mm, then step on to stop the slider, check whether it will jack up the oil cylinder, and set the maximum limit position.

Drive the compensation motor to the maximum position, input the maximum voltage and the maximum height.Then the compensation motor is driven to the minimum position,input the minimum voltage and the minimum height.

Drive the compensation motor to the maximum position, input the maximum voltage and the maximum height.Then the compensation motor is driven to the minimum position,input the minimum voltage and the minimum height.

Pasos de programación:

First set up the material, thickness, long plate and mold base, opening height and the speed change point, then set up the target size and bending Angle, set up after the firststep, click on add processing step by step number (see above), and then click the insert step sequence, at this point you can edit the second step, and so on, in the process of programming, will copy the programming of all parameters on the step。

Pasos de programación:

First set up the material, thickness, long plate and mold base, opening height and the speed change point, then set up the target size and bending Angle, set up after the firststep, click on add processing step by step number (see above), and then click the insert step sequence, at this point you can edit the second step, and so on, in the process of programming, will copy the programming of all parameters on the step。