О нас

Learn how to troubleshoot CNC press brakes with common problems and fixes. Improve your press brake bending, maintain pressing punches, and optimize press brake operation.

Свяжитесь с нами

Последние сообщения

Категории

Следуйте за нами

Еженедельное новое видео

what is a press brake machine

CNC press brakes are essential machines in modern manufacturing, providing precision in metal forming and bending processes. Proper press brake operation ensures that each bend meets the required specifications, minimizing material waste and maximizing production efficiency.

A press brake operator plays a critical role in overseeing the machine, from setting bending parameters to monitoring the bending process. While modern CNC systems automate much of the operation, human oversight remains essential for identifying and resolving issues before they impact production. Even minor misalignments in tooling or incorrect programming can lead to inconsistencies in press brake bending, highlighting the importance of operator expertise.

Common Problems in Press Brake Bending

1. Inaccurate Bends

One of the most frequent issues in press brake bending is inaccurate bends. This may result from worn pressing punch or misaligned punch presses, incorrect bend angles, or improper material handling. Even a minor deviation in a mechanical press brake setup can create noticeable bending errors. Regular inspections of tooling and calibration are essential to maintain consistent bending quality.For a deeper explanation of bend angle calculation and springback control, check our complete press brake bending guide.

2. Material Deformation

Material deformation, such as warping or uneven bends, often occurs when the metal thickness or type does not match the machine settings. A skilled press brake operator must adjust the machine’s pressure, speed, and bending parameters to accommodate different materials, ensuring precise results and reducing scrap rates.

3. Hydraulic and Mechanical Failures

Both hydraulic and mechanical press brake systems are susceptible to wear. Common issues include oil leakage, reduced hydraulic pressure, worn mechanical linkages, or insufficient lubrication. These failures reduce bending effectiveness and may cause long-term damage if not addressed promptly.

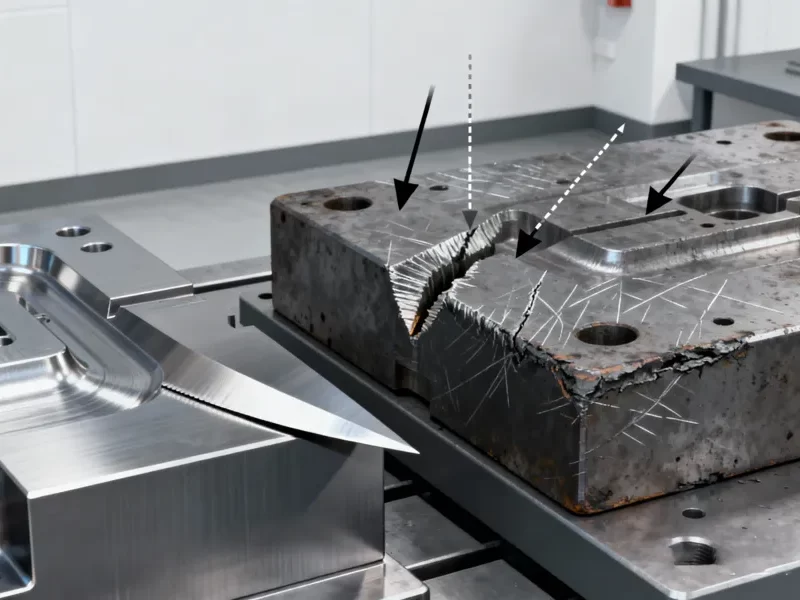

4. Tooling and Punch Issues

The pressing punch and punch presses are critical to quality bends. Worn or damaged tooling can lead to uneven bending, surface marks, or incomplete folds. Regular maintenance, alignment checks, and timely replacements are crucial to avoid these tooling-related problems.You can also review our tooling selection page for optimized punch and die matching in different materials: pressing punch & punch presses solutions.

5. Control System and Software Errors

Modern CNC press brakes rely on sophisticated control systems. Faulty sensors, outdated software, or misprogrammed bend sequences can trigger errors or halt operations. While some issues can be solved by resetting the system, persistent errors may require professional service.

Troubleshooting Techniques for Press Brake Issues

1. Diagnosing Bending Inaccuracies

Begin by inspecting the pressing punch and punch presses for wear or misalignment. Verify that material thickness matches the programmed settings, and check that the mechanical press brake or hydraulic system is properly calibrated. Often, minor adjustments in tooling or bend angles can resolve inaccuracies.

2. Addressing Hydraulic and Mechanical Problems

For hydraulic issues, check oil levels, replace contaminated fluid, and inspect pumps and valves. In mechanical press brake systems, examine bolts, linkages, and lubrication. Timely intervention preserves machine performance and ensures consistent press brake bending.

3. Resolving Control System Errors

If you encounter control panel errors, restart the CNC system, update software, and inspect electrical connections. Confirm that sensors and switches are functioning. Maintaining up-to-date software and properly functioning components reduces unexpected downtime.

4. Tooling Maintenance and Replacement

Consistent maintenance of pressing punch and punch presses is essential. Regular inspection, alignment, and replacement of worn components extend tool life, improve bending accuracy, and minimize machine failures.

5. Operator Training and Preventive Practices

A skilled press brake operator is the first line of defense against operational issues. Training in proper press brake operation, routine inspections, and understanding common failure points allows operators to identify and resolve problems early, ensuring smooth production.

Preventive Maintenance and Best Practices

Preventive care is vital for long-term machine performance. Press brake maintenance tips include:

- Regular inspection of pressing punch and punch presses

- Calibration of mechanical press brake systems

- Checking hydraulic fluid levels and replacing contaminated oil

- Routine cleaning and lubrication

- Maintaining logs of machine performance and repairs

By investing in preventive maintenance, manufacturers can extend the service life of their CNC press brakes and ensure consistent quality in press brake bending operations.

When Professional Help is Needed

Despite the best preventive measures, some issues require professional attention. Complex hydraulic failures, repeated control system errors, or significant mechanical wear often exceed the troubleshooting capabilities of an in-house operator. Understanding what is a press brake operator also involves knowing the limits of personal expertise and when to escalate problems.

Professional service ensures that critical components such as punch presses and hydraulic systems are repaired or replaced correctly, minimizing the risk of recurring faults. Regular collaboration with trained technicians also helps operators gain insights into more advanced troubleshooting techniques and machine optimization strategies.

Заключение

CNC press brakes are indispensable tools in modern sheet metal fabrication, but they are not immune to problems. Understanding press brake operation, recognizing the signs of wear in pressing punch and punch presses, and addressing both mechanical press brake and hydraulic issues promptly are essential for maintaining production quality. With a combination of preventive maintenance, operator expertise, and timely professional support, manufacturers can ensure consistent performance, reduce downtime, and extend the life of their machines.

Whether you are a seasoned press brake operator or new to the field, mastering troubleshooting techniques for press brake bending issues is key to operational efficiency and product quality. Regular inspections, careful monitoring, and adherence to best practices create a foundation for long-term success in metal forming operations.

FAQ – CNC Press Brake Troubleshooting

A press brake operator manages CNC press brake setup, monitors press brake operation, ensures accurate press brake bending, and performs routine maintenance. They also identify minor issues with pressing punch or punch presses early.

Regular inspection and maintenance are key. Check pressing punch and punch presses, maintain proper alignment, and follow manufacturer guidelines for press brake operation.

Issues include uneven bends due to worn tooling, hydraulic inconsistencies, control system errors, and misalignment in mechanical press brake components.

Typically every 3–6 months, including inspection of pressing punch, hydraulic oil, and electrical components.

Updates may fix control errors, but mechanical problems with punch presses, pressing punch, or mechanical press brake require physical inspection and adjustment.

Complex hydraulic failures, repeated control errors, or severe mechanical wear require professional service. Even an experienced press brake operator should know the limits of troubleshooting.