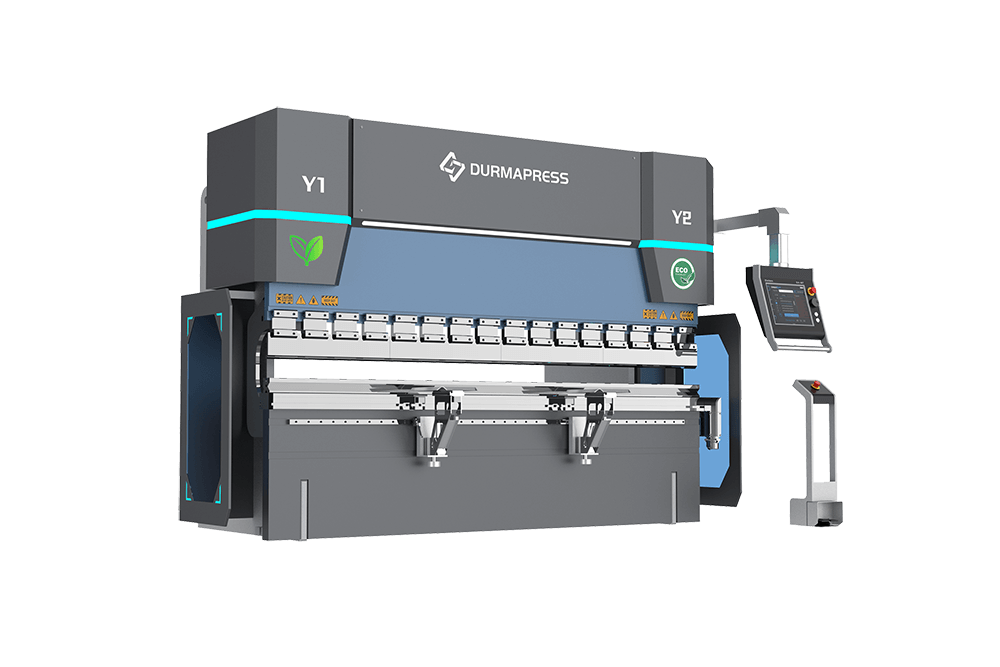

CNC servo Press Brake

The DP-ES Series Press Brake 3~4+1 Axis provides reliable precision and versatility for most bending applications. Increase your productivity with this durable and efficient solution.

Trusted by 5000+ manufacturers worldwide

Product Overview

Engineered for precision, efficiency, and reliability in modern manufacturing environments

Revolutionary Bending Technology

Advanced Technical Features

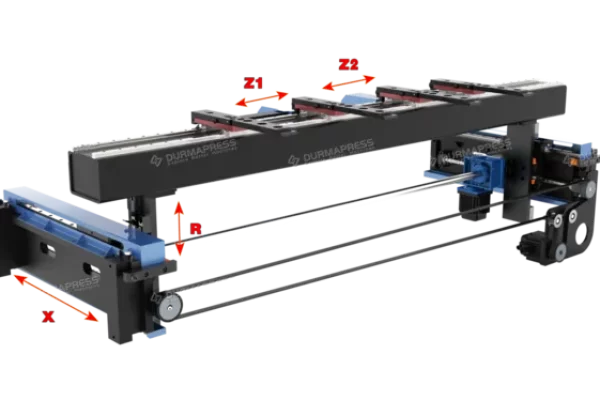

- Standard 4+1 Axis configuration (X, Y1, Y2, R + V) delivers precise motion control for a wide range of bending tasks.

- High dynamic performance significantly boosts machine productivity and overall processing efficiency.

- EU Directive–compliant design paired with a high-precision rear retaining system ensures safety, stability, and consistent accuracy.

- Servo motor with closed-loop speed control provides superior responsiveness, precision, and energy optimization.

- High-strength, thick-plate frame combined with low energy consumption minimizes operating costs while maximizing long-term reliability and cost-effectiveness.

Intuitive Control System

- Numerical touch screen programming

- 15" high resolution color TFT

- Crowning control

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- USB, peripheral interfacing

- Profile-T offline software

- DataM or Iris-Plus angle messurement management(options).

- EsaBend-3D software(options)

- Metalix, Radan, AutoPol 3d viewer(options)

Press Brakes CNC Control System

Customize The Controller For Your DP-ES Series

CybTouch 8 PS

The absolute excellence made CNC: powerful Windows PC integrated with Intel CPU and 18.5 “16: 9 mega-screen LCD HD Multitouch GlassOnly.

CybTouch 12PS

CybTouch 12PS Win is a compact 2D CNC system designed for mid-range CNC press brakes. Featuring an all-glass touchscreen.

Detailed Design & Components

Explore the precision engineering behind our press brake systems

Frame & Base Structure

Durmapress press brakes feature a robust mono-block frame made from high yield steel, ensuring enduring accuracy and reliability. Each frame is tempered and backed by a 15-year warranty.

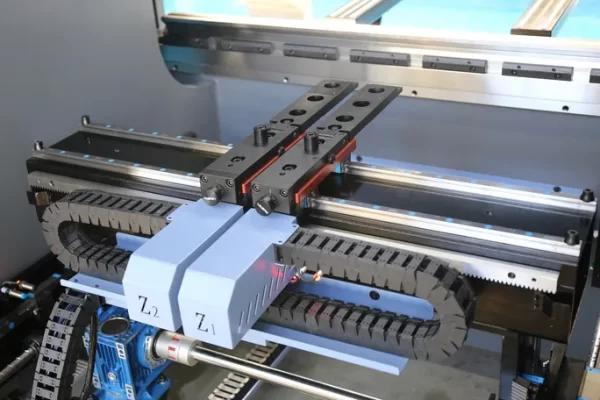

Backguage

We use Taiwan PMI ball screw and linear guide for X-axis precision, ensuring higher accuracy than rod-based systems. The back gauge, controlled by a servo motor with a timing belt & wheel mechanism, offers precise positioning.

CNC control System

The standard DELEM DA53T CNC control system is convenient for operators and is most suitable for our DP-ES Servo series press brakes..

Stop Finger

It ensures consistent processing position and size by precisely controlling the workpiece stop. The adjustable Stopper Finger position and height accommodate various workpiece sizes and shapes.

Front Support

The durable front supporter ensures long-lasting stability and precise positioning, reducing workpiece deformation and enhancing processing accuracy.

Fast Clamping

Durmapress's self-developed Side Fast Clamp can be used with various series to complete bending work including heavy machines. The tooling replacement is smooth and durable.

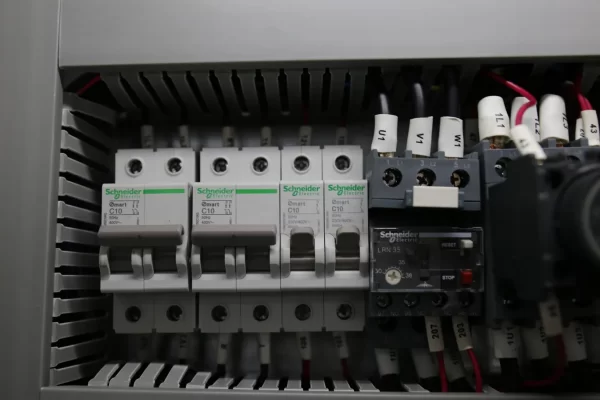

Schneider® Electrical Part

Schneider® electrical parts provide reliable power control, industrial-grade safety, and stable performance as standard components on our press brakes.

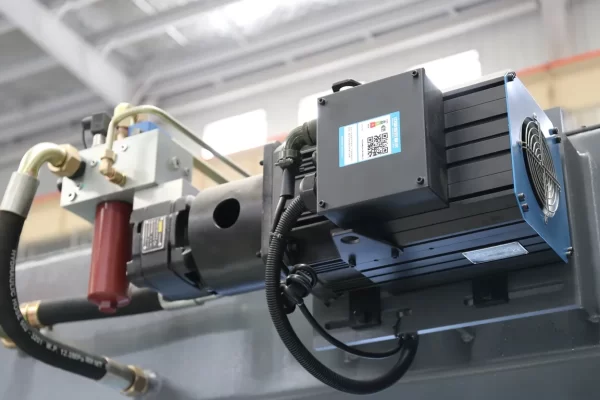

ESTUN & INNOVANCE Servo Motor

ESTUN & INNOVANCE servo motors deliver precise motion control, fast response, and high efficiency, enhancing press brake accuracy and overall performance.

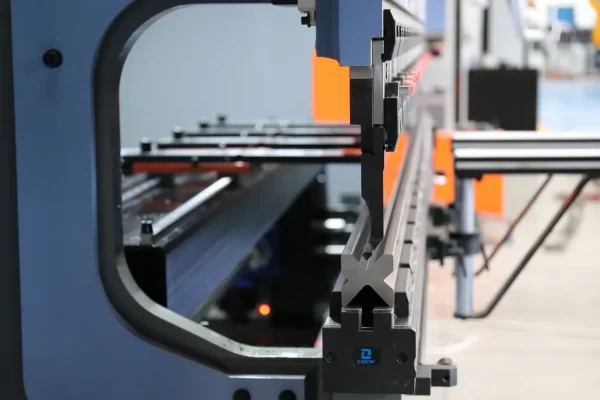

European Type 4V Tooling

The European Type Sectioned 4V Die & Punch offers versatile bending, quick setup, and high precision for enhanced press brake performance.

Optional Components

DSP Laser Protection

wila® tool holders

Light Protection

Tooling Cabinet

Laser Check

Combined Type Bending Follower

Core Configuration

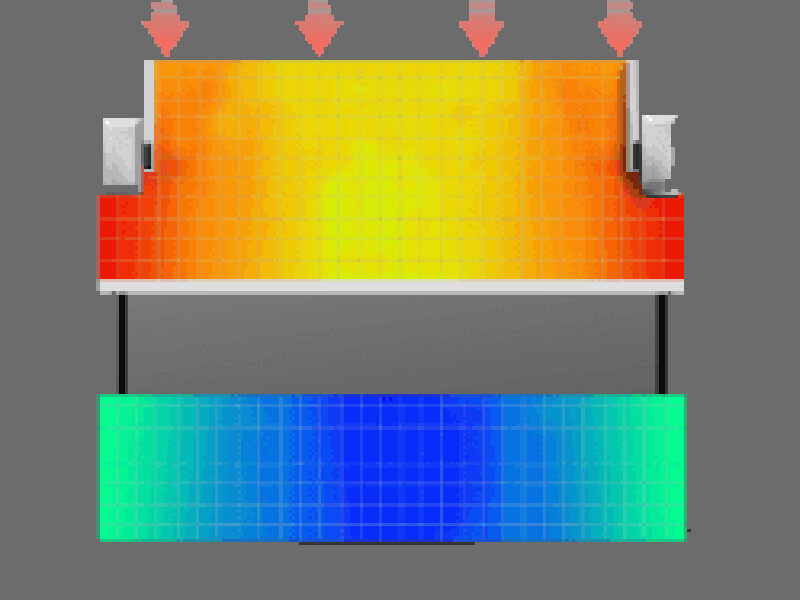

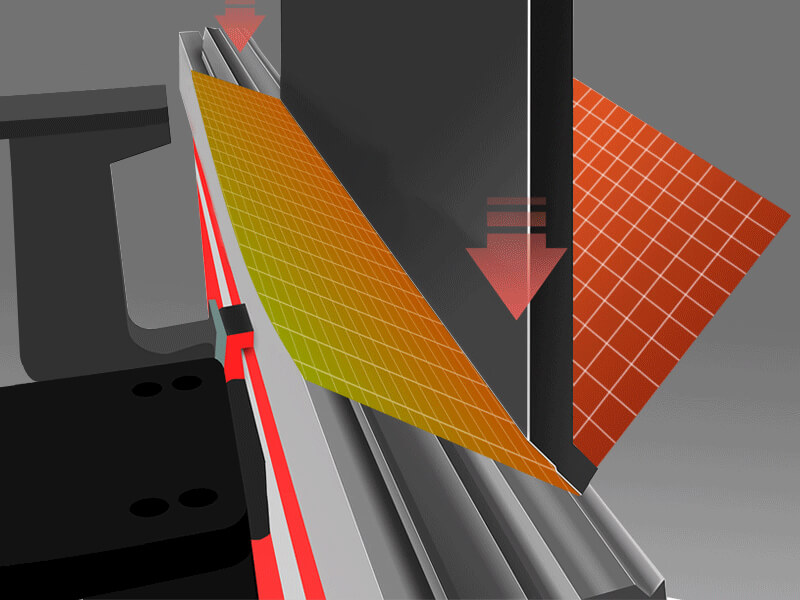

Design a stable body structure to improve mechanical stability, reduce vibration, and ensure accuracy and reliability during high-speed operation. Durmapress technology not only improves efficiency but also reduces material waste compared to traditional press brakes.

Our Press Brake use advanced technology to ensure that each stress point is evenly distributed, achieving precision and stability during the material bending process. No matter how complex the shape, our equipment ensures that every point receives the appropriate force, providing superior quality and reliability for your production.

Structural Features of Hydraulic Cylinders

- Cylinder Barrel: Made of high-quality alloy steel for strength and wear resistance.

- Piston: Forms a sealed cavity with the cylinder barrel, transmitting force through hydraulic pressure.

- Seals: Important for sealing and preventing leakage and contamination.

- Oil Port: Inlet and outlet for hydraulic oil entry, exit, and pressure adjustment.

Customized Look, Professional Build

Color matching recommendations

Calculate Your Bending Force

Use our bending force calculator to get precise press brake pressure results for any material and tooling setup.

Carbon Steel

Stainless Steel

Aluminum

Ensuring precision and durability across all metal forming applications.

See It In Action

Watch the DURMAPRESS All-Electric Press Brake demonstrate its precision and efficiency

Ready to Transform Your metal Process?

Get a personalized quote for your specific needs and discover how the bending machine can enhance your production efficiency and product quality.

- Free consultation with our experts

- Customized solution based on your requirements

- Competitive pricing with flexible financing options

- Comprehensive training and ongoing support