HYDRAULIC IRONWORKER MACHINE

General Features

The Ironworker machine adopts hydraulic transmission. It is the latest product of the domestic multi-functional combined punching and shearing machine. It can cut, punch, die cut flat steel, square steel, round steel, angle steel, channel steel, and I-beam. Equipped with shear stop device. It is a machine tool that integrates multiple functions such as metal shearing, punching, plate shearing, bending, etc. It has the advantages of simple operation, low energy consumption, and low maintenance cost.

The structure includes:

- Punching station

- Section cutting station

- Angle Cutting station

- Shearing station

- Notching station

COMPONENTS

Standard Components

- A set of punch and die(round hole)

- A set of angle steel blade

- A set of square and round bar blade

- A set of shearing plate blade

- A set of notching blade

- 2 independent hydraulic piston rods and foot-pedal allows two people operating at the same time

- More efficient stroke-control functions of piston rod

- Central lubricating system

- Motor-driven rear stopper

- Lighting devices for work

- 5 independent work-positions

Optional

- Various toolings for different purposes

- Square, oval, louver punch and die

- Channel shear and I-beam shear

- Conveyor table

- Longer worktable

- Worktable with linear guide

- Φ20, 32, 60mm U type circle

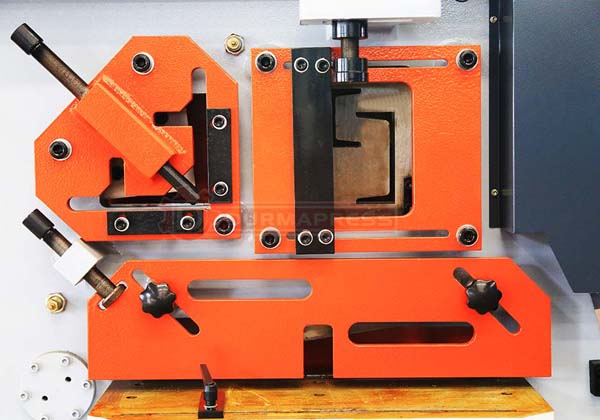

Angle station

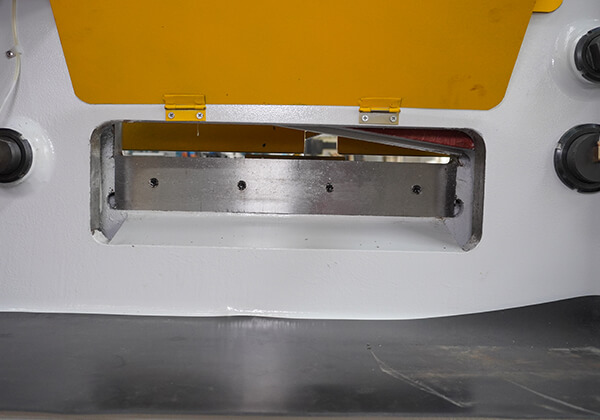

Shearing station

Punching station

Ironworker Machine Video

Operation

Our 7 different models of 5-station ironworkers range from 60 tons to 135 tons in pressure capacity. Each 5-station hydraulic ironworker machine offers: Stations for punching, notching, flat bar shearing, angle shearing, and bar shearing. Pure vertical hydraulic motion at each station, which extends tooling life and reduces stress on the machine (unlike the pivot mechanisms on some competing machines). Oversized work tables with scales and adjustable guides for repeatable results. Heavy-duty stop rod system for the shearing station that minimizes waste and increases precision. 7 punches and dies to increase the machine’s variety of applications. Rigid steel construction to eliminate flexing.

OTHER COMPONENTS

Optional Toolings

TECHNICAL DATA

| Model | Unit | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 |

|---|---|---|---|---|---|---|

| Pressure | T | 60 | 90 | 120 | 160 | 200 |

| Max. Cutting thickness of steel plates | mm | 16 | 20 | 25 | 30 | 40 |

| Plate strength | N/mm² | 450 | 450 | 450 | 450 | 450 |

| Angle of shear | ° | 7 | 8 | 8 | 8 | 8 |

| Shearing size of one stroke | mm | 16X250 8x400 | 20X330 10x480 | 25X330 16x600 | 30X335 20x600 | 40X335 30x600 |

| Ram Stroke | mm | 80 | 80 | 80 | 80 | 100 |

| Number of strokes | Times/min | 11/20 | 12/20 | 8/18 | 6/16 | 6/16 |

| Throat depth | mm | 300 | 355 | 400 | 600 | 530 |

| Punching thickness | mm | 16 | 20 | 25 | 28 | 35 |

| Max.punching diameter | mm | 25 | 30 | 32 | 38 | 45 |

| Main motor power | KW | 5.5 | 7.5 | 11 | 15 | 18.5 |

| Overall dimension (LxWxH) | mm | 1740X810X1830 | 1950X900X1950 | 2355X960X2090 | 2800X1050X2450 | 2900X1150X2550 |