Tailored solutions create efficient systems

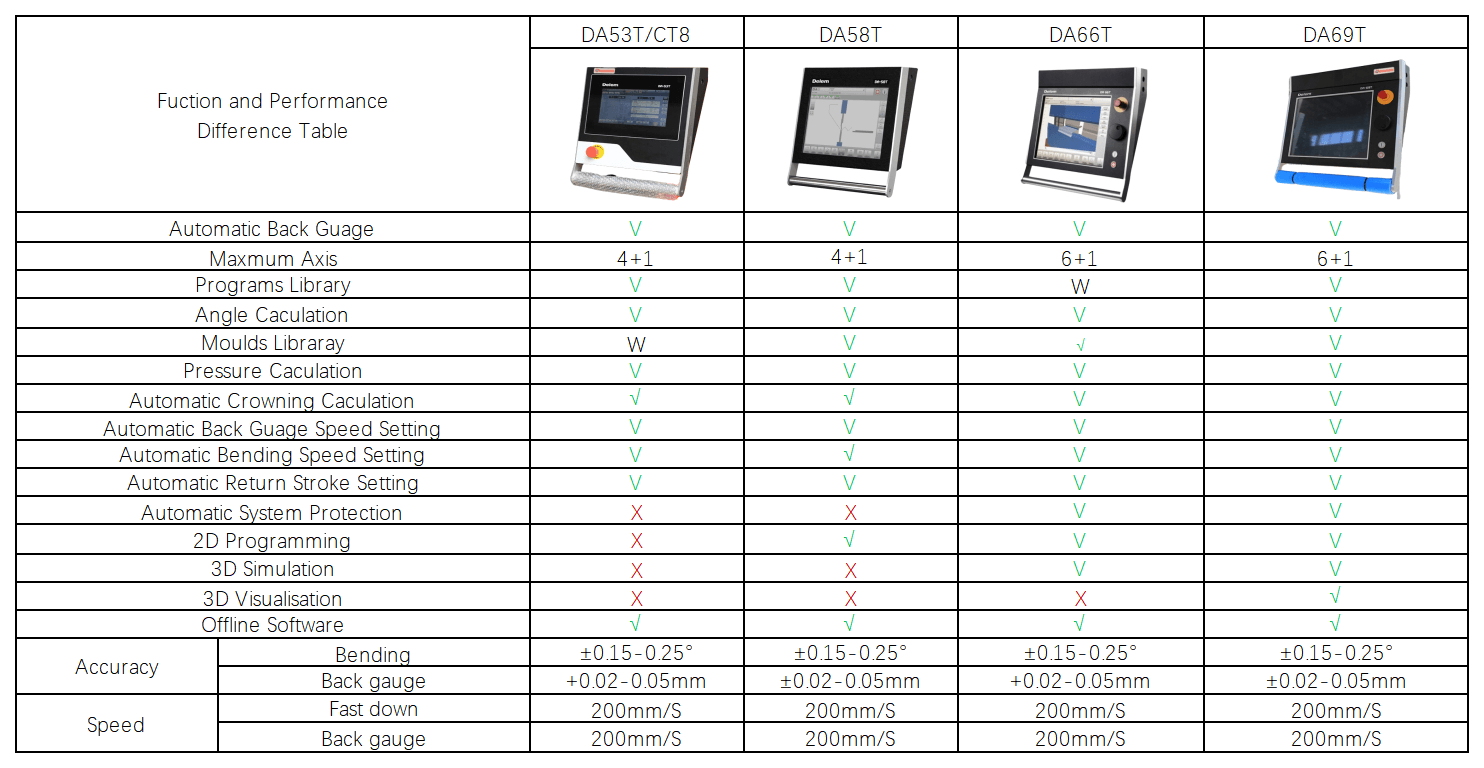

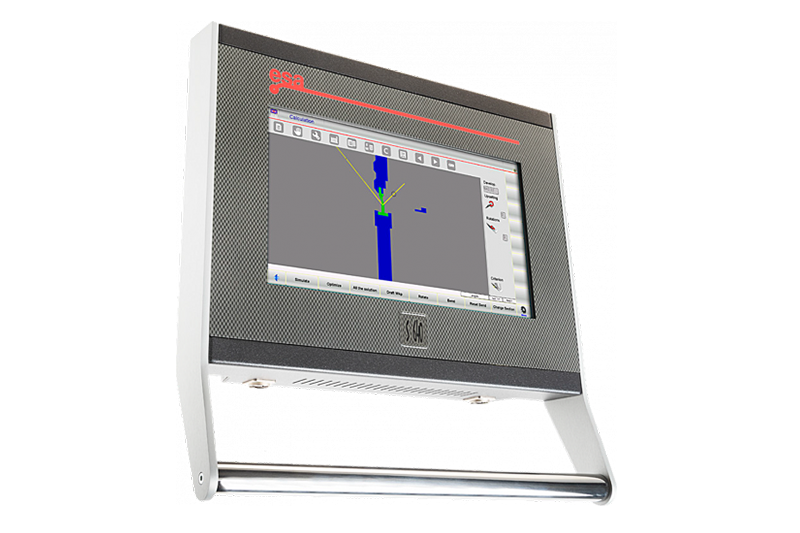

The control solution for press brakes needs to be efficient, tailored, and intuitive for optimal productivity.

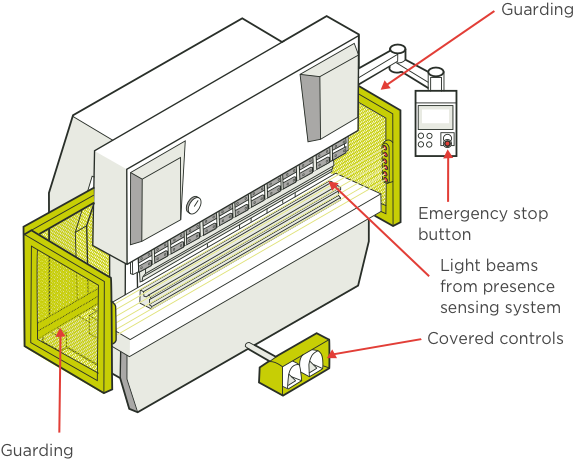

To meet the demands of modern press brake applications, the control solution must seamlessly integrate. Operational efficiency, crucial for maximizing productivity, begins with a control solution tailored to the specific needs of the machine, operator, and tasks at hand. This comprehensive solution instills confidence and enhances productivity.

Our solutions, while diverse, share common features such as operational philosophy, efficient navigation, and parameter resemblance, making them easy to use and navigate. Operators appreciate the proven Delem touch navigation system, which offers long-term functionality and familiarity.