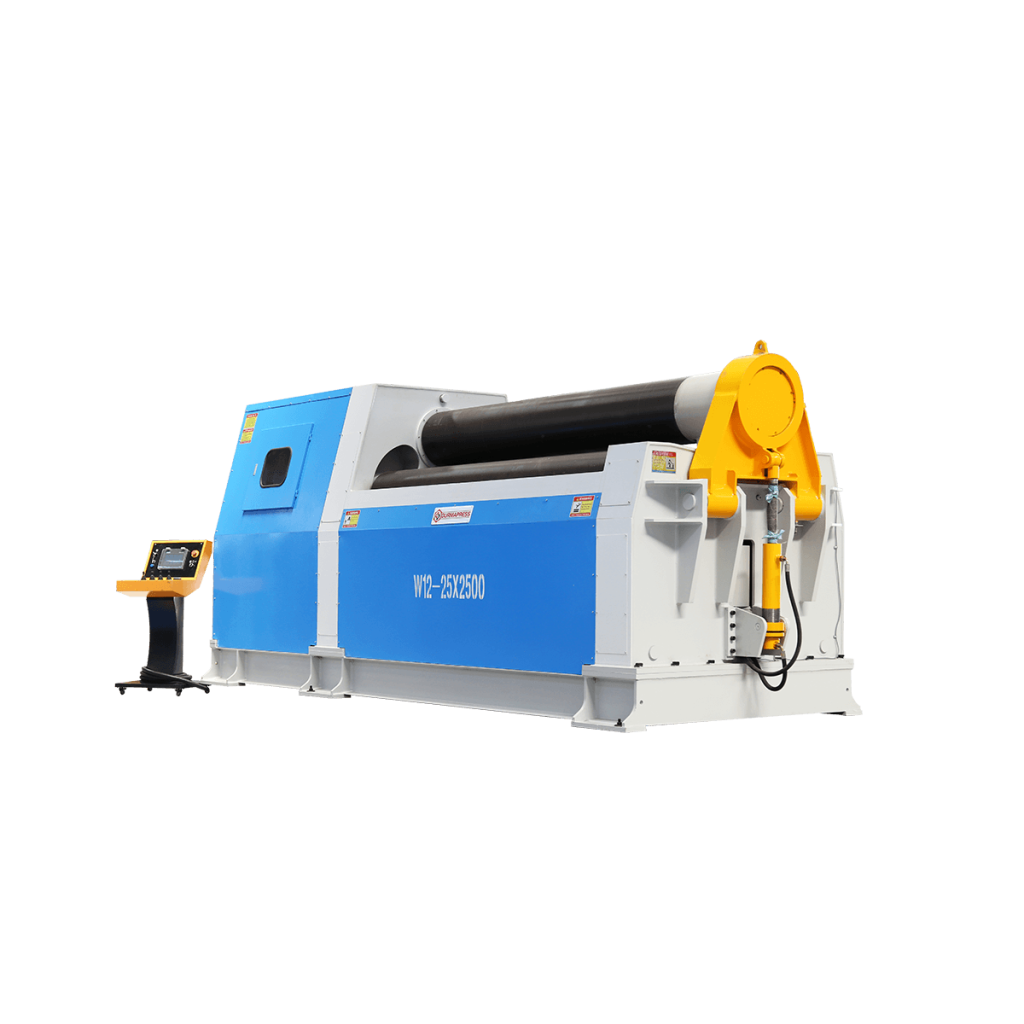

features

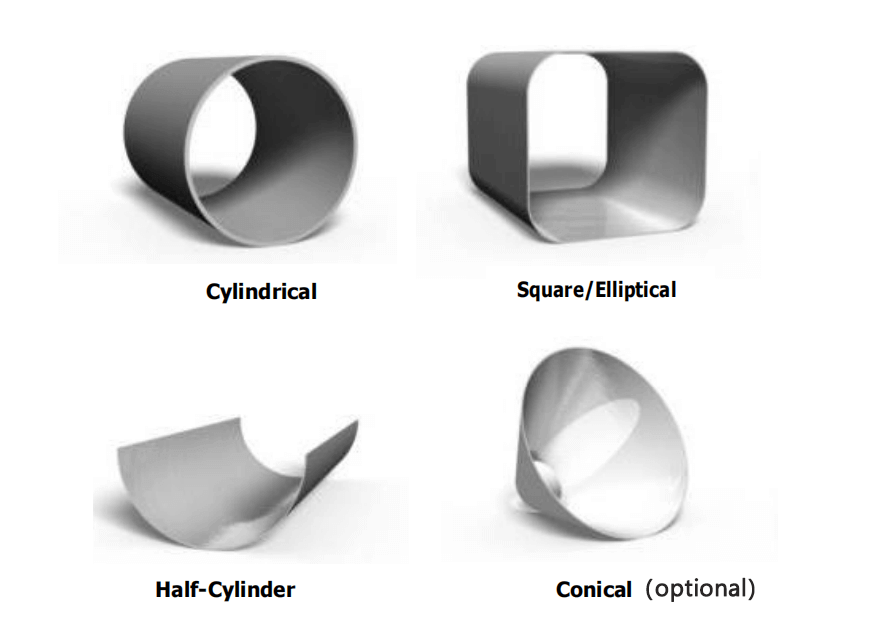

- 4-roller design for bending plates into cylindrical, arc, or cone shapes.

- Has pre-bending function for plate edges and can bend-roll plates in one pass without re-rolling.

- Upper roller is the main drive, while the lower roller and two side rollers are controlled by hydraulic drive.

- Computer-controlled roller displacement ensures high synchronization precision of ±0.2mm for accurate bending.

- Emphasizes one-time finishing of pre-bending and rolling processes, with the top roller driven by a hydraulic motor, bottom roller clamping materials hydraulically, and separate operation of side rollers. PLC NC control and overload protection are included.

durmapress

Standard and optional accessories

Customize your configuration according to your needs

Standard Features

- Induction hardened rolls

- Cone bending device

- Digital display for siderolls

- Fully welded sreel(St-52) construction body

- Separate movng control panel

- Two rolling speeds

- All rolls are mounted in roller spherical roller bearings

- Safety equipment aroumd the machine.

- Central rolls are driven by hydraulic motors and planetary gearboxes

- CE, ISO9001 -2008 certified machine

optional Features

- Central and side supports

- Material feeding table with various features

- Fan cooled or water cooled

- Automatic loading and unloading system

- Safety cable

- Ground and polished rolls for special job

- Top and lateral support rack for big diameter

durmapress

Main Components

Standard accessories for W12 CNC Hydraulic Rolling Machine

body structure

The bodies of DURMAPRESS Plate Rolls are designed with FEM analysis to obtain a maximum strength and rigid structure. In this way, tensions that occur during bending are minimized to provide safer and longer machine life.

4-Roll Planetary Design

In this models, rolls are hardened to 50-60 HRC and crowned to compensate for deflection during rolling. They're polished to DIN Ck45 quality and can be extended for bending different profiles upon request.

control panel

Due to its mobility, the machine controls material rolling from all sides. The digital display on standard machines shows the present and maximum positions of the right and left rolls. The control panel can be customized with additional buttons for preferred optional features.

Linear Guides

The system uses linear guides, ensuring the rolling scales do not affect the system. This planetary system operates safely with minimal maintenance and downtime, maintaining a robust body even at small rolling diameters.

rolling momentum

The hydraulic motors and planetary reducers power the lower and upper rolls, ensuring efficient rolling. The planetary reducer connects directly to the roller shafts, transferring momentum without power loss. A hydraulic stopping brake enhances safety during pre-bending.

electronic part

All rolls are supported by spherical roller bearings, which can carry heavy loads and facilitate conical movements. These bearings operate with high precision and durability, even in challenging conditions. By reducing friction, they save energy, ensuring that the full power is used to shape the material.

optional

Other Components

Top-Quality Accessories from Leading International Brands

Top and lateral support rack

Top and lateral support racks in plate rolling machines provide crucial support by preventing sagging and side deflection of large or thin plates during rolling, thereby enhancing rolling accuracy, improving product quality, and reducing operator effort for smoother, more efficient operation.

Material feeding table

The material feeding table for a plate rolling machine is engineered to enhance efficiency, precision, and safety by incorporating features such as automatic centering, servo-driven alignment, vacuum suction handling, and adjustable configurations to accommodate various plate sizes and shapes.

Why choose us

from start to finish

Durmapress always adheres to the concept of putting customers first in the whole purchase experience, and continuously optimizes and innovates the production process to cater to the needs of all large, medium and small manufacturing companies.

- 20+ Years of Experience

- Personalized customized machines

- Perfect after-sales system

- 24/7 Availability

Get more details

What are Advantages of optional device?

1

Cone bending device

Achieving cone bending with the W12 is straightforward. The bottom rolls are angled to create the cone shape, a process easily controlled and monitored by the electronic microprocessor (available on select models).

Our control system guarantees a precise return to parallel setting after cone bending, ensuring accuracy and consistency in repetitive tasks.

2

Automatic loading and unloading system

Automatic loading and unloading systems offer several key advantages. They increase efficiency by speeding up the process and reduce the risk of injuries associated with manual handling. Additionally, automation ensures consistent and reliable operations, minimizing errors. This technology also saves on labor costs and enhances overall productivity by allowing for continuous operation. Finally, these systems can be designed to optimize space utilization in the work area.

3

Top and lateral support rack for big diameter

The top and lateral support rack for large diameters on a rolling machine provides several advantages. It ensures stability and precision during the rolling process, especially when handling larger and heavier materials. This support system helps prevent deformation and maintains the shape of the workpiece, resulting in high-quality finished products.

4

Fan cooled or water cooled

Fan-cooled or water-cooled systems in rolling machines offer several advantages. They help maintain optimal operating temperatures, preventing overheating and ensuring consistent performance. These cooling systems also help extend the lifespan of the machine components by reducing wear and tear caused by excessive heat.

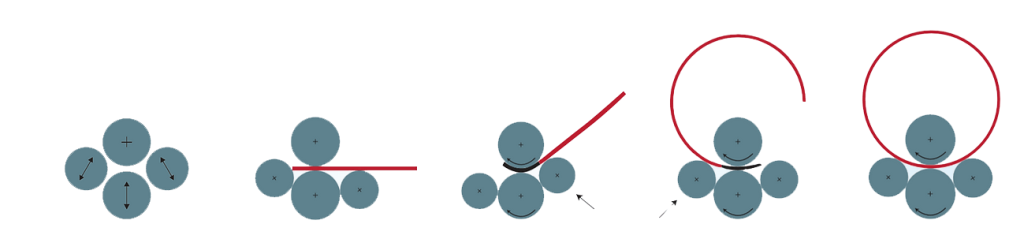

Working Principle

The Feature of the Mechanical Plate Rolling machine

Hydraulic System

Utilizes a variable flow piston pump for high-pressure resistance, durability, and low noise. The specially designed hydraulic motor offers efficient operation with minimal power consumption and increased speed.

Features an integrated hydraulic control system from YUKUN-Japan for reliability and easy maintenance. Includes overload overflow protection for leak-free operation and direct oil level monitoring. Compliant with Directive 98/37 EC.

Electrical System & Safety

The electrical cabinet meets IP65 standards and is CE certified, ensuring safety and reliability with strong anti-interference capabilities. Equipped with protective fences, safety interlocks, and a movable single-hand pedal switch for easy operation.

Front side covers include safety switches, backlight safety guards (Category-4), and a foot pedal conforming to CE regulations for enhanced safety during operation.

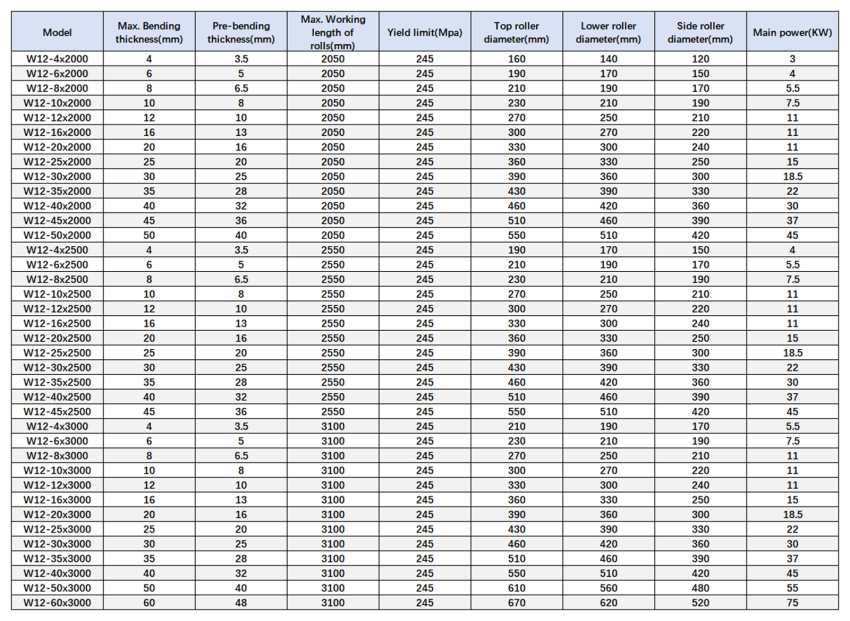

technical parameters

durmapress

common rolling shapes

durmapress factory

Watch the Video

Contact us

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

7/24