HYDRAULIC NC Press Brake

General Features

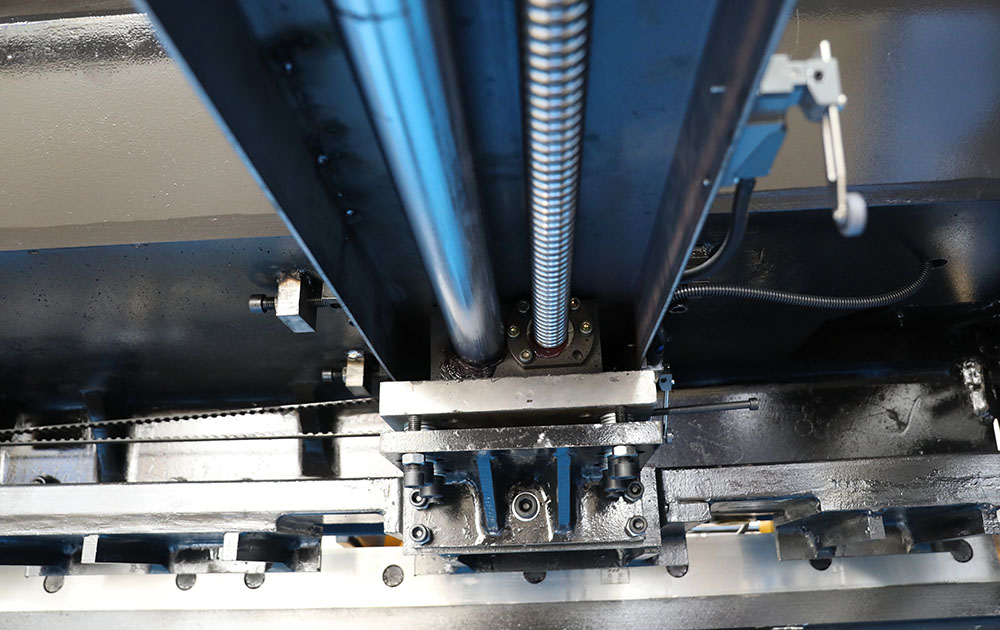

- Durmapress Guillotine Shearing machine adopt ball screw,linear guide and servo motor to drive the back gauge with high positioning accuracy

- Integrated steel welded structure,eliminate stress by vibration,with good rigidity

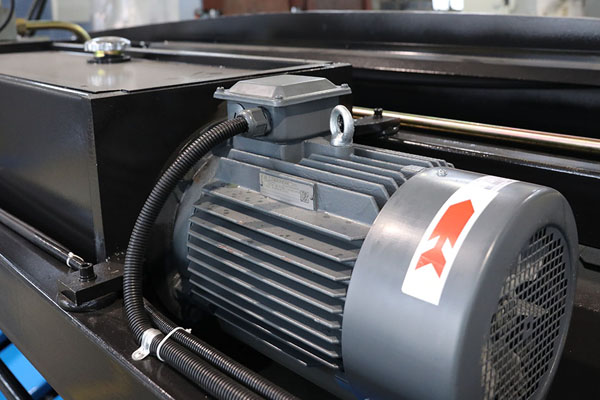

- Adopt the advanced hydraulic integrated valve block which is in compact structure and will reduce piping connections, and improves system reliability and maintainability

- Optional Estun E200PS, DELEM DAC310s and DELEM DAC360s, Cybelec CT8 CNC controller

- Serials connection of oil cylinder to prevent the cutting angle changing during the operation of the shearing machine

- Accumulator return smooth and rapid

- Manual/automatic adjustment of blade clearance (depend on the controller), accurate, rapid and convenient

- Adjustable shear angle to reduce sheet distortion Motorized back gauge and position display make it convenient and precise Rolling material support ball will reduce the scratch and frictions as well

E21S NC Controller From ESTUN

Controller Data

- High-definition LCD display with Chinese and English language options. Programming parameters can be displayed on one page, making programming faster and more convenient.

- Backgauge: Intelligent positioning, manual adjustment can also be performed as needed, and mechanical manual positioning device is eliminated.

- Shearing stroke: Built-in shearing time relay, easy operation and cost saving.

- Cutting angle: built-in cutting angle adjustment function, eliminating the angle indicator and buttons.

- Knife edge clearance: encoder feedback, timely display of knife edge clearance, easy and convenient operation.

- With one-key parameter backup and recovery function, parameters can be restored at any time as needed, reducing maintenance costs.

- All keys on the panel are micro switches, which have passed strict tests such as EMC, high and low temperature, and vibration to ensure product stability and service life.

Would you like the brochure ?

Guillotine Shearing Machine

After shearing, the shearing machine should be able to ensure the straightness and parallelism of the shearing surface of the sheared sheet, and minimize the distortion of the sheet to obtain high-quality workpieces. The upper blade of the shearing machine is fixed on the knife holder, and the lower blade is fixed on the workbench. A material holding ball is installed on the workbench to prevent the sheet from being scratched when sliding on it. The back gauge is used for positioning the plate, and the position is adjusted by the motor. The pressing cylinder is used to compress the sheet material to prevent the sheet material from moving during shearing. The guardrail is a safety device to prevent industrial accidents.

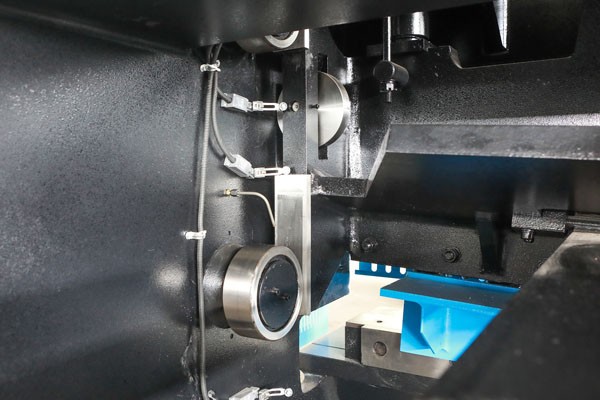

Blade clearence adjustment

Adjust the cutting blades gap by motor according the cutting thickness of the metal sheet can get better cutting performance

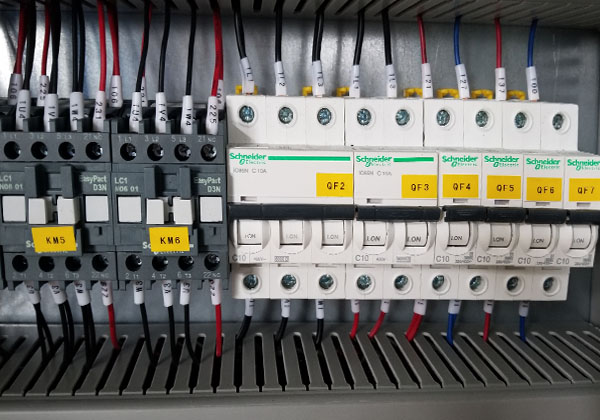

French schneider electrics

French schneider electrics to ensure machine stability , and Estun servo drive to control the accuracy of X Back Guage Open Door Power Off

OTHER COMPONENTS

Write us today

Write us today and our experts are ready to help. You can contact us by the contact form below or write us email or make a phone call!