О нас

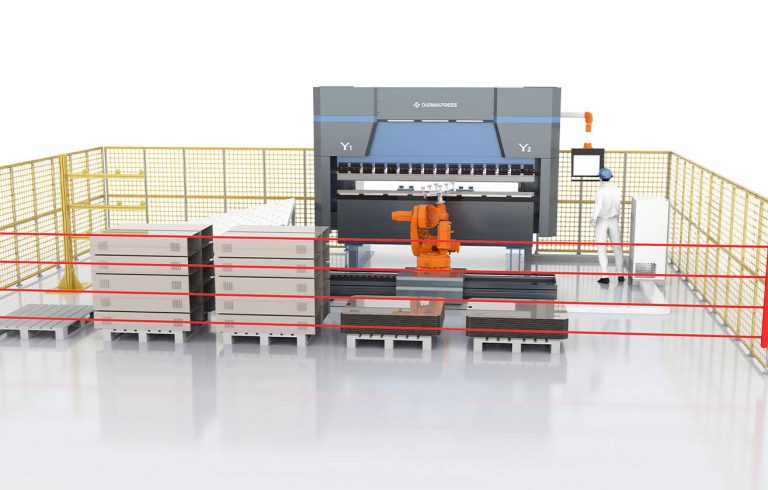

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Свяжитесь с нами

Последние сообщения

Категории

Следуйте за нами

Еженедельное новое видео

Введение

The global manufacturing industry is facing multiple challenges, including diversified demand, rapid product iteration, labor shortages, and high quality requirements. The development drivers of the global industrial robot industry mainly come from structural labor shortages and the growth of high-end manufacturing demand. The United States' "National Robotics Initiative 2.0," the European Union's "Horizon 2020" program, and China's "Smart Manufacturing 2025" all list industrial robots as a strategic focus. The downstream applications of industrial robots have widely covered numerous industries such as automotive, electronics, new energy, food, chemicals, and machinery manufacturing. The technological maturity and progress of core components of industrial robots are important guarantees for the healthy development of the robot industry. The performance of the control and electrical systems, including industrial robot controllers, servo systems, and teaching pendants, directly affects the overall performance and intelligence level of robots.

Basic Concepts, Definitions, Classification, and Composition of Industrial Robots

Definition of Industrial Robots

Industrial robots are multi-joint manipulators or multi-degree-of-freedom machine devices widely used in industrial fields. They possess a certain degree of autonomy and can rely on their own power sources and control capabilities to achieve various industrial processing and manufacturing functions. Industrial robots are widely applied in various industrial fields such as electronics, logistics, and chemicals.

Classification of Industrial Robots

Industrial robots can be classified by function into packaging, material handling, painting, transportation, welding, cleanroom, palletizing, and assembly robots. By mechanical structure type, they can be divided into multi-joint robots, SCARA robots, Cartesian coordinate robots, cylindrical coordinate robots, parallel robots, and automated guided vehicles (AGVs) for factory logistics.

Composition of Industrial Robots

Industrial robots typically consist of six subsystems: control system, drive system, execution system, perception system, decision-making system, and software components, as well as human-robot-environment interaction systems. The blue part in the figure below generally refers to the electrical control part, while the red part refers to the mechanical transmission part.

The core components of industrial robots include controllers, servo systems, and reducers, which determine important performance indicators of industrial robots such as precision, stability, and load capacity. These components represent the highest barrier in the industrial chain. The control system includes controllers, teaching pendants, and servo systems. The controller is the "brain" of the industrial robot, while the servo system is the "muscle" of the robot.

Application Status of Industrial Robots with Different Mechanical Structures

Multi-joint robots are widely used in industries such as automotive manufacturing, electronics assembly, and food processing for tasks like welding, assembly, transportation, and painting. For example, they are used for body welding and component installation in automotive manufacturing and for precision assembly on electronics production lines.

SCARA robots are mainly used for assembly tasks, such as component insertion on circuit boards and assembly of plastic parts. Since they specialize in horizontal motion, SCARA robots can move faster and are easier to integrate compared to cylindrical coordinate and Cartesian coordinate robots.

Parallel robots are used for rapid pick-and-place or product transfer applications, with main functions including grasping, packaging, and palletizing. For example, they quickly grasp products for boxing on packaging lines in the food and beverage industry and sort and package medicines in the pharmaceutical industry.

Cartesian coordinate robots are used in most industrial applications, offering flexibility in configuration to meet specific application needs. They provide high positioning accuracy and the ability to handle heavy objects, commonly used for transportation and material handling.

Cylindrical coordinate robots are mainly used for simple applications such as picking up, rotating, and placing materials. For example, they are used for goods picking and placing in warehouses and for simple material handling in manufacturing.

Collaborative robots can be used for automating repetitive and ergonomically challenging tasks, such as handling heavy parts, machine feeding, and final assembly. They are also used in the medical field to assist doctors in surgical operations and as teaching tools in the education field.

Development Trends in the Industrial Robot Industry

Obvious Trends of Intelligence, Integration, and Unification

With the advancement of power electronics technology, products at the control, drive, and execution levels will develop towards miniaturization, and the integration degree of the entire automation control system will become higher and higher. Integrated products of "control + drive" and "drive + execution" will become more and more popular, and may even develop towards integrated products of "control + drive + execution." Industrial robots will become intelligent terminals of a node, and solution providers that can create integrated intelligent manufacturing solutions covering the entire production process, the entire supply chain operation, and the entire lifecycle management will become the mainstream in the market.

Drive and control integration refers to the integration of the driver in the servo system with the upper-level controller to achieve the purpose of reducing volume, reducing weight, and improving performance. Drive and control integration can effectively improve the flexibility and reliability of the servo system while reducing costs, enabling the servo system to complete complex control algorithms in a shorter time. By sharing memory to transmit more control and dynamic information in real time, the internal communication speed is increased.

In recent years, both domestic and foreign enterprises have successively launched drive and control integration products. Integrated integration is not limited to the integration between drivers and controllers, but also applies to the integration between drivers and motors. Traditional controllers, servo drivers, and servo motors can be integrated in pairs to simplify the structure and improve efficiency with the idea of integrated integration.

Continuous Acceleration of Technological Innovation

In the current field of industrial automation and intelligent manufacturing, the innovation of industrial robot technology is accelerating at an unprecedented speed. This not only greatly expands its application scope but also improves production efficiency and flexibility. This technological progress is mainly due to the comprehensive application of artificial intelligence (AI), machine learning, advanced sensing technology, cloud computing, and the Internet of Things (IoT), enabling industrial robots to perform more complex tasks and achieve higher levels of autonomy and intelligence.

In the future, the innovation of industrial robot technology will be mainly reflected in several aspects: First, enhanced perception capabilities, through the integration of more advanced vision and tactile sensors, robots can more accurately identify and manipulate objects with complex or unknown shapes, enabling them to work efficiently even without supervision. Second, through the application of machine learning and AI algorithms, industrial robots can learn from experience and optimize their operating strategies, achieving self-adjustment to adapt to changes on the production line.

Continuous Expansion into Emerging Application Fields

With the continuous progress of industrial robot technology, it will be more deeply applied in traditional manufacturing industries and will also open up a wide range of application prospects in non-traditional fields. At present, the application scope of industrial robots is rapidly expanding. In addition to traditional industries such as automotive manufacturing, electronics, and electrical manufacturing, it has gradually extended to emerging fields such as healthcare, agriculture, environmental monitoring, and the service industry. For example, in the medical field, robots can assist or directly perform precise surgical operations through a combination of fine manipulation capabilities and remote control technology; in the agricultural field, robots can achieve precise crop planting and management through the integration of various sensors and data analysis technologies, thereby increasing yield and resource utilization efficiency.

According to a report by Grand View Research, the global medical robot market is expected to achieve a compound annual growth rate of 17.3% between 2020 and 2027. This growth is partly due to the expansion of robot technology applications in surgical assistance, rehabilitation, drug distribution, and laboratory automation.

A study by MarketsandMarkets predicts that the global agricultural robot market size will grow from $4.8 billion in 2020 to $12.5 billion in 2025, with a compound annual growth rate of 21.1%. This reflects the potential of robot technology to improve agricultural production efficiency and reduce labor demand.

Although the market for industrial robots in emerging application fields is still in its early stages of development, it is showing significant growth potential. In the future, as industrial robot application technology continues to mature and accumulate, the application fields of industrial robots will be further expanded.

It can be foreseen that with the maturity and industrial implementation of the above technologies, intelligent manufacturing industrial robots will truly become the core enabling technology of high-end equipment manufacturing. Factory production will inevitably develop towards automation and intelligence, and the intelligent factory is an irreversible trend.