Medical devices are far different from general industrial products, which directly or indirectly affect human body and affect human life.

This determines that the state controls the manufacturing process of this industry more strictly than any other type of manufacturing product.

In order to meet strict standards, the accuracy of the product can not be careless. At this time, laser processing will play a key role.

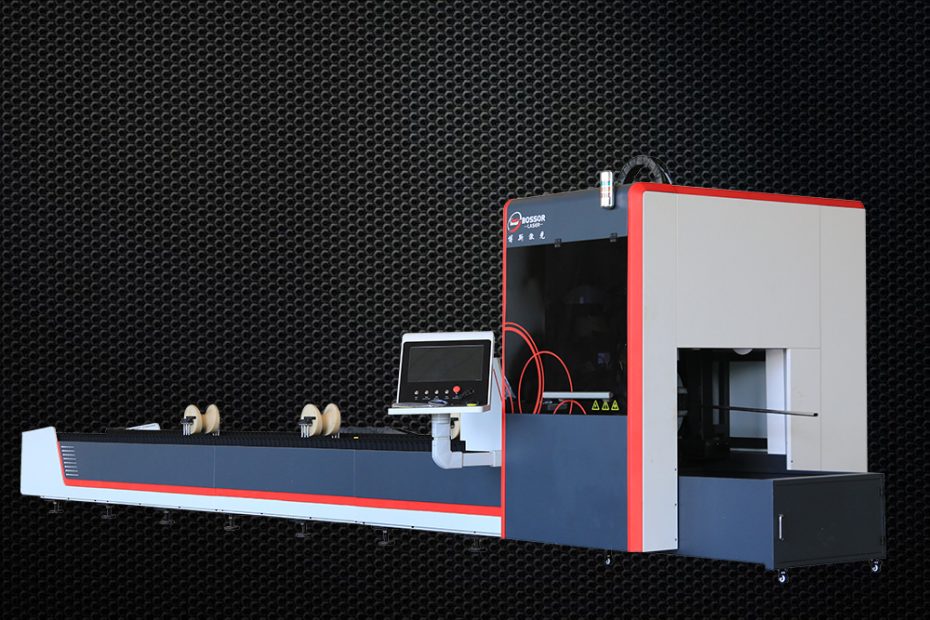

2000w Laser cutting can realize blanking cutting in metal parts of medical equipment,

can also use ultra-precision laser processing to make micro medical equipment, or directly use laser to achieve minimally invasive surgery.

Applications of laser cutting in medical device manufacturing include the manufacture of stents, heart valves 2000W laser cutting ,

medical tools and device components. The advantages of laser cutting mainly include: the ability to control part deformation to minimize,

the ability to cut accurately, no tool wear, faster prototyping, and the ability to cut most metals and materials.

Laser technology plays an important role in the medical field with its characteristics of high precision, high efficiency and non-contact.