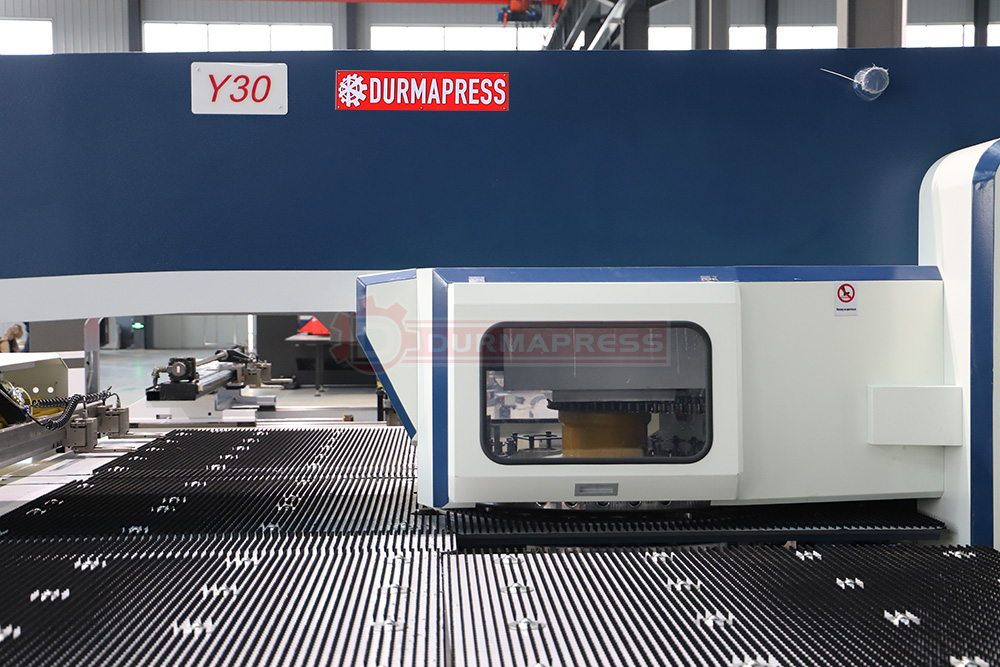

CNC Turret Punch Machine

General Features

Can realize various processes such as punching, forming,

rolling, lettering, etc.

All-electric servo intelligent punch headGermany Rexroth guide screw

German Rexroth CNC system

The perfect CNC turret punching machine

The servo motor direct drive main drive is adopted, which retains the advantages of simple, mature and reliable mechanical main drive structure. At the same time, it has better characteristics than hydraulic main drive, with remarkable features and powerful functions.

1. Various processes such as punching, forming, rolling and lettering can be realized

2, all-electric servo intelligent striking head

3, Germany Litu Le guide screw

4, German Rexroth CNC system

Components

Standard equipment:

- High speed servo-controlled punching head

- 6 axis CNC TPC69T Graphics touch screen control with graphical programming

- 4 Repositioning cylinders (2 upper, 2 lower)

- 3 Hydraulic sheet clamps

- 4 Vibration dampers

- 12 or 20 tool stations complete with tool holders

- Slug suction device

- Part chute door 300x470mm

- Quick tool set for tool alignment

- CE optical safety light

- Automatic oil spray machine

- CE certified machine

Main Components

Machine Body

The body adopt integrated fuselage, widened design, disposable welding, tempering, disposable forming.

Durmapress Controller (Optional Siemens)

The system can automatically search, to select the most suitable tool to processing, and display stamping time, processing capacity, die life (punches), etc.

Ball Screw & Linear

Carriage and beam integrated design, accurate positioning, moving more smoothly, to eliminate the X, Y-axis dynamic offset case.

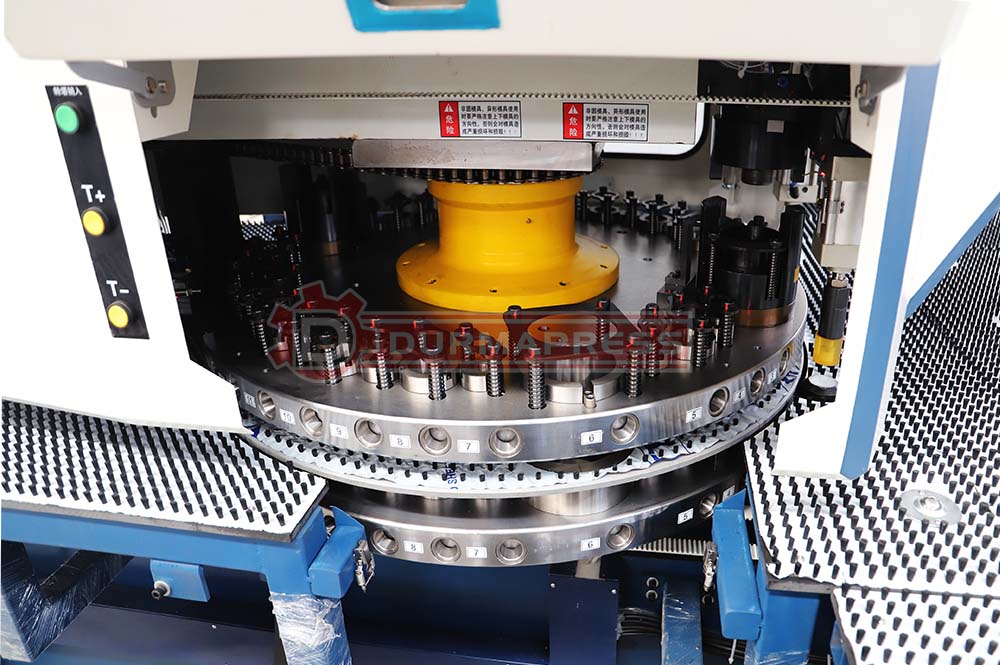

Turret Structure

The turret is made of 40Cr, completed in large processing center; using Germany mosaic roulette.

Seamless Worktable

Seamless worktable design, when the plate moved, it can avoid the plate and the worktable make a collision, guide rail, ball screw dust-proof protection.

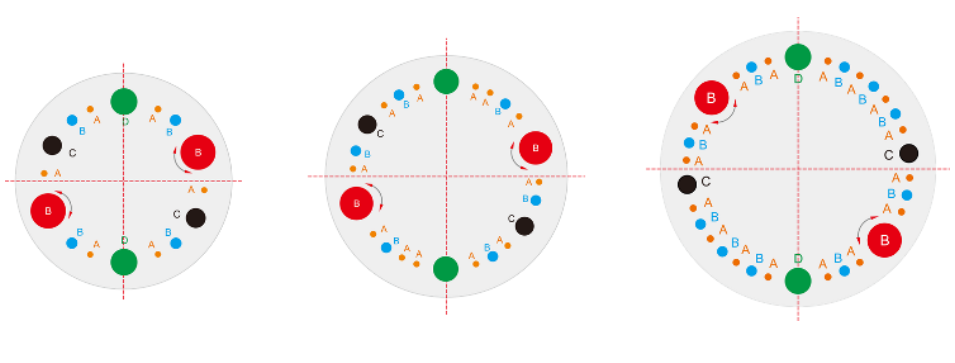

Layout

| Station | Tool size | 16 stations | 24 Stations | 32 Stations |

|---|---|---|---|---|

| A | Φ1.5 - Φ12.7 | 6 | 12 | 16 |

| B | Φ12.7 - Φ31.7 | 6 | 8 | 12 |

| C | Φ31.7 - Φ50.8 | 2 | 2 | 2 |

| D | Φ50.8 - Φ88.9 | 2 | 2 | 2 |

Product Introduction Video

CNC Turret Punching Machine

This machine is reliable and effective. The parallelism of the side rolls is controlled by a torsion bar system that connects to both ends of the side roll, eliminating the disadvantage of extra encoders and special hydraulic balancing valves. The two central rolls are driven by hydraulic motors and high efficiency planetary gearboxes coupled directly on the rolls. The MG solution, with rolls assembled on sealed bearings and without secondary components, reduces the dispersions of the applied force generated by the frictions of the various components (typical in synchronization systems used in other bending machines).

| NO. | Name | Unit | Specification |

|---|---|---|---|

| 1 | Press Capacity | Tons | 30 |

| 2 | Frame Construction | O-Frame | |

| 3 | Max. Sheet Size (with one reposition) | mm | 1500x5000 |

| 4 | Max. Sheet Thickness | mm | <6 |

| 5 | Max. Hole Diameter | mm | Φ88.9 |

| 6 | Stroke | mm | 40 |

| 7 | Max. Hit Rate | hpm | 280 (30mm pitch) |

| 8 | Max. Feed Rate | m/min | 80 |

| 9 | Clamps No. | pcs | 3 |

| 10 | Re-positioning Cylinder | set | 2 |

| 11 | No. of Stations | pcs | 16 (6A/6B/2C/2D ) |

| 12 | Turret Rotating Speed | rpm | 30 |

| 13 | Turret Positioning | Double cylinder positioning | |

| 14 | Air Pressure | mpa | 0.6 |

| 15 | Die Form | Mosaic turret, Long guide tool | |

| 16 | Punching Accuracy | mm | ±0.10 |

| 17 | No. of Controlling Axis | pcs | 3(X/Y/T) |

| 18 | Total Power | kw | 14 |

| 19 | Average Power Consumption | kwh | <2 |