О нас

Explore the top applications of robotic press brakes in Industry 4.0 factories. Learn how smart automation, CNC integration, and robotic arms transform sheet metal bending.

Свяжитесь с нами

Последние сообщения

Категории

Следуйте за нами

Еженедельное новое видео

Introduction: The Role of Robotic Press Brakes in Modern Manufacturing

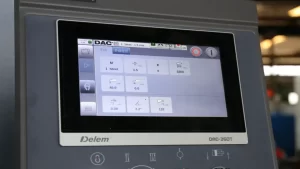

The manufacturing landscape is evolving rapidly with the rise of Industry 4.0. Smart factories demand higher efficiency, precision, and flexibility in production processes. One of the key enablers of this transformation is the Robotic Press Brake. By integrating robotic arms with Листогибочные прессы с ЧПУ, factories can achieve seamless automation, reduce dependency on skilled operators, and optimize the production of sheet metal components.

In a modern smart factory, robotic press brakes not only enhance throughput but also ensure consistent quality across batches, making them indispensable for companies aiming to stay competitive in global markets.

High-Mix, Low-Volume Production: Flexibility in Sheet Metal Bending Challenges in Traditional Press Brake Operations

Challenges in Traditional Press Brake Operations

Conventional press brake operations often struggle to handle high-mix, low-volume production. Manual operations require skilled workers to switch dies, adjust angles, and manage complex bending sequences. This process is time-consuming and prone to inconsistencies, especially when dealing with short production runs or frequent design changes.

How Robotic Press Brakes Solve These Challenges

Robotic press brakes provide flexible automation that can adapt quickly to varying product designs. Features include:

- Automatic part loading and unloading

- Rapid die and angle adjustments

- Precision bending sequences managed through CNC programming

These capabilities allow factories to maintain consistent quality while reducing setup times and operator dependency.

Real-World Applications

Industries like automotive, electronics, and precision sheet metal fabrication frequently rely on robotic press brakes for custom or small-batch components. With a robotic press brake, manufacturers can efficiently produce parts that would otherwise be too labor-intensive or costly to bend manually.

Unmanned / Night-Shift Operations: Maximizing Productivity

Labor Shortage Solutions

Skilled labor shortages are a growing concern in manufacturing. Robotic press brakes enable unmanned operations, allowing factories to maintain production without relying on a full staff of operators. This is particularly beneficial for night shifts or extended production runs.

Continuous Production Benefits

By automating repetitive bending tasks, factories can achieve 24/7 production, maximizing equipment utilization and throughput. This continuous operation also reduces the risk of errors caused by fatigue or inconsistent manual handling.

Integration with Factory Systems

Robotic press brakes can be integrated with MES (Manufacturing Execution Systems) and ERP software, ensuring seamless workflow management, real-time production tracking, and data-driven process optimization. This level of integration is a hallmark of Industry 4.0 smart factories.

Handling Large or High-Strength Sheet Metal

Limitations of Manual or Semi-Automatic Press Brakes

Large or high-strength sheet metal presents significant challenges for traditional press brakes. Manual operations can result in uneven bends, excessive rework, and higher risks of operator injury due to the heavy or rigid materials.

Robotic Press Brake Advantages

Robotic press brakes provide precise positioning, consistent pressure application, and automated handling, making it possible to bend large or high-strength sheets safely and accurately. Robotic arms can handle heavy panels and complex angles with minimal human intervention, ensuring uniformity and reducing waste.

Application Examples

Industries such as aerospace, industrial machinery, and large-scale HVAC or enclosures frequently leverage robotic press brakes for large or high-strength components, improving both efficiency and workplace safety.

Integration with Laser Cutting and Material Handling Systems

Automated Material Flow

Modern smart factories often integrate robotic press brakes with upstream and downstream processes. For instance, material can be automatically transferred from a laser cutting machine to the press brake, eliminating manual handling and reducing lead time.

End-to-End Smart Manufacturing

A fully integrated production line might include laser cutting → robotic press brake bending → assembly or storage, all coordinated via digital control systems. This creates a flexible, responsive production environment capable of handling diverse orders with minimal downtime.

Benefits for Factory 4.0

Integrating robotic press brakes within an automated material flow system enhances traceability, quality control, and process optimization. Factories can monitor every part in real time, identify deviations, and continuously improve production efficiency—key objectives of Industry 4.0.

Key Benefits Across All Applications

Robotic press brakes deliver measurable advantages across multiple applications:

Increased Production Efficiency – Automated operations reduce cycle time and improve throughput.

Reduced Labor Costs – Fewer skilled operators are required, and night-shift automation increases equipment utilization.

Improved Product Consistency – CNC-controlled robotic bending ensures uniformity across all parts.

Enhanced Flexibility – Handles complex geometries, small-batch orders, and high-mix production efficiently.

Smart Factory Integration – Supports MES, ERP, and IoT connectivity for real-time data tracking.

By adopting robotic press brakes, manufacturers can future-proof their operations, reduce costs, and scale production without compromising quality.

Conclusion: Future-Proofing Your Sheet Metal Operations

As Industry 4.0 continues to shape manufacturing, robotic press brakes are becoming essential tools for smart factories. They combine the precision of CNC press brakes with the flexibility and efficiency of robotic automation, enabling high-mix, low-volume production, night-shift operation, and safe handling of large or high-strength materials.

Looking ahead, trends like AI-assisted bending optimization, digital twin integration, and predictive maintenance will further enhance the capabilities of robotic press brakes, making them a cornerstone of next-generation sheet metal fabrication.

Investing in robotic press brakes today positions factories to maximize efficiency, reduce costs, and stay competitive in the increasingly automated world of Industry 4.0.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

Q1: What is a robotic press brake and how does it work?

A: A robotic press brake combines a CNC press brake with a robotic arm to automate bending operations, handle parts, and ensure consistent quality.

Q2: Which factories benefit most from robotic press brakes?

A: Factories producing high-mix, low-volume orders, large or high-strength sheet metal, or those aiming for 24/7 automated production benefit the most.

Q3: How do robotic press brakes improve production efficiency?

A: By automating part handling, reducing setup time, minimizing errors, and enabling continuous operation without human intervention.

Q4: Can robotic press brakes integrate with other Industry 4.0 systems?

A: Yes, they can connect with MES, ERP, and IoT platforms, allowing real-time tracking, data-driven process optimization, and smart factory integration.