О нас

Durmapress successfully delivered a BS3015H-6000W fiber laser cutting machine to Canada, supporting efficient sheet metal cutting with secure packaging and global service.

Свяжитесь с нами

Последние сообщения

Категории

Следуйте за нами

Еженедельное новое видео

Project Overview

Durmapress recently completed the successful shipment of one BS3015H-6000W станок для лазерной резки волокна to Canada, supporting a local manufacturing company focused on sheet metal processing and custom fabrication.

The Canadian customer specializes in precision components for industrial equipment and construction applications. With increasing order volumes and higher requirements for cutting accuracy, they selected the BS3015H series CNC laser cutting machine to upgrade their production capacity, improve cutting efficiency, and ensure consistent quality across a wide range of metal materials.

This shipment reflects Durmapress’s continued expansion in North America and our commitment to delivering reliable laser cutting solutions to global markets.

Equipment Configuration

BS3015H-6000W Fiber Laser Cutting Machine (1 Unit)

- High cutting speed and accuracy – The CNC control system enables precise motion control, producing clean edges and consistent dimensions.

- Strong material versatility – Suitable for thin to medium-thickness plates, supporting diverse production needs in metal fabrication.

- Stable mechanical structure – The heavy-duty welded frame reduces vibration and improves overall cutting quality.

- Intelligent operating system – User-friendly software allows quick nesting, parameter adjustment, and job switching, helping operators maximize productivity.

- Energy-efficient fiber laser technology – Lower operating costs compared to traditional cutting methods, while maintaining excellent processing results.

In daily production, this CNC laser cutting machine integrates smoothly with downstream bending and welding processes, creating an efficient workflow from raw sheets to finished components. By automating cutting operations and reducing manual handling, the BS3015H-6000W helps the customer shorten lead times and improve overall manufacturing efficiency.

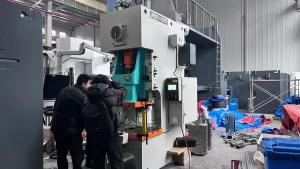

Secure Packaging & Shipping Process

For international delivery to Canada, Durmapress implemented a comprehensive packaging and shipping plan to protect the fiber laser cutting machine throughout long-distance transportation.

Before packing, all exposed metal parts were treated with anti-rust oil, and sensitive components such as the laser head and electrical cabinets were wrapped with moisture-proof film. Each module was carefully inspected to ensure it met export standards.

Logistics Team Statement

“Our goal is to deliver not only machines, but confidence,” said the Durmapress Logistics Manager.

“Every fiber laser cutting machine represents a significant investment for our customers. From final inspection to container loading, we follow strict standards for packaging and transportation. Through steel cable fixation, anti-vibration protection, and moisture control, we make sure each shipment reaches its destination safely and on schedule.”

This hands-on approach reflects Durmapress’s commitment to equipment safety and long-term customer satisfaction.

Global Service Commitment

The successful delivery of the BS3015H-6000W to Canada highlights Durmapress’s strong global logistics capability and professional project coordination. With installations across North America, Europe, Asia, and the Middle East, we continue to support manufacturers with advanced fiber laser cutting machines and complete sheet metal processing solutions.

From equipment selection and technical consultation to export packing and after-sales support, Durmapress provides end-to-end service tailored to each customer’s production goals.

Whether supplying a single CNC laser cutting machine or a full fabrication line, we remain dedicated to helping partners improve efficiency, reduce operating costs, and achieve sustainable growth.

Durmapress looks forward to building more long-term partnerships worldwide through reliable equipment, professional service, and consistent delivery performance.