When the robotic arms in traditional factories start to independently perceive production rhythms, and when supply chains can predict market fluctuations through data, the industrial sector is undergoing a profound transformation driven by Industry 4.0 and smart manufacturing. This transformation is not just an iteration of technologies, but a comprehensive reshaping of production paradigms, business models, and even industrial ecosystems.

Smart Manufacturing and Industry 4.0

The concept of smart manufacturing originated in the late 1980s. Professor P.K. Wright from New York University and Professor D.A. Bourne from Carnegie Mellon University published the book Manufacturing Intelligence, in which they first proposed the concept of smart manufacturing. They pointed out that the purpose of smart manufacturing is to model the skills and expert knowledge of manufacturing technicians through the integration of knowledge engineering, manufacturing software systems, machine vision, and machine control, enabling intelligent machines to carry out small-batch production without manual intervention.

The manufacturing industry is shifting from traditional models to digitalization, networking, and intelligentization; from extensive development to quality-and-efficiency-oriented development; from high pollution and high energy consumption to green manufacturing; and from production-oriented to "production + service" oriented. In this transformation process, smart manufacturing is an important means.

A widely accepted definition of smart manufacturing is: For the entire product lifecycle, based on new-generation information technology and with manufacturing systems as the carrier, it has certain capabilities of independent perception, learning, analysis, decision-making, communication, and coordinated control in key links or processes, enabling it to dynamically adapt to changes in the manufacturing environment to achieve certain optimization goals.

The above definition puts forward clear goals and expectations for smart manufacturing—high efficiency, low cost, and high quality—and provides methodological guidance for its realization path. It emphasizes independent perception: through the interconnection of all things, connecting all digitizable objects, and using data and algorithms to acquire intelligence. Smart manufacturing not only adopts new manufacturing technologies and equipment but also infiltrates the rapidly developing information and communication technologies into factories, building Cyber-Physical Systems (CPS) in the manufacturing field, changing the production organization methods and interpersonal relationships in the manufacturing industry, and bringing innovative changes in R&D and manufacturing methods as well as business models.

Since the 19th century, we have experienced three industrial revolutions. They are called "revolutions" because the innovations driving them not only slightly improved productivity and efficiency but also completely changed the way goods are produced and work is done. Now, we are entering the fourth industrial revolution, namely Industry 4.0.

This concept was first proposed by the German government and officially launched at the 2013 Hannover Messe. With the arrival of a new wave of technologies and the increasingly fierce international technological competition, Germany, as an industrial power, keenly sensed new opportunities and challenges. Therefore, it promptly formulated and promoted an industrial development and innovation strategy, aiming to enhance the competitiveness of German industry and take the lead in the new round of industrial revolution.

Since its launch, Industry 4.0 has quickly triggered a new round of industrial transformation competition worldwide. German academic and industrial circles believe that the concept of Industry 4.0 is the fourth industrial revolution led by smart manufacturing, which aims to promote the transformation of manufacturing towards intelligentization through the combination of information and communication technologies and cyber-physical systems.

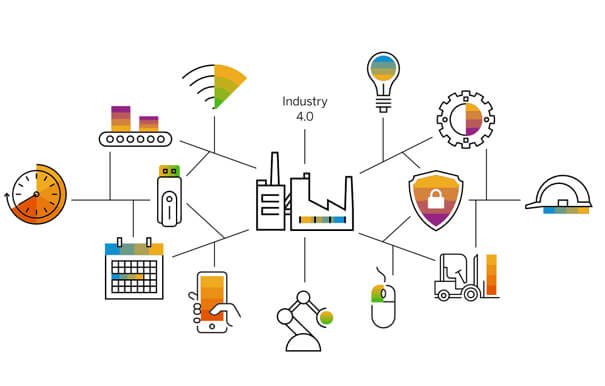

Industry 4.0 relies on nine technical pillars: 1. Big data and artificial intelligence analytics; 2. Horizontal and vertical integration;3. Cloud computing; 4. Augmented reality (AR); 5. Industrial Internet of Things; 6. Additive manufacturing/3D printing; 7. Autonomous robots; 8. Simulation/digital twins; 9. Cybersecurity.

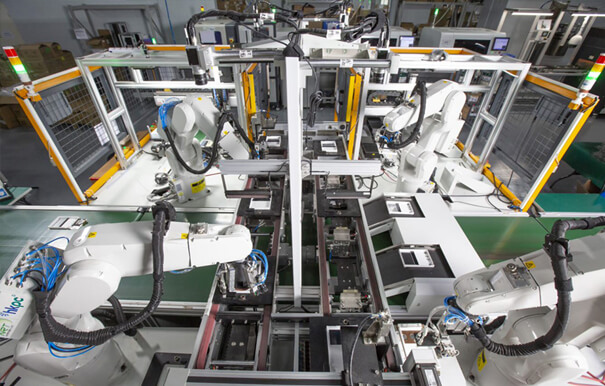

These innovative technologies connect the physical world and the digital world, making intelligent autonomous systems possible. Although enterprises and supply chains are already using some of these advanced technologies, only the comprehensive application of these innovative achievements can fully release the full potential of Industry 4.0. The valuable opportunity for the manufacturing industry to move towards the fourth industrial revolution stems from the development of smart factories. Sensors in factory workshops collect massive amounts of big data, which not only make the real-time status of manufacturing assets visible but also provide tool support for predictive maintenance, thereby minimizing equipment downtime.

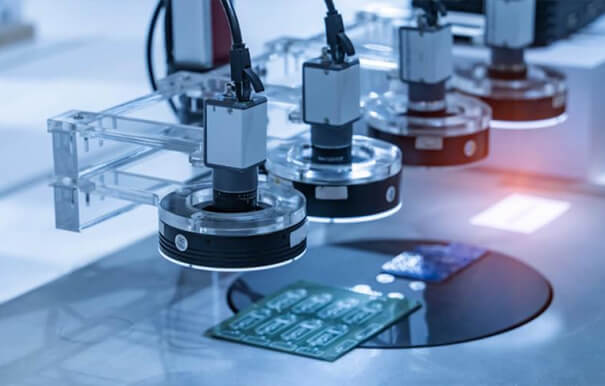

The application of high-tech IoT devices in smart factories helps improve production efficiency and product quality. Replacing manual inspection models with AI-driven visual recognition can reduce errors in the manufacturing process while saving costs and time. Quality control personnel only need to invest a small amount of money to configure smartphones connected to the cloud to achieve remote monitoring of the manufacturing process. With the help of machine learning algorithms, manufacturers can detect errors in a timely manner, avoiding handling them at a later stage when maintenance costs are higher.

The concepts and technologies of Industry 4.0 have a wide range of applications. Various industrial enterprises, whether in discrete manufacturing, process manufacturing, or other industrial fields such as oil and gas, mining, can apply them.

The Path of OT and IT Integration

For a long time, Operation Technology (OT) and Information Technology (IT) have been isolated from each other, with different goals and developing along different paths. The gap between them has prevented factories from making full use of important information that they have mastered but not yet explored.

There have been continuous debates about the integration of OT and IT, mainly reflected in two aspects: one is around concepts, requiring clarification of the concepts and boundaries of OT and IT; the other is at the level of company organization and planning implementation, such as which department takes the lead, the scope of implementation, and the expected benefits.

Wikipedia defines OT as: Hardware and software specifically used to directly monitor or control physical devices (such as valves, pumps, etc.) to detect physical processes or cause changes in physical processes.

For example, technologies related to on-site control and detection, including Programmable Logic Controllers (PLC), Distributed Control Systems (DCS), Supervisory Control And Data Acquisition (SCADA), as well as various instruments, sensors, and mechanical equipment, also include the implied production processes, production technologies, and knowledge.

OT directly faces the physical equipment and processes of industrial production, ensuring their safe and stable operation. Its primary goal is to complete product production with guaranteed quality and quantity. For a long time, it has adopted dedicated systems, networks, and software. In this sense, compared with IT, the openness and standardization of OT need to be improved and enhanced. IT mainly refers to various technologies used to manage and process information, which apply computer science and communication technology to design, develop, install, and implement information systems and application software.

IT represents the computer industry, such as computing, storage, networks, cloud computing, databases, etc. Common enterprise operation and management systems such as Enterprise Resource Planning (ERP), Product Lifecycle Management (PLM), Customer Relationship Management (CRM), and Supply Chain Management (SCM) all belong to the scope of IT.

The integration of OT and IT is not easy. OT and IT in enterprises are completely two groups of people, with great differences in their knowledge and thinking when looking at problems. OT personnel prefer PLC, DCS, SCADA, HMI, RTU, data acquisition, and embedded computing technologies, while IT personnel are proficient in Internet technologies, with a good command of rapidly expanding network scales, cloud computing infrastructure, web-based deployment, and technologies such as SQL, Java, and big data.

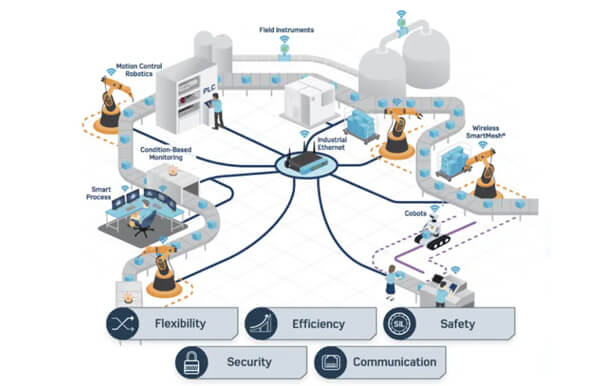

In the era of smart manufacturing and Industry 4.0, the integration of IT and OT is also an inevitable path, which depends on top-level design and organizational design or even restructuring at the business and technical levels. By enhancing their respective capabilities, a truly disruptive technology can be formed, which is where the Industrial Internet of Things plays its role as a specific realization of OT and IT integration.

In terms of technology, the integration of OT and IT still faces some practical problems. Firstly, there is the issue of unified data transmission interfaces and standards. OT commonly uses fieldbuses and industrial Ethernet, which have high requirements for data real-time performance and transmission determinism, with low network transmission jitter. In contrast, IT is usually non-real-time, with second-level responses being sufficient, and the network mainly uses standard Ethernet. The integration of OT and IT must first solve the problems of network interconnection and data intercommunication.

Secondly, take a typical medium-sized factory as an example. It usually has multiple devices purchased in different periods from different suppliers, and the automation levels, software and hardware platforms, and communication protocols of different suppliers are different, making data collection, integration, and scenario standardization very difficult. Some equipment manufacturers even regard data analysis insights as value-added services, and factories have to pay to use them, which further hinders data acquisition.

In addition to differences, due to considerations of process confidentiality and security isolation, many OT systems were not designed to open data during their design. Some manufacturing sites operate well without the participation of IT systems, and the urgency is not as high as imagined. At this time, it is necessary to comprehensively consider economy and the long-term strategy of the enterprise. Only when there is a full understanding of the value driven by data can we make up our minds to promote the integration of OT and IT.

Enterprise Digital Transformation

In addition to differences, due to considerations of process confidentiality and security isolation, many OT systems were not designed to open data during their design. Some manufacturing sites operate well without the participation of IT systems, and the urgency is not as high as imagined. At this time, it is necessary to comprehensively consider economy and the long-term strategy of the enterprise. Only when there is a full understanding of the value driven by data can we make up our minds to promote the integration of OT and IT.

1.Information Digitization Basics

The first is the digitization of information, such as the conversion from analog signals to digital signals, or from manual bookkeeping to Word documents. Essentially, it is to read, write, store, and transmit information in the form of binary digitization.

2.Process Digitization and Efficiency Enhancement

The second is the digital enhancement of process efficiency or process digitization. For example, enterprise resource planning systems, customer relationship management systems, supply chain management systems, and warehouse management systems all digitize work processes, thereby improving work collaboration efficiency, resource utilization efficiency, and creating information value for enterprises. In these two stages, the business model of the enterprise may not undergo fundamental changes. For example, an automobile manufacturing enterprise, although it has realized informatization, still mainly sells automobiles.

3.Digital Transformation and Business Model Innovation

The third is digital transformation, focusing on achieving "digitization of business" to enable the company to obtain new business models and core competitiveness. For example, with the help of digital technologies, an automobile seller may transform into a mobility service provider with automobiles as the carrier. Large engineering machinery enterprises, seeking new profit growth points, provide equipment leasing services and use the Industrial Internet of Things to remotely and real-time monitor the operation status and location of equipment to ensure the safety and effectiveness of the leasing service model. Before this, enterprises needed to invest a lot of manpower to manage leased equipment.

There are many reasons for digital transformation, including pressures from the market and supervision. The market is rapidly changing, including existing or upcoming pressures. To respond to such changes and competition, enterprises need to continuously improve internal process efficiency, accelerate product innovation, and provide value-added services to form sustainable competitiveness.

For R&D and manufacturing enterprises, although digital transformation is supported by digital technologies, digital technologies themselves are not the goal. Their essence is business transformation, which must be led by the enterprise's strategy and is a business change under strategic leadership.

Digital transformation should be guided by customer needs, guaranteed by organizational change, process optimization, and personnel capabilities, and promoted by corporate culture and environmental opportunities. It is the improvement of R&D, production, operation, and services driven by data and empowered by intelligence; it is the integration of OT and IT; it is the application of digital technologies such as digitization, networking, and intelligentization. The Internet, Internet of Things, big data, cloud computing, artificial intelligence, and 5G communication all belong to digital technologies.

В Industrial Digital Transformation White Paper , first released by the Industrial Internet Consortium (IIC) in 2020, for the industrial field, it proposed the definition of industrial digital transformation: Industrial digital transformation is the use of the Internet of Things to improve processes and operations and achieve better results, characterized by the integration of IT and OT.

In industrial digital transformation, sensor-based data and data-driven innovative applications will affect personnel, operations, business, and the physical environment, and create better business results. The book Reconstruction: The Logic of Digital Transformation proposes that the essence of digital transformation lies in using the automatic flow of data in a world defined by data + algorithms to resolve the uncertainty of complex systems, optimize resource allocation efficiency, and build new competitive advantages for enterprises.

In industrial digital transformation, sensor-based data and data-driven innovative applications will affect personnel, operations, business, and the physical environment, and create better business results. The book Reconstruction: The Logic of Digital Transformation proposes that the essence of digital transformation lies in using the automatic flow of data in a world defined by data + algorithms to resolve the uncertainty of complex systems, optimize resource allocation efficiency, and build new competitive advantages for enterprises.

To sort out the context: digital transformation will change the way enterprises create value for customers, and digital technologies will reduce the resistance to business transformation or development. Smart manufacturing and Industry 4.0 are digital transformation strategies for industry, requiring close integration of OT and IT, while the Industrial Internet of Things is an important enabling technology and key implementation path for smart manufacturing and Industry 4.0.

О нас

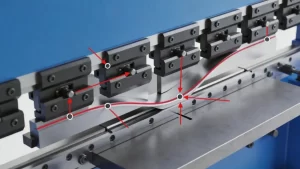

Durmapress специализируется на проектировании, производстве и продаже различного металлообрабатывающего оборудования, включая гибочные станки, ножницы, пуансоны, станки для лазерной резки и т. д. Компания была основана в 2000 году. Благодаря многолетнему опыту и накоплению технологий. DurmaPress стал одним из известных брендов металлообрабатывающего машиностроения Китая.

Свяжитесь с нами

Последние сообщения

Категории

Следуйте за нами

Еженедельное новое видео

Свяжитесь с нами для получения дополнительной информации

Если у вас есть какая-либо информация о нашей продукции, пожалуйста, свяжитесь с нами, и мы ответим вам в течение 24 часов.