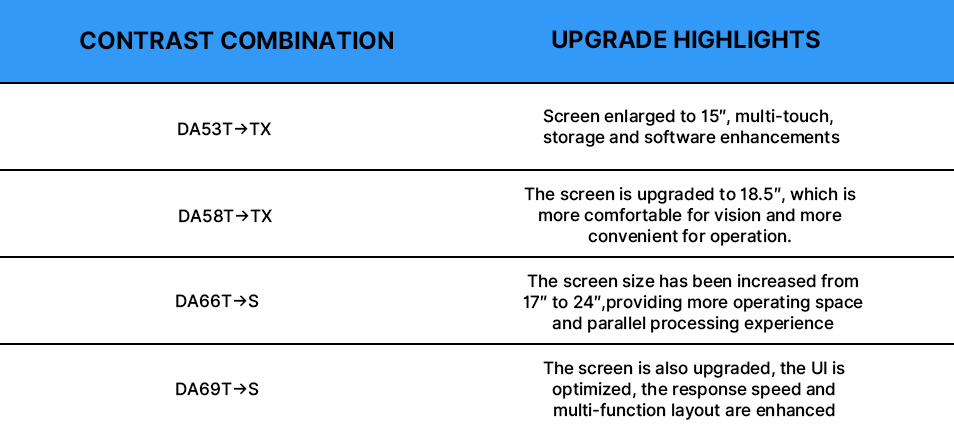

As sheet metal processing accelerates its transformation towards intelligence and flexibility, DELEM, the world's leading bending control system brand, has completed the full range of technology iterations in 2025. This article will analyze the upgrade differences of the six core models of DA53T/Tx, DA58T/Tx, DA66S/T, and DA69T/S to help you accurately match your production needs.

.jpg)

Why focus on DELEM 2025 upgrade?

1.Improve operational efficiency and productivity

Larger touch screen: The Tx and S series control systems have upgraded the screen to 15″, 18.5″, 24″ and other sizes. The wider graphical interface makes programming, bending simulation and settings more intuitive, reducing operating errors and process adjustment time.

Powerful hardware storage: For example, the DA-69S has 4GB storage and 3GB product/tool library, which speeds up program loading, model loading and storage access, and significantly shortens the time for loading and unloading and switching workpieces.

Efficient algorithm and realistic simulation: The new generation controller adopts optimized control algorithm to achieve smarter bending rhythm, adaptive setting and collision detection, improve the accuracy of first commissioning, and simplify complex bending processes.

2.Stable precision and high quality assurance

Automatic detection and correction function: supports 2D/3D collision detection, angle sensor feedback and tilt compensation, etc., which helps to maintain bending consistency and reduce defective rate.

Multi-axis collaborative control: supports up to 8+1 axis collaborative bending (such as DA‑69S), which can precisely control complex parts and make high-precision production controllable and reliable.

Real-time monitoring and visual feedback: 3D simulation and real-time visual effects can foresee problems in advance, effectively reducing actual trial folding and material waste.

3.Smarter integration for future compatibility

Modular scalable architecture: Using DELEM Modusys and Windows application architecture, it can be seamlessly integrated with workshop MES, robot system, ERP, etc.

Standard interface unification: New functions such as large USB storage, network transmission, high-speed field bus, and DXF import are added, which are suitable for digital workshops and IT docking, and realize the "online-offline-feedback" digital closed loop.

Offline programming and collaborative production: Supports Profile‑TL/‑S2D/‑T3D offline programming software, which can be prepared in advance in the synchronization software to reduce on-site preparation time, and supports cloud data management.

Cost-effective choice: DA53T and DA53Tx

1.Screen and touch experience

The DA‑53T is equipped with a 10.1″ high-definition color TFT and supports hot‑key touch operation. The DA‑53Tx is upgraded to a 15″ high-resolution TFT + industrial-grade multi-touch, providing a larger display and a smoother interactive experience.

2.Storage and Software

The DA‑53Tx offers increased storage (e.g. 1 GB storage, 256MB tool/product library) and comes standard with enhanced offline software Profile‑53TL.

3.User efficiency and data transfer

DA‑53Tx continues the USB interface and TandemLink, synchronization functions, but further optimizes the navigation layout and program‑production switching efficiency.

The DELEM DA53T control system offers a powerful and user-friendly interface designed for efficient press brake operation. It features a "hot-key" touch navigation system and a 10.1" high-resolution color TFT display for clear, intuitive control. Supporting up to 4 axes (Y1, Y2, and 2 auxiliary axes), it enables precise and flexible bending operations.

The DA53T includes advanced capabilities such as crowning control, a comprehensive tool/material/product library, and both servo and frequency inverter control. It is equipped with sophisticated Y-axis control algorithms for both closed-loop and open-loop systems, ensuring consistent performance and accuracy.

Additional options include TandemLink for multi-machine synchronization, USB memory stick support for easy data transfer, and Profile-T offline programming software for streamlined workflow and setup preparation.

The DA53TX control system features a 15-inch high-resolution color touchscreen for intuitive numerical programming. It supports crowning control and utilizes both servo and frequency inverter technologies for precise and efficient performance. With advanced Y-axis control algorithms, it accommodates both closed-loop and open-loop valve systems. The controller also offers USB and peripheral interfacing for easy data transfer and is compatible with Profile-T offline software, enabling flexible and efficient offline programming.

Precision manufacturing tools: DA58T and DA58Tx

1.Display and convenience

The DA‑58T features a 15″ industrial touchscreen that supports 2D graphics programming, automatic bending sequences, and collision detection.

DA‑58Tx has been upgraded to a 18.5″ large screen with enhanced graphics capabilities, making operation more intuitive and labor-saving, and providing a better interactive experience.

2.Performance and Compatibility

58Tx and 58T both support Crowning, servo + variable frequency control, Y-axis closed-loop/open-loop algorithm, USB interface, and Profile‑T, but 58Tx provides better visual experience and ease of use.

DA58T boasts the following features: It supports 2D graphical touch screen programming, is equipped with a 15 - inch high - resolution color TFT. It enables bend sequence calculation and crowning control, and implements servo and frequency inverter control. There are advanced Y - axis control algorithms for both closed - loop and open - loop valves. It also offers USB and peripheral interfacing, along with Profile - T offline software.

DA58Tx comes with the following features: It supports 2D graphical touch screen programming, is equipped with an 18.5 - inch high - resolution color TFT. It can perform bend sequence calculation and crowning control, and realizes servo and frequency inverter control. There are advanced Y - axis control algorithms applicable to both closed - loop and open - loop valves. It also provides USB and peripheral interfacing capabilities, along with Profile - T offline software.

The core of automated production lines: DA66S and DA66T

1.Screen size and interface

DA‑66T features a 17″ high-resolution touchscreen; DA‑66S available in a larger 24″ version.Both support 2D programming, 3D graphics simulation, Modusys Windows application, angle detection function, etc.

2.Multitasking and operation layout

The DA‑66S’s larger interface allows for easy multi-window/multi-tasking operation, with a wider layout for tool setup and programming. It is still compatible with Profile‑TL/S2D.

DA66T has the following features: It offers a 2D graphical touch screen programming mode, is equipped with a 17 - inch high - resolution colour TFT, and comes with a full Windows application suite. It has Delem Modusys compatibility, enabling module scalability and adaptivity. It supports USB and peripheral interfacing, provides user - specific application support within the control’s multitasking environment, and includes a sensor bending & correction interface along with Profile - TL offline software.

DA66S features include: 2D graphical touch screen programming mode; 3D machine representation available in both simulation and production; a 24 - inch high - resolution color TFT; Delem Modusys compatibility with module scalability and adaptivity; USB and peripheral interfacing; support for user - specific applications within the control’s multitasking environment; a sensor bending & correction interface; and Profile - S2D offline software.

Complex surface experts: DA69T and DA69S

1.Layout and target users

DA‑69T with 17″ screen is a top-level 2D+3D control solution with multi-tool station and collision detection.DA‑69S offers a larger 24″ touchscreen and a richer interface, optimizing ergonomics and multi-tasking layout.

2.Functional enhancements

DA‑69S has enhanced algorithms to further improve machine efficiency and response speed, while supporting the same 2D/3D programming, collision detection, tool station management, etc.

DA69T features include: It supports 3D and 2D graphical touch screen programming modes. It enables 3D visualisation during both simulation and production processes. It is equipped with a 17 - inch high - resolution colour TFT. It comes with a full Windows application suite. It offers Delem Modusys compatibility, allowing for module scalability and adaptivity. It provides USB and peripheral interfacing capabilities. It supports user - specific application development within the control’s multitasking environment. It has a sensor bending & correction interface. Additionally, it includes Profile - T3D offline software.

DA69S has the following features: It supports 3D and 2D graphical touch screen programming modes. It offers 3D visualization, including 3D machine representation, in both simulation and production. It is equipped with a 24 - inch high - resolution color TFT. It is compatible with Delem Modusys, featuring module scalability and adaptivity. It provides USB and peripheral interfacing. It supports user - specific application development within the control’s multitasking environment. It has a sensor bending & correction interface. Additionally, it comes with Profile - S3D offline software.

Summary and recommendations

After the upgrade, the Tx/S series has significantly enhanced the strength of "visual operation, storage capacity, and graphic simulation efficiency", and significantly improved programming speed, accuracy, and user experience. It is suitable for more efficient, more sophisticated, and highly complex production scenarios.

How to choose

Limited budget and simple requirements: Choose DA‑53T/Tx for basic high-precision bending and multi-axis control.

Medium complexity, high automation requirements: Choose DA‑58T/Tx with automatic bending sequence and screen upgrade to improve efficiency.

High-precision complex parts: DA‑66T/S is recommended, which supports 3D model settings and high customization functions.

For the most advanced and flexible production: choose DA‑69T/S, which fully supports 3D programming, large-screen display, and multi-tool station management.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.