How to choose the suitable press brake toolings

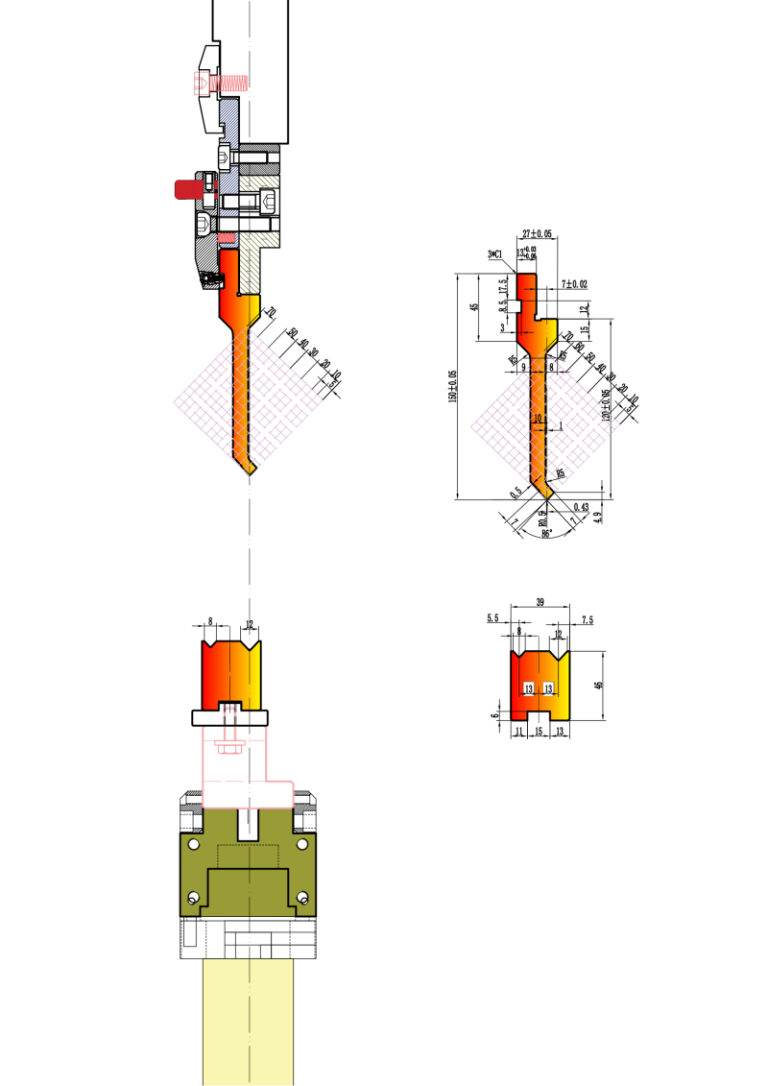

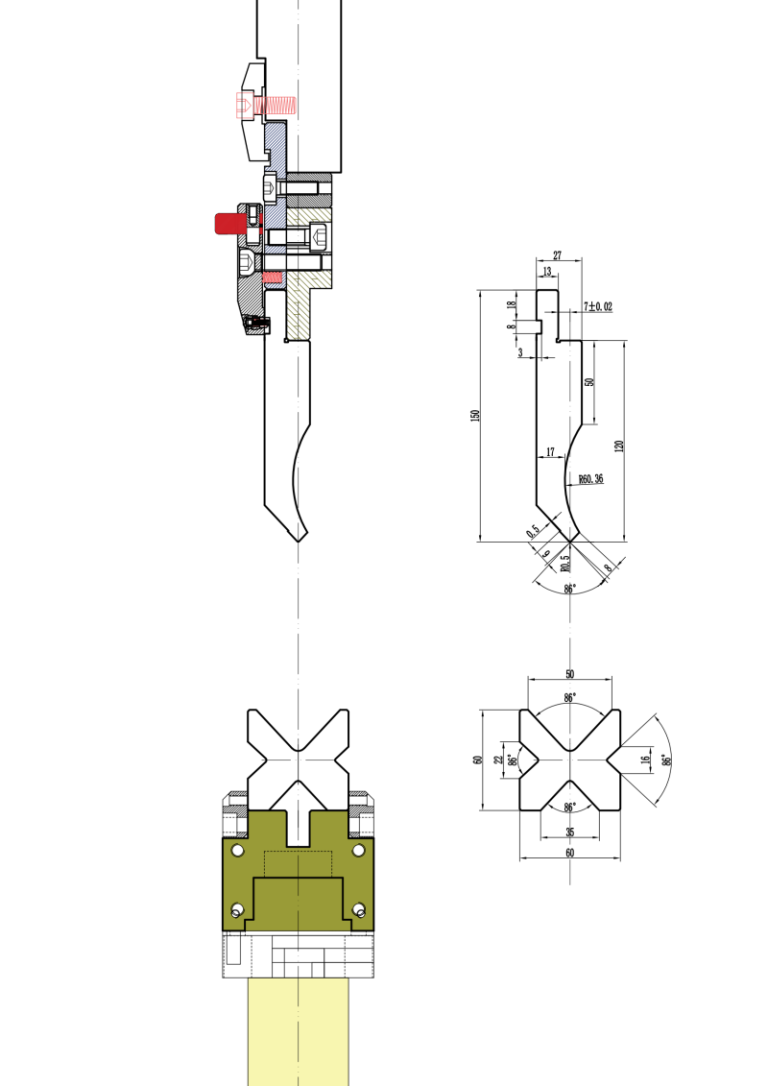

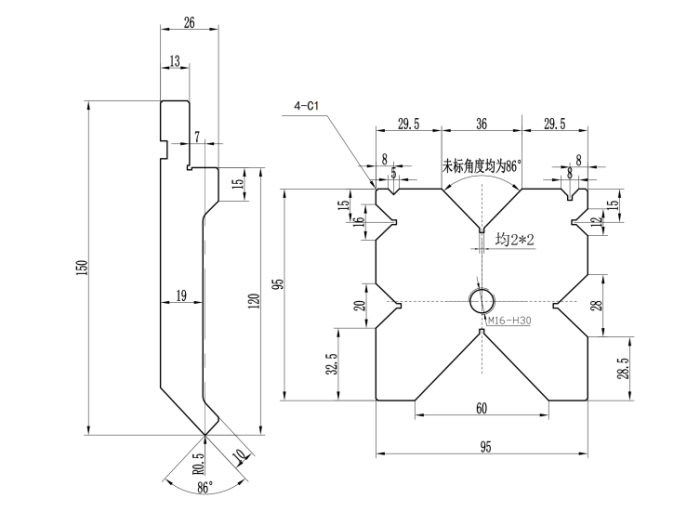

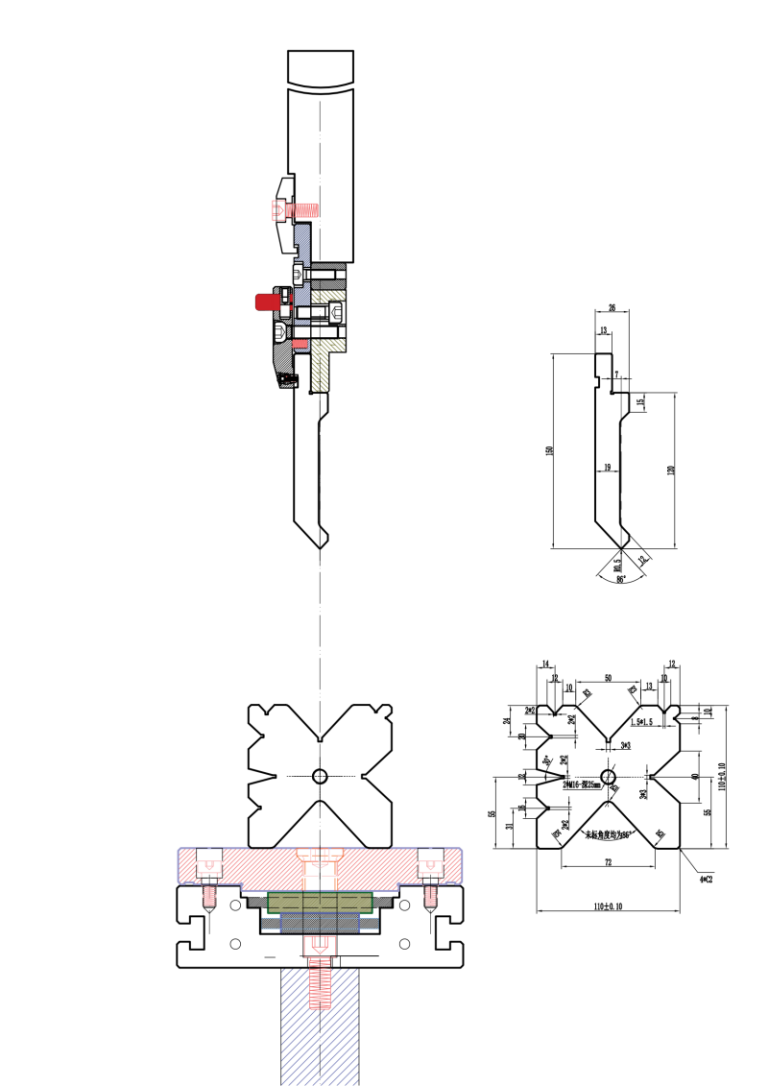

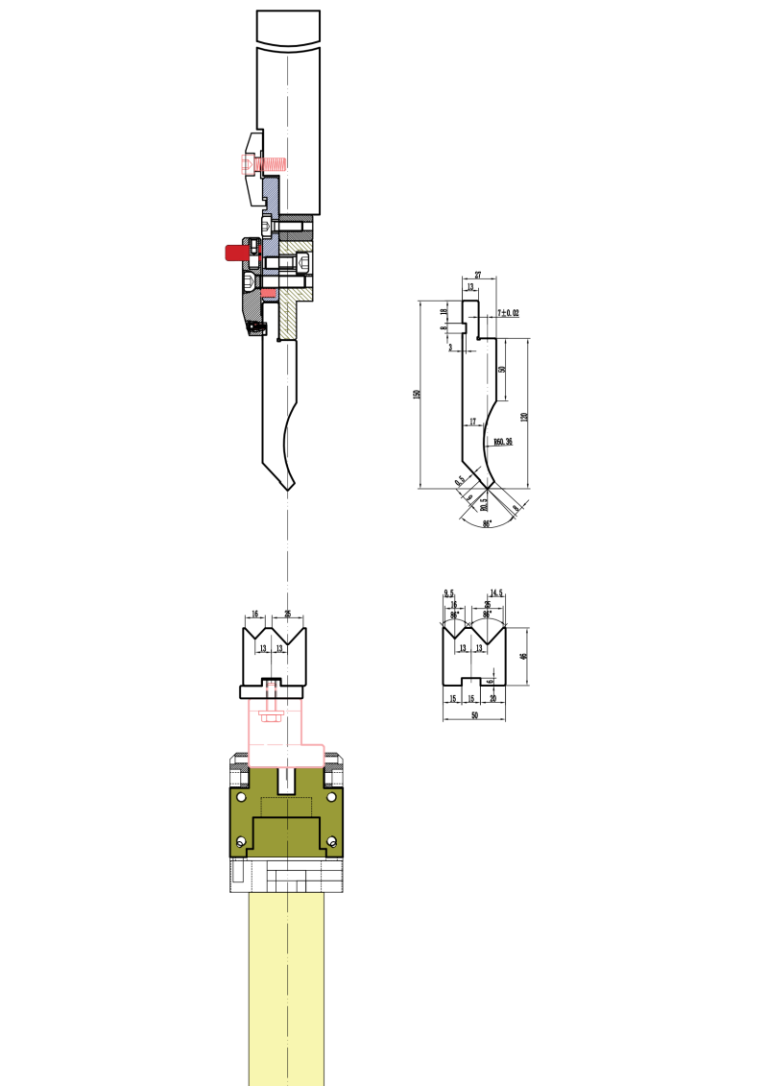

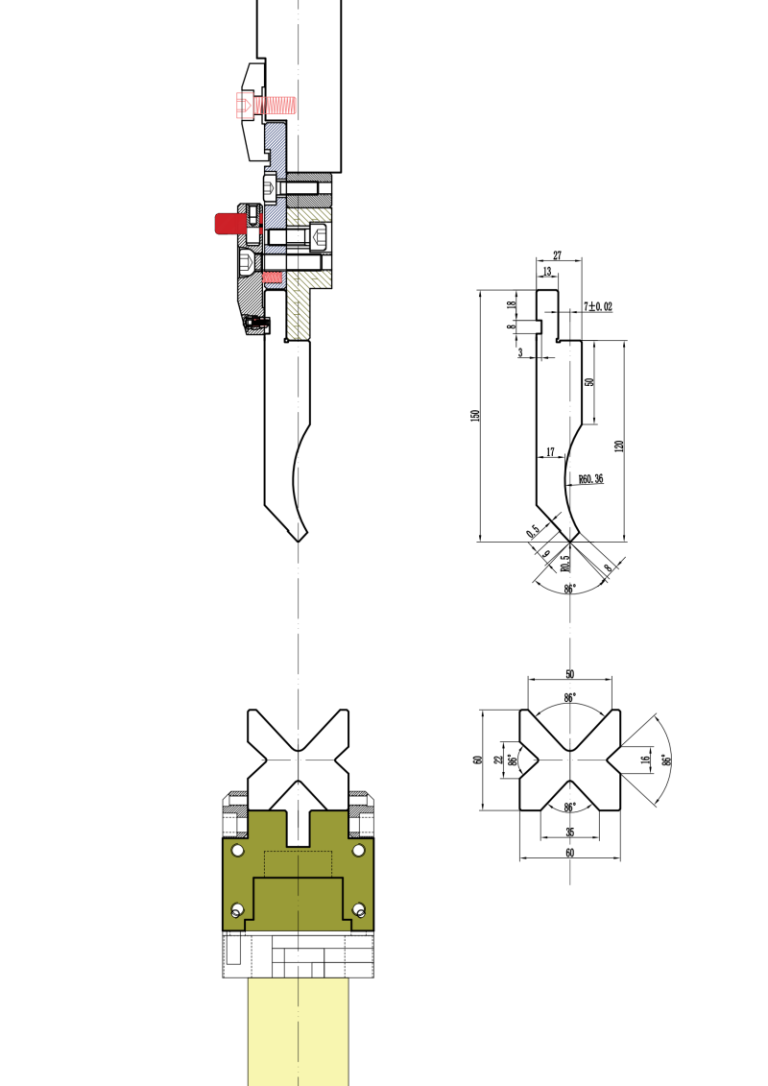

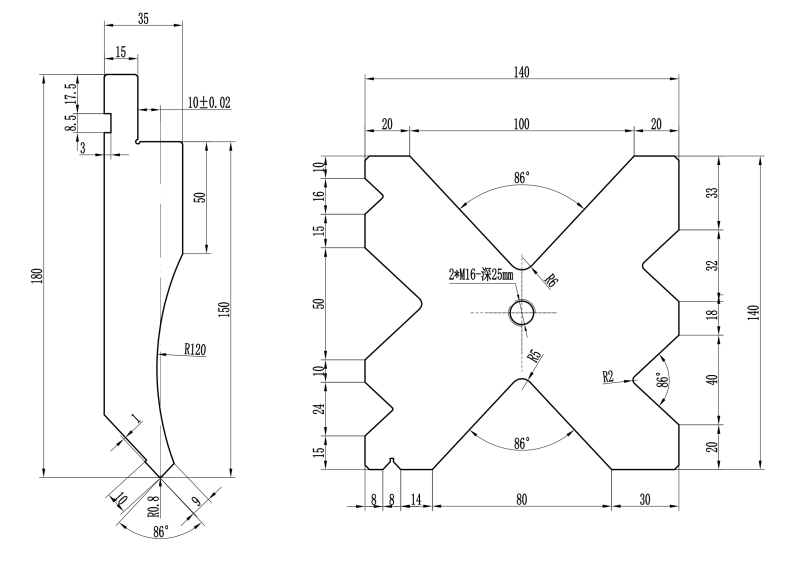

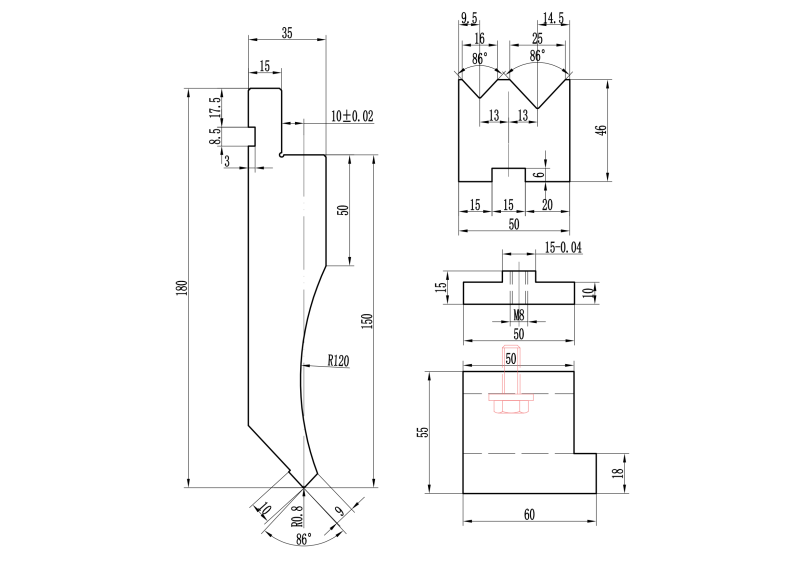

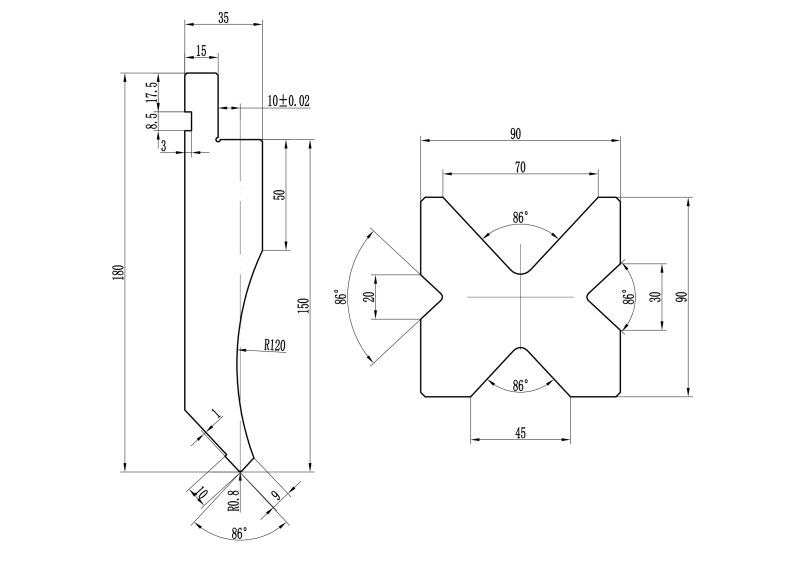

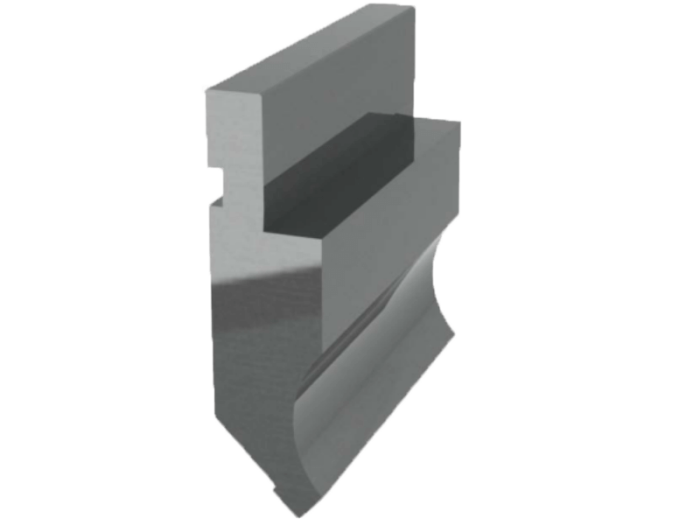

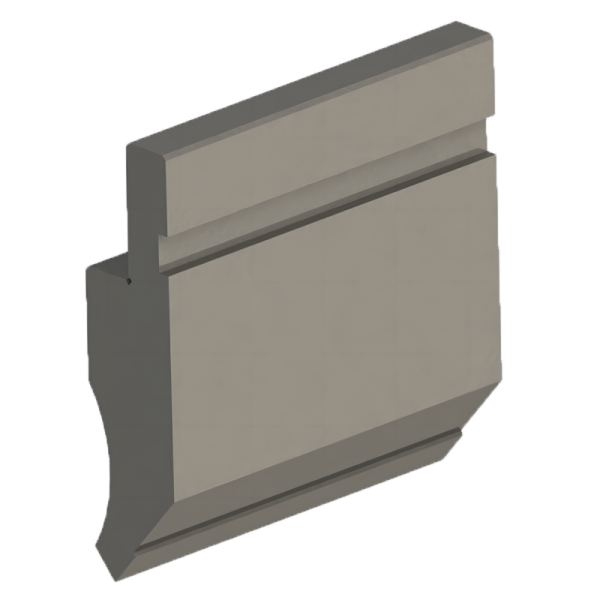

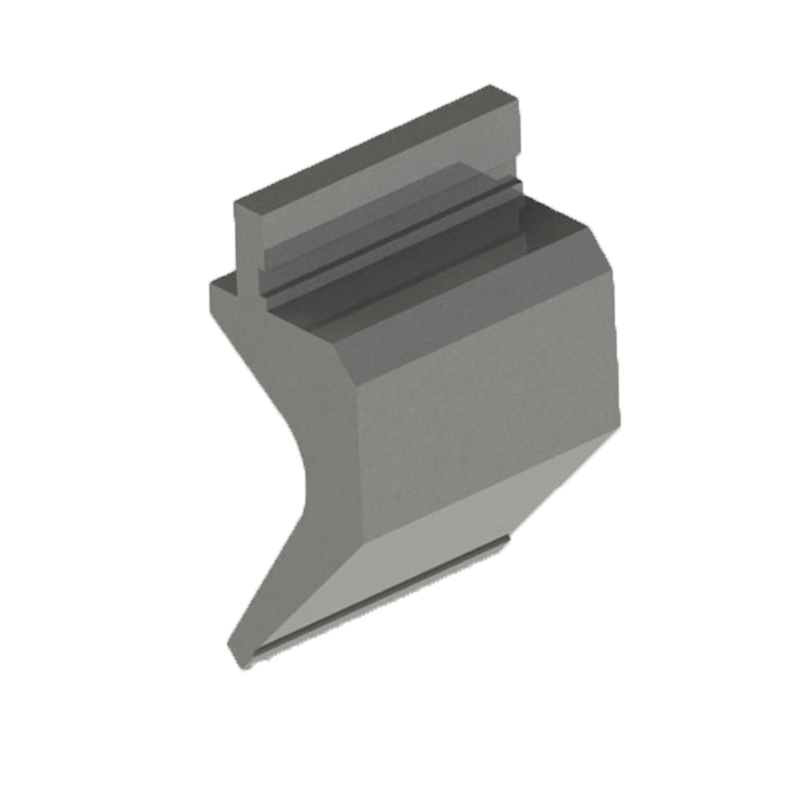

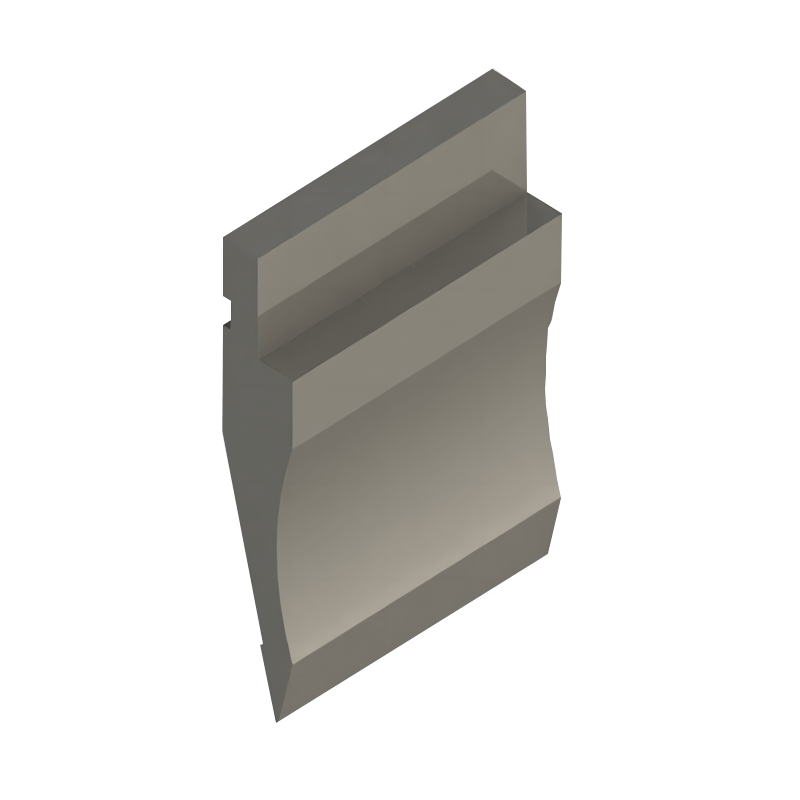

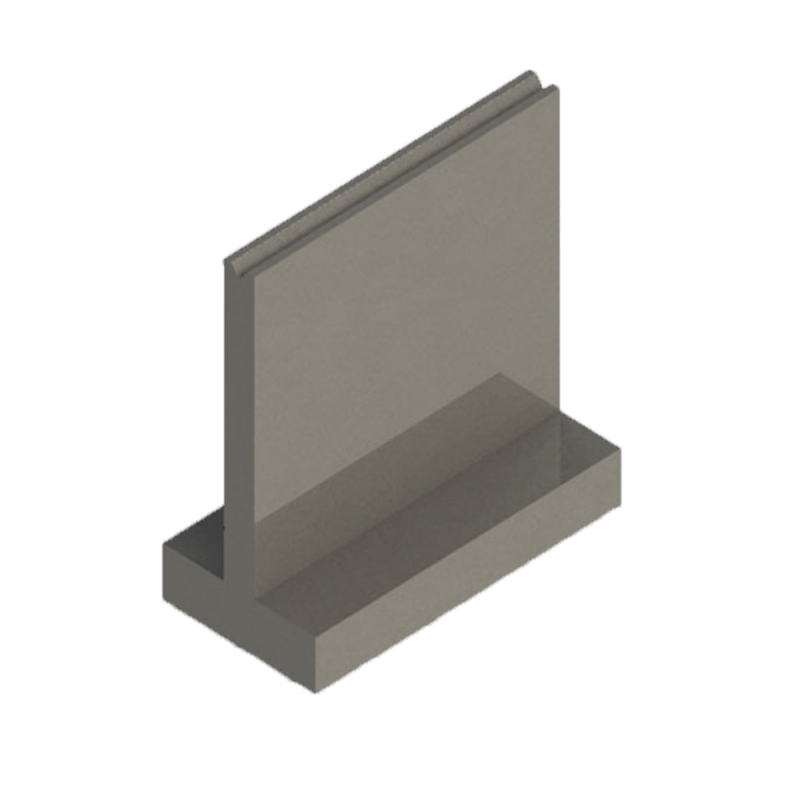

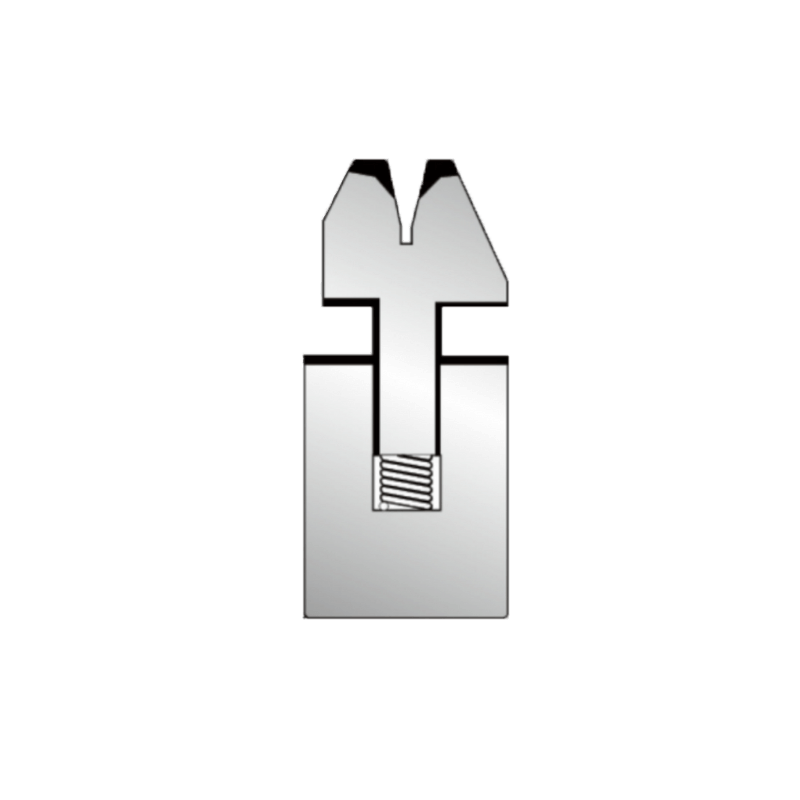

When you choose to purchase our series of press brake machines, we offer you the option to select free press brake dies. Depending on the bending force, we provide three types of dies for you to choose from. Our press brake dies include both standard and custom non-standard molds, comprising upper punch and lower die.

DURMAPRESS press brake tooling offers a range of advantages, making it a top choice in the metalworking industry. Crafted with precision and using high-quality materials, Durma's tooling ensures high-precision bending, guaranteeing quality and accuracy in the manufactured parts. Its durability and wear resistance enable it to maintain stable processing quality even under high-intensity use.