Request Information

Contact Information

Headquarters

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Phone/ Whatsapp

+86 183 2557 2889

No Oil. No Noise. Just Pure Performance.

Trusted by 5000+ manufacturers worldwide

Our all-electric press brakes represent the pinnacle of metal forming technology, combining precision engineering with sustainable operation.

Engineered for precision, efficiency, and reliability in modern manufacturing environments

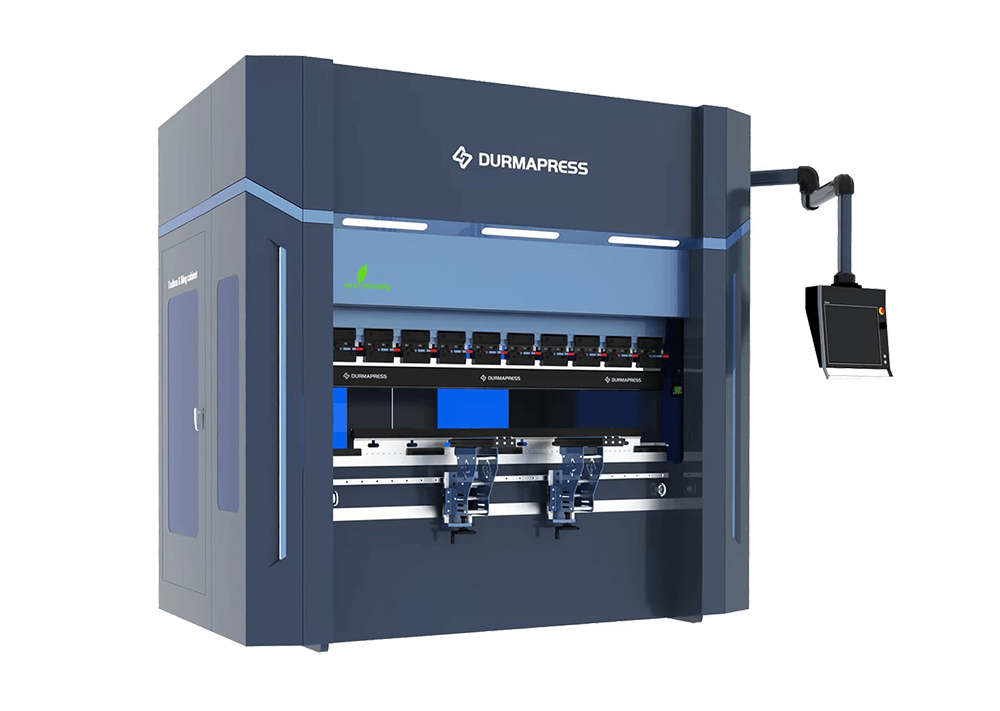

The DURMAPRESS All-Electric Press Brake represents the next generation of metal forming equipment, delivering unmatched precision while eliminating the environmental concerns associated with traditional hydraulic systems.

Equipped with the industry-leading Delem DA-66S/69S control system featuring:

Engineered to deliver exceptional performance across a range of manufacturing requirements

For complete technical specifications and custom configuration options

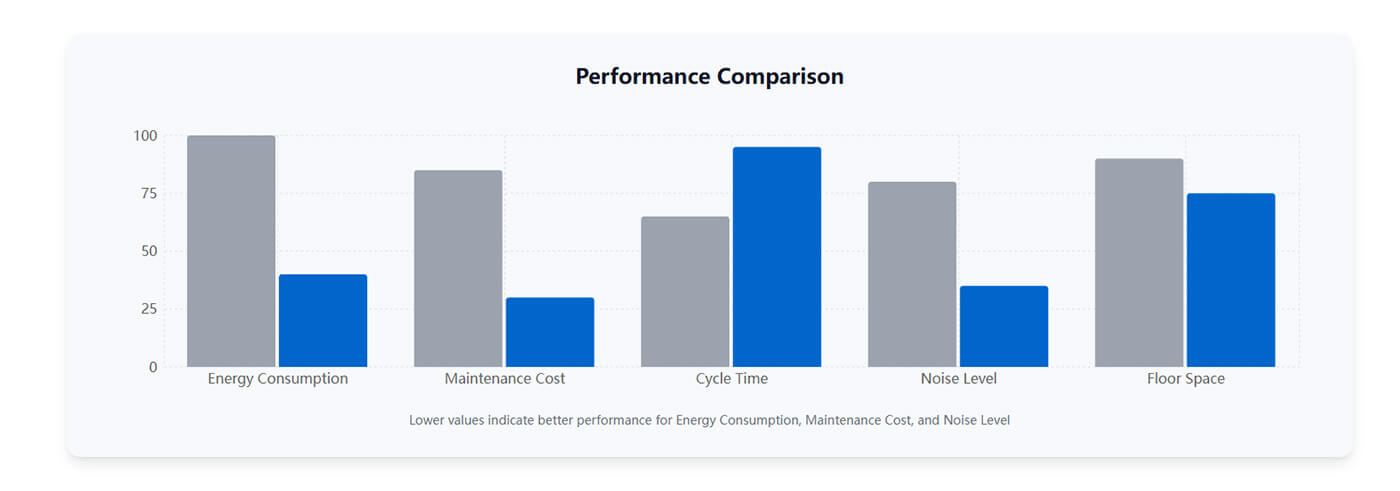

Comparing traditional hydraulic press brakes with modern all-electric technology

Use our bending force calculator to get precise press brake pressure results for any material and tooling setup.

Ensuring precision and durability across all metal forming applications.

Watch the DURMAPRESS All-Electric Press Brake demonstrate its precision and efficiency

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

+86 183 2557 2889

Fill in the information below to receive a free quote and product brochure. We will respond within 24 hours!