CNC vs Manual Control in Hydraulic Shears: What Matters in Production

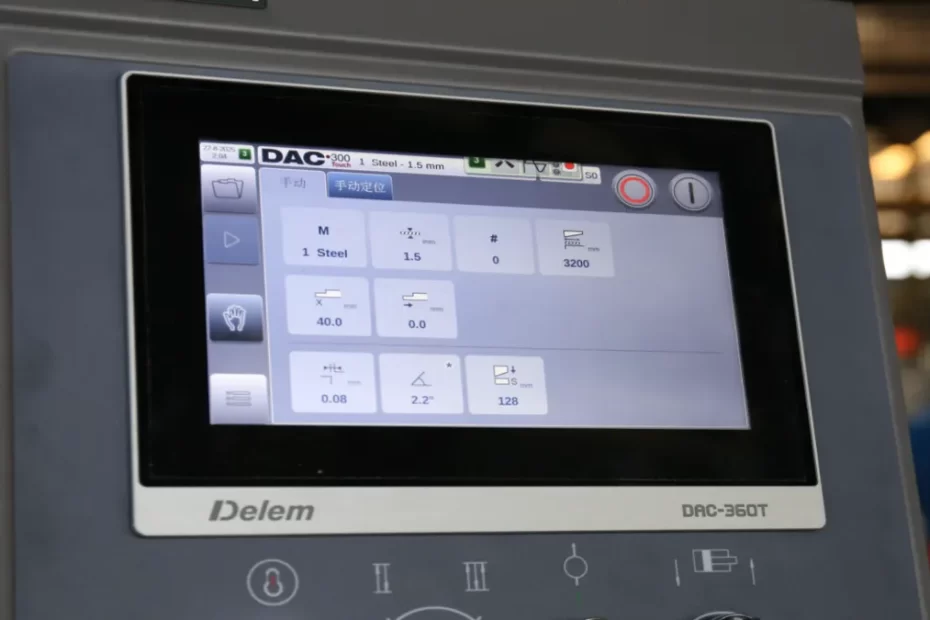

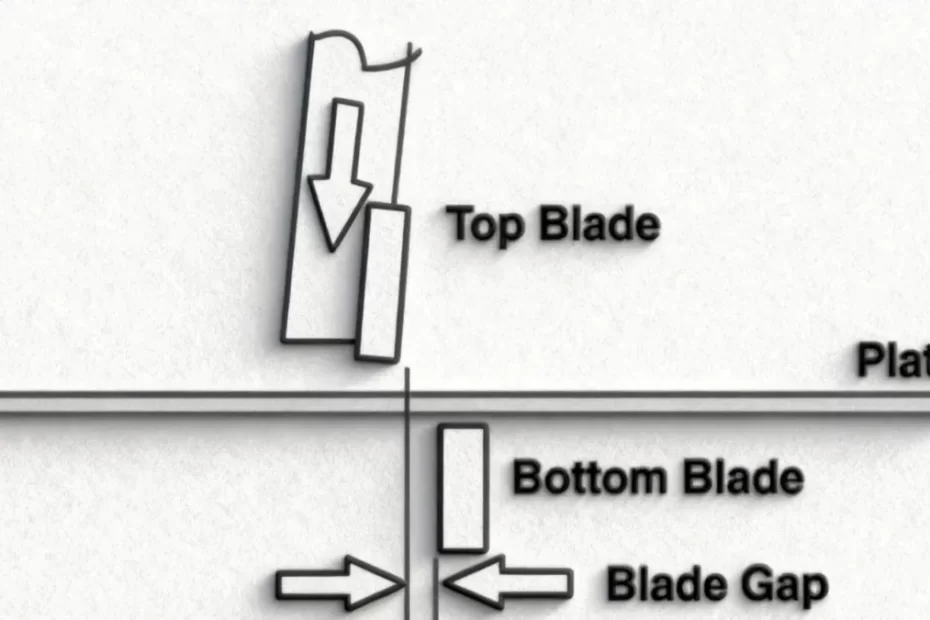

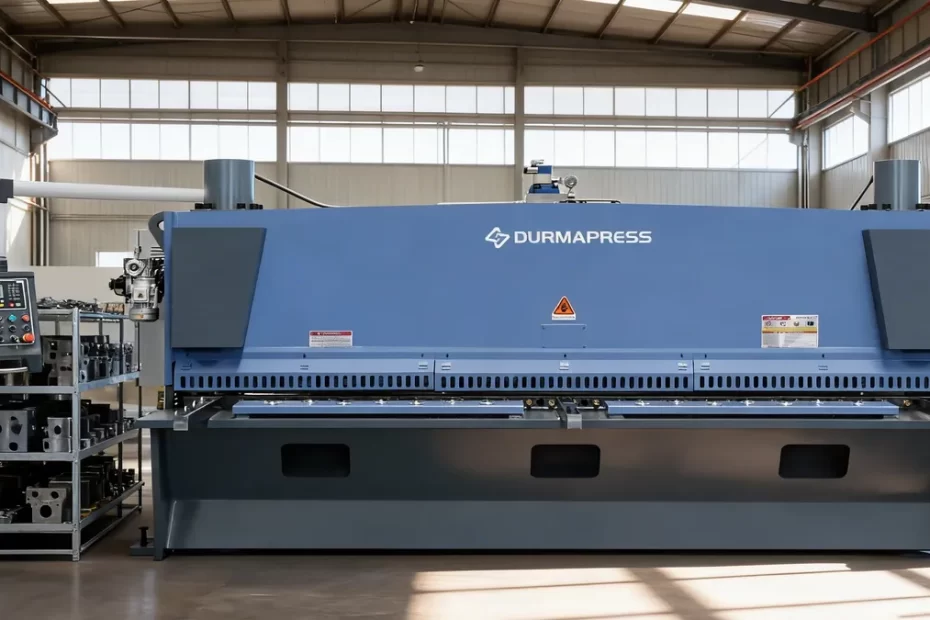

About Us Compare CNC and manual control in hydraulic shearing machines to understand their impact on accuracy, efficiency, operator dependency, and production cost in sheet metal fabrication. Contact Us Recent Posts Categories Follow Us Facebook-f Twitter Youtube Linkedin Instagram Weekly New Video https://www.youtube.com/watch?v=rExbe2wogNk In sheet metal fabrication, machine structure and blade quality are critical, but the control system often determines long-term production stability, efficiency, and accuracy.As manufacturing environments evolve toward higher precision and faster turnaround, many workshops face a practical… Ler mais "CNC vs Manual Control in Hydraulic Shears: What Matters in Production