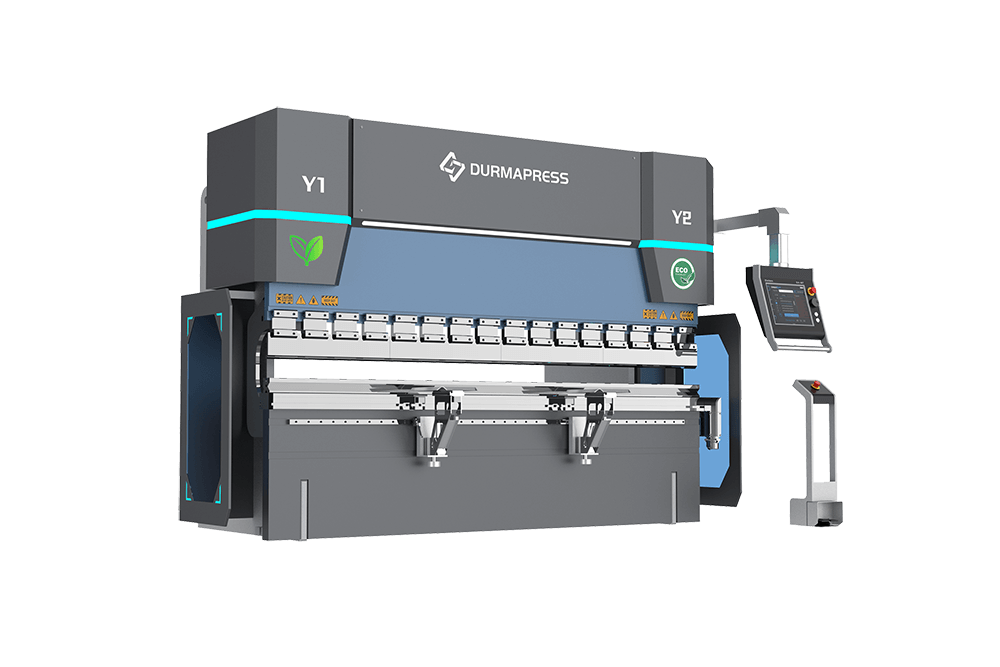

CNC servo Press Brake

The DP-ES pro Series Press Brake 4~6+1 Axis provides reliable precision and versatility for most bending applications. Increase your productivity with this durable and efficient solution.

Trusted by 5000+ manufacturers worldwide

Product Overview

Engineered for precision, efficiency, and reliability in modern manufacturing environments

Revolutionary Bending Technology

The DURMAPRESS CNC press brake machines are designed for precision, durability, and efficiency, providing the perfect solution for your metal fabrication needs.

Advanced Technical Features

- Achieve high-accuracy bending with a durable, stress-relieved frame that ensures long-term stability.

- Enhanced throat depth, stroke, and daylight expand the machine’s performance range for more demanding applications.

- An innovative structural design delivers stronger, faster operation with reduced noise.

- Quick tooling changes and precise alignment improve workflow efficiency while lowering overall production costs.

- Globally sourced components and a simplified maintenance layout further ensure reliability and user convenience.

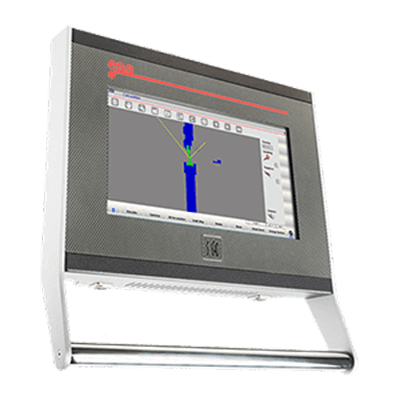

Intuitive Control System

Touch controls feature the embed-ded, real-time Windows operating system for maximum reliability featuring:

- 2D graphical touch-screen programming supported by an 18.5" high-resolution color TFT

- Automatic bend-sequence calculation and crowning control

- Servo and frequency-inverter control, paired with advanced Y-axis algorithms

- USB and peripheral interfacing enables flexible connectivity and easy data handling.

- Profile-T offline software enhances productivity with efficient offline programming and job preparation.

Press Brakes CNC Control System

Customize The Controller For Your DP-ES PRO Series

ESA S640

High-performance CNC for machines up to 6 axes with a 15” ultra-sharp TFT LCD color screen and intuitive HMI for an enhanced user experience.

ESA S650

The industrial PC with Intel quad-core CPU and Windows 10 ensures superior performance and versatility.

CybTouch 12

The CybTouch 12 offers an intuitive touchscreen with large keys, user-friendly software, and automatic functions, blending power with simplicity.

Detailed Design & Components

Explore the precision engineering behind our press brake systems

Frame & Base Structure

Durmapress press brakes feature a robust mono-block frame made from high yield steel, ensuring enduring accuracy and reliability. Each frame is tempered and backed by a 15-year warranty.

Backguage

We use Taiwan PMI ball screw and linear guide for X-axis precision, ensuring higher accuracy than rod-based systems. The backgauge controlled by a servo motor with a timing belt & wheel mechanism, offers precise positioning.

CNC control System

Certainly, the controller functions as the central intelligence of the complete machinery. Our firm delivers top-notch controllers sourced from esteemed brands like Delem, ESA, and Cybelec.

Stopper Finger

It ensures consistent processing position and size by precisely controlling the workpiece stop. The adjustable Stopper Finger position and height accommodate various workpiece sizes and shapes.

Front Supporter

The durable front supporter ensures long-lasting stability and precise positioning, reducing workpiece deformation and enhancing processing accuracy.

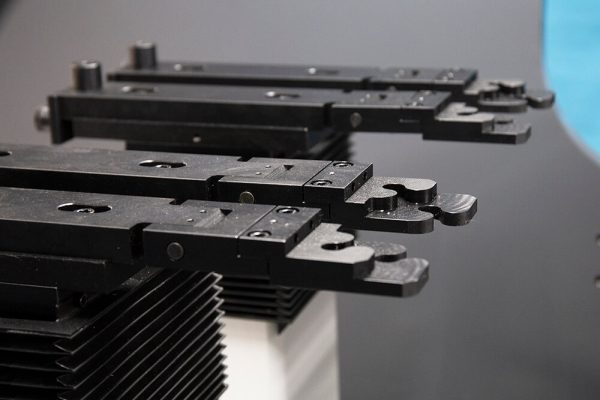

Fast Clamping

Durmapress's self-developed Side Fast Clamp can be used with various series to complete bending work including heavy machines. The tooling replacement is smooth and durable.

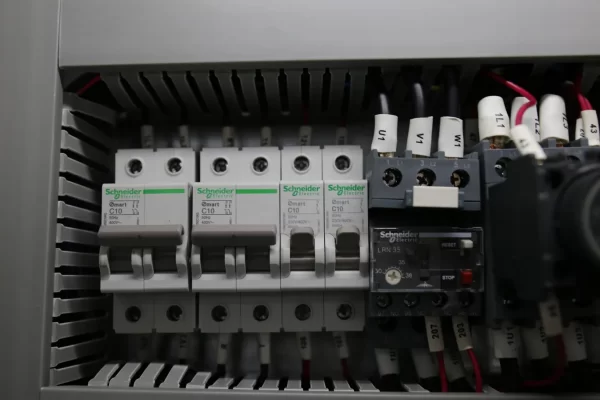

Schneider® Electrical Part

Schneider® electrical parts provide reliable power control, industrial-grade safety, and stable performance as standard components on our press brakes.

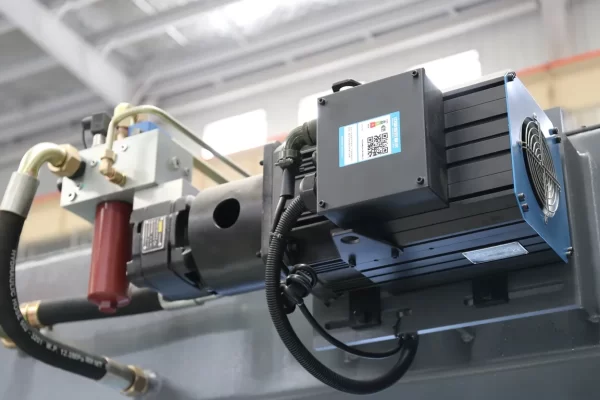

ESTUN & INNOVANCE Servo Motor

ESTUN & INNOVANCE servo motors deliver precise motion control, fast response, and high efficiency, enhancing press brake accuracy and overall performance.

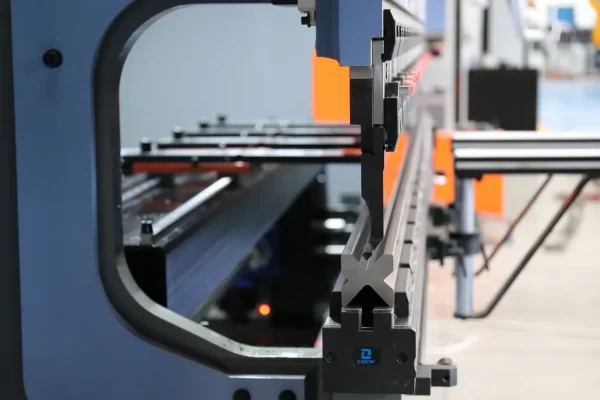

European Type 4V Tooling

The European Type Sectioned 4V Die & Punch offers versatile bending, quick setup, and high precision for enhanced press brake performance.

Optional Components

DSP Laser Protection

wila® tool holders

Light Protection

Crowning System

Tooling Cabinet

CNC Controlled Sheet Followers

Customized Look, Professional Build

Color matching recommendations

Calculate Your Bending Force

Use our bending force calculator to get precise press brake pressure results for any material and tooling setup.

Carbon Steel

Stainless Steel

Aluminum

Ensuring precision and durability across all metal forming applications.

See It In Action

Watch the DURMAPRESS All-Electric Press Brake demonstrate its precision and efficiency

GUIDE 1

How to install the Cylinder Guard Of Press Brake

How to Use DSP Laser Safety System For Press Brake To Protect You

guide 2

How to install the Press Brake and make preliminary preparations

How to install the Press Brake and make preliminary preparations

Ready to Transform Your metal Process?

Get a personalized quote for your specific needs and discover how the bending machine can enhance your production efficiency and product quality.

- Free consultation with our experts

- Customized solution based on your requirements

- Competitive pricing with flexible financing options

- Comprehensive training and ongoing support