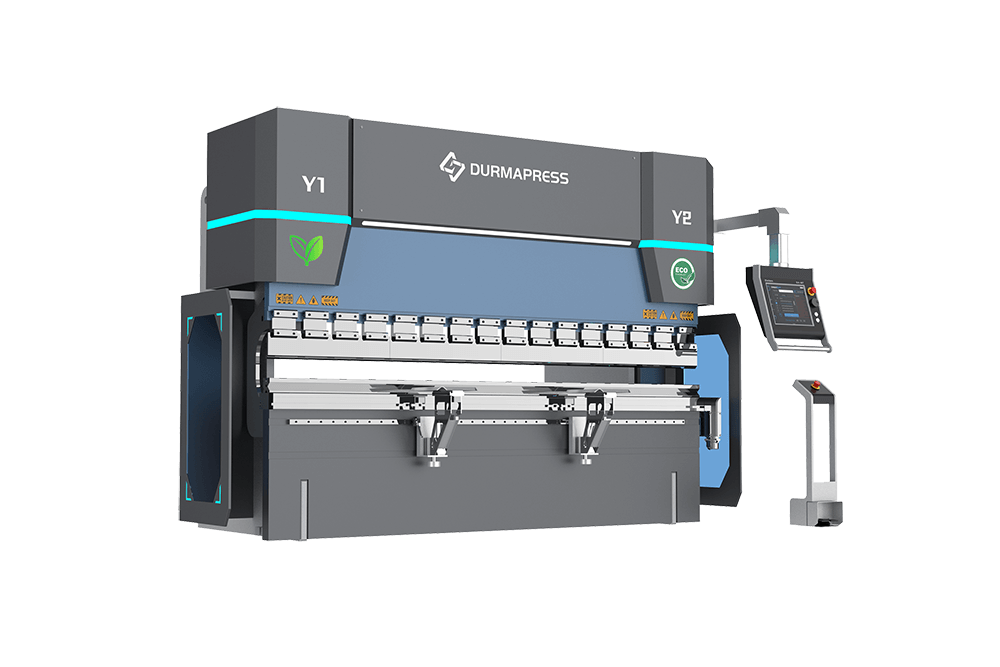

CNC servo Press Brake

The DP-ES Series Press Brake 3~4+1 Axis provides reliable precision and versatility for most bending applications. Increase your productivity with this durable and efficient solution.

Trusted by 5000+ manufacturers worldwide

Product Overview

Engineered for precision, efficiency, and reliability in modern manufacturing environments

Revolutionary Bending Technology

The DURMAPRESS CNC press brake machines are designed for precision, durability, and efficiency, providing the perfect solution for your metal fabrication needs.

Advanced Technical Features

- Standard 4+1 Axis configuration (X, Y1, Y2, R + V) delivers precise motion control for a wide range of bending tasks.

- High dynamic performance significantly boosts machine productivity and overall processing efficiency.

- EU Directive–compliant design paired with a high-precision rear retaining system ensures safety, stability, and consistent accuracy.

- Servo motor with closed-loop speed control provides superior responsiveness, precision, and energy optimization.

- High-strength, thick-plate frame combined with low energy consumption minimizes operating costs while maximizing long-term reliability and cost-effectiveness.

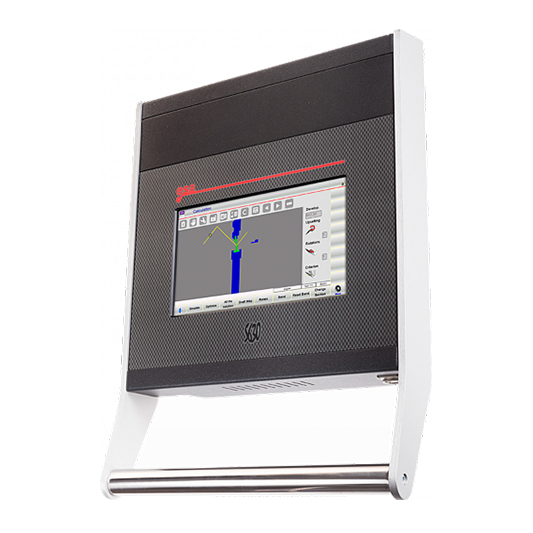

Intuitive Control System

Touch series provides modern compact and versatile solutions for a wide range of press brake applications without compromising machine functionality.

- Numerical touch-screen programming with a 15" high-resolution color TFT

- Support for up to 4 axes (Y1, Y2 + 2 auxiliary axes) and integrated crowning control

- Servo and frequency-inverter control, along with advanced Y-axis algorithms

- USB and peripheral interfacing

- Profile-T offline software streamlines programming and job preparation

Press Brakes CNC Control System

Customize The Controller For Your DP-ES PRO MAX Series

ESA S630

The most powerful in its class 10’ touch screen with powerful graphic All the performances of a high-level cnc in an economical and user-friendly controller.

CybTouch 8PS

CybTouch 8 PS is intended specifically for synchronized press-brakes.As part of the CybTouch range, it has an intuitive and vivid color touch screen and a high integration of functions.

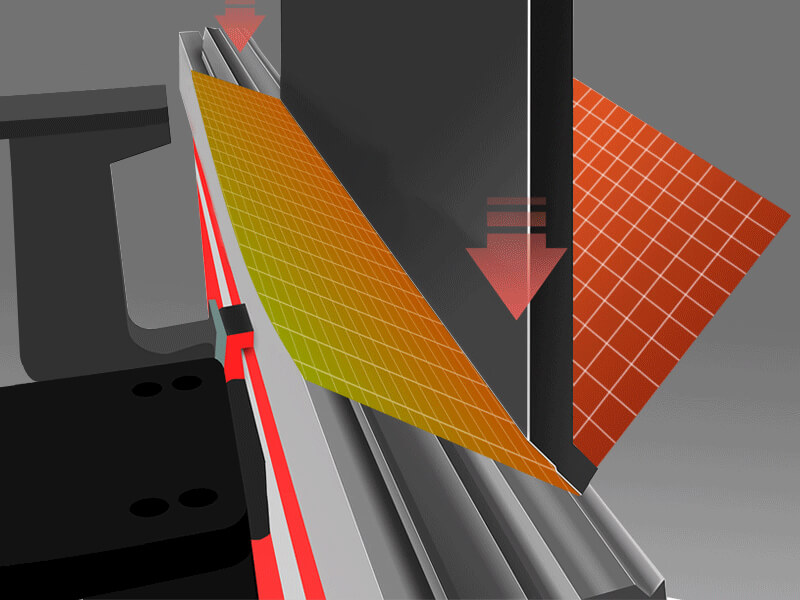

Detailed Design & Components

Explore the precision engineering behind our press brake systems

Frame & Base Structure

Durmapress press brakes feature a robust mono-block frame made from high yield steel, ensuring enduring accuracy and reliability. Each frame is tempered and backed by a 15-year warranty.

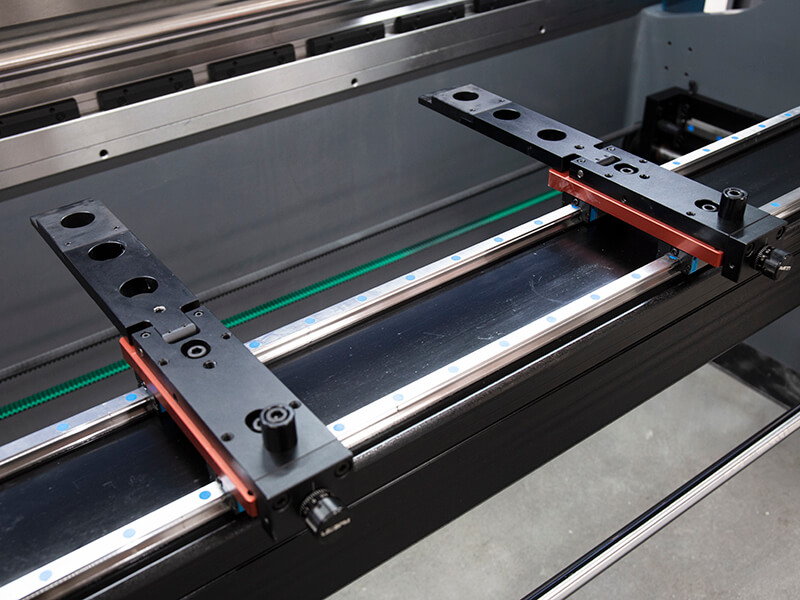

Backguage

We use Taiwan PMI ball screw and linear guide for X-axis precision, ensuring higher accuracy than rod-based systems. The back gauge, controlled by a servo motor with a timing belt & wheel mechanism, offers precise positioning.

CNC control System

The standard DELEM DA53T CNC control system is convenient for operators and is most suitable for our DP-ES Servo series press brakes..

Stopper Finger

It ensures consistent processing position and size by precisely controlling the workpiece stop. The adjustable Stopper Finger position and height accommodate various workpiece sizes and shapes.

Front Supporter

The durable front supporter ensures long-lasting stability and precise positioning, reducing workpiece deformation and enhancing processing accuracy.

Side Fast Clamp

Durmapress's self-developed Side Fast Clamp can be used with various series to complete bending work including heavy machines. The tooling replacement is smooth and durable.

other Components

Siemens® motor

wila® tool holders

Schneider® Electrical Part

Crowning System

European Type Sectioned 4V Die & Punch

CNC Controlled Sheet Followers

Get a quote now!

Get more details about DURMAPRESS®’s DP-ES PRO MAX SERIES CNC Servo Press Brake

Get Excited to move

Structural Features of Hydraulic Cylinders

Durable alloy steel hydraulic cylinders with:

- Two-way Cartridge Valve: Dg16-Dg160, 63-15000 L/min.

- Liquid Filling Valve: Dg40-Dg400, 300-35000 L/min.

- Plate Slide Valves: Relief, sequence, solenoid, throttle, and flow control valves.

- Cylinder Barrel: Made of high-quality alloy steel for strength and wear resistance.

- Piston: Forms a sealed cavity with the cylinder barrel, transmitting force through hydraulic pressure.

- Seals: Important for sealing and preventing leakage and contamination.

- Oil Port: Inlet and outlet for hydraulic oil entry, exit, and pressure adjustment.

See It In Action

Watch the DURMAPRESS All-Electric Press Brake demonstrate its precision and efficiency

Core Configuration

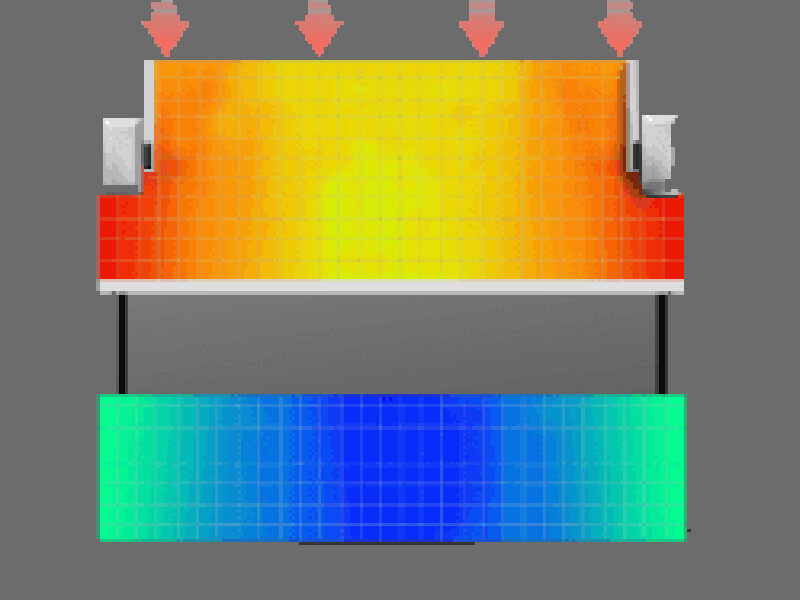

Design a stable body structure to improve mechanical stability, reduce vibration, and ensure accuracy and reliability during high-speed operation. Durmapress technology not only improves efficiency but also reduces material waste compared to traditional press brakes.

Our Press Brake use advanced technology to ensure that each stress point is evenly distributed, achieving precision and stability during the material bending process. No matter how complex the shape, our equipment ensures that every point receives the appropriate force, providing superior quality and reliability for your production.

GUIDE 1

How to install the Cylinder Guard Of Press Brake

How to Use DSP Laser Safety System For Press Brake To Protect You

guide 2

How to install the Press Brake and make preliminary preparations

How to install the Press Brake and make preliminary preparations

Ready to Transform Your metal Process?

Get a personalized quote for your specific needs and discover how the bending machine can enhance your production efficiency and product quality.

- Free consultation with our experts

- Customized solution based on your requirements

- Competitive pricing with flexible financing options

- Comprehensive training and ongoing support