О нас

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Свяжитесь с нами

Последние сообщения

Категории

Следуйте за нами

Еженедельное новое видео

Project Overview

Today, Durmapress is proud to announce the successful shipment of five DP-Eco 63T2500 hydraulic press brakes, complete with precision bending molds, to our valued customer in Iran. This project marks another milestone in Durmapress’s ongoing commitment to delivering high-performance metal fabrication machinery to customers worldwide.

The Iranian client specializes in custom sheet metal fabrication and required a reliable solution for high-accuracy bending operations in stainless steel and mild steel production. After several rounds of technical consultation, Durmapress’s engineering team recommended the DP-Eco 63T2500 series, known for its balance between compact structure, precision control, and energy efficiency.

From equipment configuration to shipment coordination, every step of this industrial equipment export was managed under Durmapress’s strict international logistics standards to ensure seamless delivery and installation readiness upon arrival.

Equipment Configuration

DP-Eco 63T2500 Hydraulic Press Brake — Precision Meets Productivity

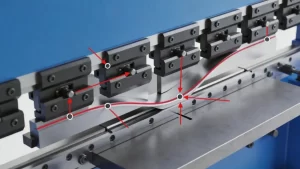

The DP-Eco 63T2500 is a compact yet powerful hydraulic press brake, featuring a 63-ton bending force and a 2,500mm working length, perfectly suited for mid-size sheet metal parts. Each machine is equipped with:

High-precision backgauge system powered by a servo motor for stable repeatability.

Delem CNC control system, allowing easy programming and precise multi-step bending.

Heavy-duty steel frame treated with stress-relief annealing to ensure long-term accuracy.

Integrated hydraulic system with fast response, minimal noise, and energy-efficient performance.

Bending Molds — Custom-Made for Precision Work

To meet the customer’s diverse production needs, Durmapress supplied a complete set of upper and lower bending molds, each tailored for high repeatability and tight bending radii. The molds are made from 42CrMo steel and heat-treated to withstand high loads and maintain consistent forming angles.

Together, the press brakes and molds create a versatile and efficient production line that allows the Iranian client to expand output capacity while maintaining precision and consistency in every part produced.

Secure Packaging & Shipping Process

Durmapress’s logistics team applied multi-layer protection and reinforced container loading techniques to ensure the machines arrived safely in Iran.

Reinforced Base and Frame Securing:

Each DP-Eco 63T2500 unit was mounted on a solid wooden base with vibration-dampening pads. The machines were then anchored using industrial steel cables attached to the base frame, preventing lateral movement during transit.Protective Wrapping and Moisture Control:

All machines were covered in high-strength waterproof film, tightly sealed to block humidity, rain, and condensation—common challenges in long-distance maritime transport. For additional moisture protection, desiccant packs were placed inside the wrapping.Component Protection:

Sensitive components, such as the CNC control panel and hydraulic fittings, were cushioned with impact-resistant foam and enclosed in custom wooden frames to prevent accidental damage or scratches.Container Optimization:

The five machines were efficiently loaded into a 40HQ container, ensuring balanced weight distribution. The internal layout was designed to minimize empty space and vibration risk during transport.

This systematic Hydraulic bending machine shipping process exemplifies Durmapress’s logistics precision and dedication to equipment integrity.

Logistics Team Statement

“Our logistics department treats every shipment as a mission,” said Mr. Liu, Durmapress Logistics Manager.

“For this project, we implemented a double-securing method—steel cables for structural stability and industrial straps for cushioning. The goal is simple: to ensure every Durmapress machine arrives at our customer’s site in perfect working condition. From the moment it leaves our warehouse to the time it reaches Iran, our responsibility is total.”

This statement reflects Durmapress’s professional handling standards and unwavering commitment to customer trust and product safety.

Global Service Commitment

With this shipment to Iran, Durmapress once again demonstrates that our service extends far beyond manufacturing. Each successful delivery reinforces our position as a trusted global supplier of metal fabrication machinery—combining engineering excellence, logistical reliability, and comprehensive after-sales support.

From CNC press brakes and fiber laser cutters to shearing machines and punch presses, Durmapress continues to provide full metalworking solutions for industrial clients in more than 120 countries. Our focus remains constant: delivering equipment that empowers manufacturers to achieve higher efficiency, lower costs, and superior precision.

As the five DP-Eco 63T2500 press brakes set sail for Iran, they carry not just machinery—but Durmapress’s promise of reliability, innovation, and partnership that transcends borders.

Stay Updated on Industrial Innovations

Subscribe to our newsletter for the latest insights on manufacturing technology, sustainability, and industry trends.