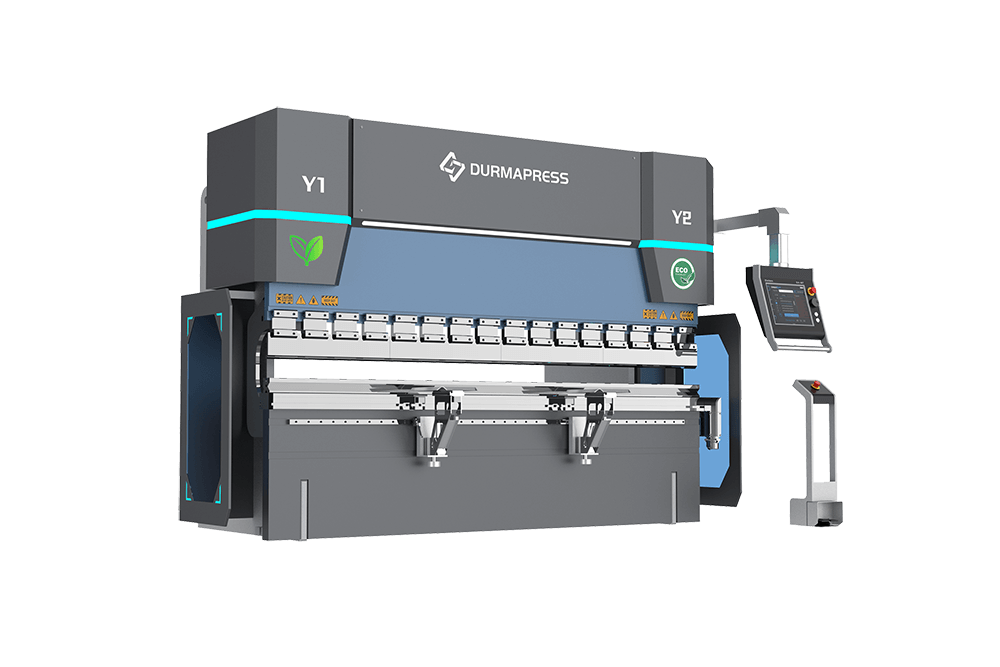

DP-ES pro SERIES

CNC servo Press Brake

The DP-ES pro Series Press Brake 4~6+1 Axis provides reliable precision and versatility for most bending applications. Increase your productivity with this durable and efficient solution.

The DP-ES pro Series Press Brake 4~6+1 Axis provides reliable precision and versatility for most bending applications. Increase your productivity with this durable and efficient solution.

Press Brake Toolings

Toolings Holder

CNC Controller System

Light

Foot Switch

Sheet Front Supporter

Crowning

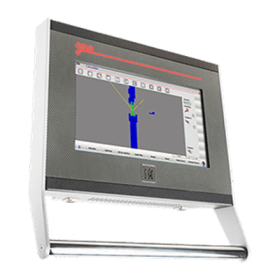

The DA-66T Touch controls feature the embed-ded, real-time Windows operating system for maximum reliability. Smooth start-ups ensured, even after instant shut-off.

Customize The Controller For Your DP-ES PRO Series

High-performance CNC for machines up to 6 axes with a 15” ultra-sharp TFT LCD color screen and intuitive HMI for an enhanced user experience.

The industrial PC with Intel quad-core CPU and Windows 10 ensures superior performance and versatility.

The CybTouch 12 offers an intuitive touchscreen with large keys, user-friendly software, and automatic functions, blending power with simplicity.

Every part can ensure a long service life and reduce production costs.

Durmapress press brakes feature a robust mono-block frame made from high yield steel, ensuring enduring accuracy and reliability. Each frame is tempered and backed by a 15-year warranty.

Certainly, the controller functions as the central intelligence of the complete machinery. Our firm delivers top-notch controllers sourced from esteemed brands like Delem, ESA, and Cybelec.

We use Taiwan PMI ball screw and linear guide for X-axis precision, ensuring higher accuracy than rod-based systems. The backgauge controlled by a servo motor with a timing belt & wheel mechanism, offers precise positioning.

We use the Siemens energy-efficient motor from Germany, designed to meet the daily production demands of our clientele seamlessly. This motor operates substantially more efficiently than standard motors.

Harnessing the reliability of genuine Schneider components sourced directly from France, renowned for their unwavering stability, impressive durability, and prolonged lifespan.

It ensures consistent processing position and size by precisely controlling the workpiece stop. The adjustable Stopper Finger position and height accommodate various workpiece sizes and shapes.

Durmapress's self-developed Side Fast Clamp can be used with various series to complete bending work including heavy machines. The tooling replacement is smooth and durable.

The durable front supporter ensures long-lasting stability and precise positioning, reducing workpiece deformation and enhancing processing accuracy.

Top-Quality Accessories from Leading International Brands

Ensures precise, consistent bend angles across the workpiece, compensating for die deflection to reduce scrap and boost efficiency.

The European Type Sectioned 4V Die & Punch offers versatile bending, quick setup, and high precision for enhanced press brake performance.

Experience unparalleled precision with the iMeasure Laser angle measurement system in collaboration with Data-M Engineering, ensuring accurate bend angles with just one operation.

The DSP Laser Protection system monitors the intensity and location of laser radiation in real time to ensure that any possible laser safety hazards can be detected in time when the press brake is running.

The latest followers for sheet metal bending aim to optimize the performances of our press brakes by reducing the time to set up the press brake and simplifying the work of operators. These bending aids provide operators with valuable practical assistance.

We use WILA's innovative technologies, including Safety-Click®, Smart Tool Locator® and the E2M® replacement system for (heavy-duty) tools, to enhance the safety and convenience of replacement. Precision and ergonomics are carefully tailored for maximum productivity from all tools.

Get more details about DURMAPRESS®’s DP-ES PRO SERIES CNC Servo Press Brake

Our hydraulic cylinders are made of high-quality alloy steel for durability and reliability.

1

DP-ES Pro Servo introduce a cost-effective compact CNC press brake that offers a myriad of features and options.

2

Experience competitive pricing paired with cutting-edge DELEM DA53T 2D graphical controls or Cybelec CybTouch 8PS.

3

The DP-ES Pro Servo Series stands out as the top choice for Y1/Y2 machine technology.

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

7/24

Fill in the information below to receive a free quote and product brochure. We will respond within 24 hours!