Hydraulic Heavy Duty Guillotine Shearing Machine

Next-generation QC11Y CNC shearing for flawless sheet cutting.

Trusted by 5000+ manufacturers worldwide

Product Overview

Engineered for precision, efficiency, and reliability in modern manufacturing environments

Revolutionary Cutting Technology

The DURMAPRESS cutting-edge shearing machines are designed for precision, durability, and efficiency, providing the perfect solution for your metal fabrication needs.

Advanced Technical Features

- Equipped with hydraulic synchronization control and advanced programmable logic controller

- The hydraulic system allows for quick and automatic switching between fast and slow cutting modes.

- Exceptional precision and user-friendly operation.

- Built to withstand heavy-duty usage for long-lasting reliability

- Ideal for cutting various sheet metal types with ease.

Intuitive Control System

Equipped with the industry-leading ESTUN E21S control system featuring:

- Cut-angle&Cut-gap can be controlled

- Intelligent positioning control

- Sheet thickness measurement

- Unilateral and bidirectional positioning which eliminates spindle clearance effectively

Ideal Applications

- Stainless Steel Kitchenware

- Precision Sheet Metal

- Automotive Components

- Electrical Enclosures

- Medical Equipment

- Telecommunication Racks

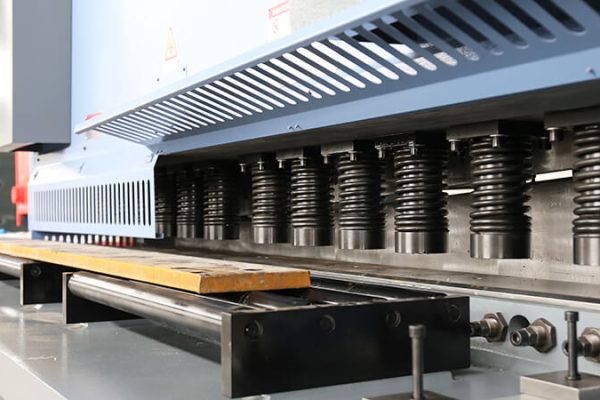

Detailed Design & Components

Explore the precision engineering behind our laser marking systems

Machine Frame

Robust steel frame construction providing stability and vibration dampening for precision cutting operations.

Backguage

The backgauge system features automatic positioning, reducing operator labor intensity and enhancing work efficiency and comfort.

Controller

ESTUN E21S controller enhances the efficiency, precision, and user experience of hydraulic shearing machines, making it a valuable component in metal fabrication processes.

Auto Blade Clearence Adjustment

Use sensors, controllers, and actuators to continuously monitor and adjust the gap between blades to an optimal range (typically 5–10% of material thickness)

Press Cylinder

The press cylinder applies pressure to hold the material firmly in place during the cutting process. This prevents the material from moving or shifting, ensuring accurate and clean cuts.

Electrical System

The electrical system includes all the electronic components that control and monitor the shearing machine's operations.

Motor

Siemens motors in shearing machines offer significant advantages, including extended service life, reduced operational noise, and enhanced cutting precision.

Ball Integrated Front Tables

These tables are equipped with balls or rollers that facilitate easy and smooth movement of the material. They help in positioning the material accurately under the blade, reducing manual effort and improving cutting precision.

Hydraulic Valve

Hydraulic valves control the flow and pressure of hydraulic fluid within the system. They regulate the movement of the blades and other hydraulic components, ensuring precise and controlled cutting actions.

Manual Knife Clearence

The knife adjust mechanism allows for precise adjustment of the blade clearance. Proper blade clearance ensures clean and accurate cuts, reduces wear on the blades, and prevents material deformation.

Ball Screw

Ball screws are used for converting rotational motion into linear motion with high precision and efficiency. In a shearing machine, they are typically employed in the back gauge system to ensure accurate positioning and movement of the material being cut.

Optional Equipment

Pneumatic Sheet Support System

Auto Front Feeder System

Angle Positioning

P40 CNC Controller

Light Curtain

Laser Cutting Line

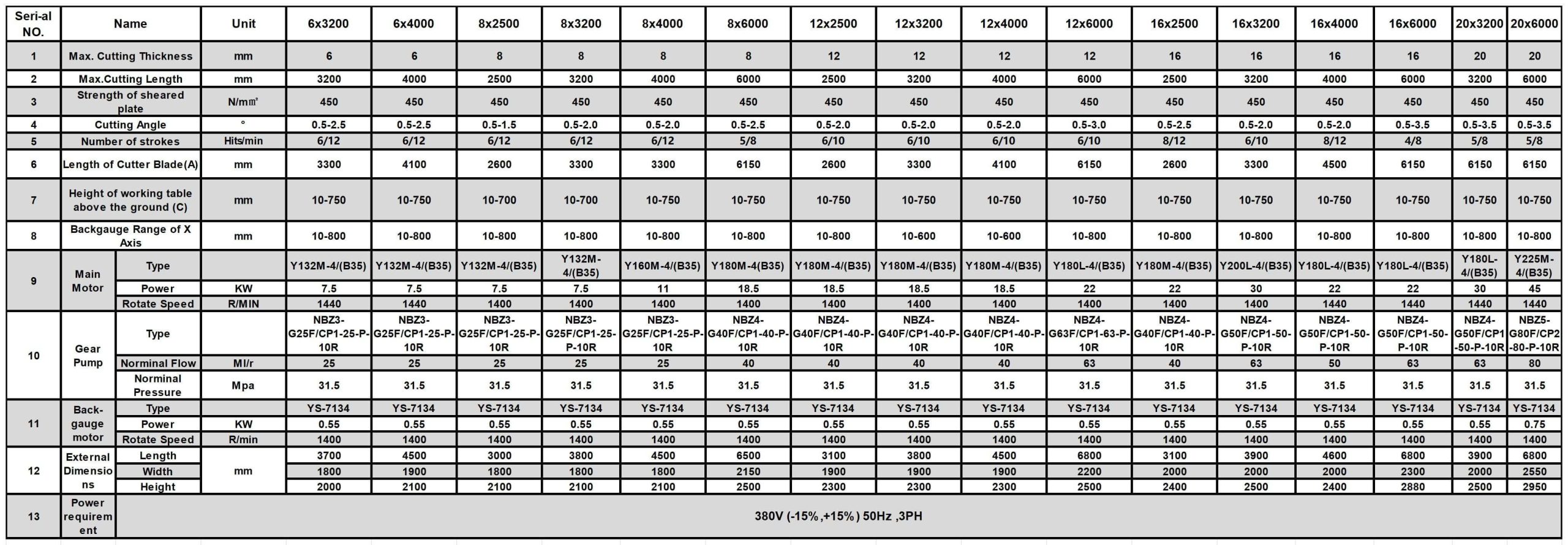

Technical Specifications

Engineered to deliver exceptional performance across a range of manufacturing requirements

For complete technical specifications and custom configuration options

Why Choose us

Verified welded steel structures

Cutting capacity

Global Component Brands

Watch the Video

Manufacturer of cutting-edge metal processing equipment

durmapress factory

Ready to Transform Your metal Process?

Get a personalized quote for your specific needs and discover how the shearing machine can enhance your production efficiency and product quality.

- Free consultation with our experts

- Customized solution based on your requirements

- Competitive pricing with flexible financing options

- Comprehensive training and ongoing support

- 5-Year Warranty