RayBox: Helping You Realize Digital Connection Of Industry 4.0

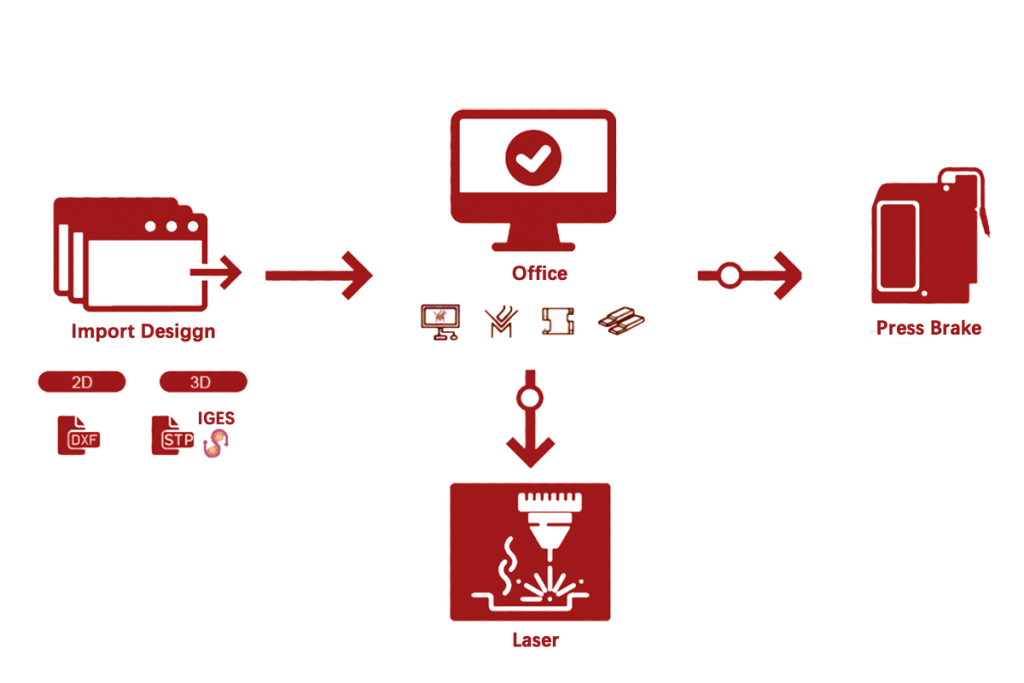

We know that production efficiency is the key to metal processing and manufacturing, so how can we use digital technology to improve production efficiency? Many metal processing factories already have

How-Can-The-MES-System-Eliminate-Inefficiency-In-Automotive-Sheet-Metal-Manufacturing-300x169.jpg)