Why is the 3200 press brake one of the most popular models?

The 3200 Press Brake is one of the most popular models, mainly because of its excellent machining capabilities and wide range of applications. This press brake is able to cope with a wide range of complex metal working tasks, from large parts to delicate components. Its large table size makes it suitable for handling even larger workpieces, increasing productivity. In addition, the 3200 press brake is equipped with a wide range of features and flexible configurations, and can be equipped with a wide range of tools and dies for a variety of machining methods, such as bending, drawing, punching, etc., to meet the needs of different industries. In many fields such as aerospace, construction, electronics, etc., 3200 press brake plays an important role and provides strong support for the development of metal processing industry.

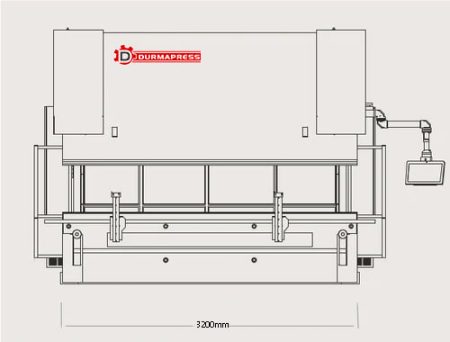

Introducing the 3200 press brake and its importance in the metalworking industry

The 3200 press brake is a sheet metal bending machine with a maximum bending length of 3200 and is suitable for medium-sized metalworking tasks and can handle many common workpiece sizes. It can cope with complex metalworking tasks, whether for large parts or fine components. Its powerful machining capabilities make it useful in areas as diverse as bridges, ships, engines, jewelry, watches, etc. Precise control systems and high-precision machining processes are also essential to ensure dimensional accuracy and machining quality for high-quality metal machining.

At the same time, the 3200 press brake offers a wide range of functions and flexible configurations that can be adapted and optimized for different processing requirements. For example, according to different production bending needs, it is highly flexible and can be equipped with a variety of tools and molds to achieve a variety of processing methods, such as bending, stretching, punching and so on. In addition, some models are equipped with automatic feeding and loading/unloading functions, which further improve production efficiency.

The video details the construction of a 3200mm press brake.

Features of the 3200 Press Brake

High-precision stamping capability

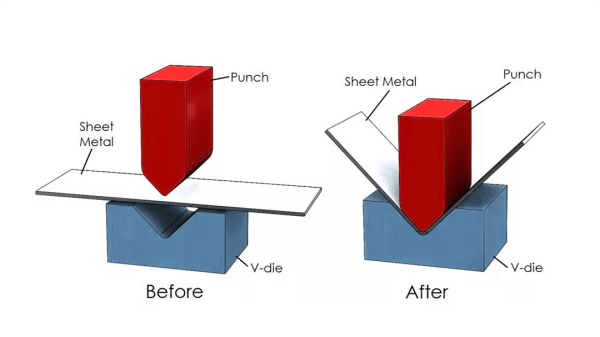

In modern manufacturing industry, stamping process is a crucial technology, and high-precision stamping capability is an important index to measure the performance of stamping equipment. 3200 press brake, as an excellent stamping equipment, plays a key role in manufacturing industry with its high-precision stamping capability. High-precision stamping capability means that the machine can achieve millimeter-accurate stamping results, which is essential for producing high-quality products.

The 3200 press brake offers excellent machining accuracy for stamping a wide range of complex parts. Whether it's a large workpiece or a small part, its high-precision stamping capability ensures that every detail of the process is accurate. This capability allows operators to confidently produce parts and products with dimensional accuracy and consistent quality.

Large Format Stamping Capability

Large format stamping technology plays a vital role in modern manufacturing, especially in large industries such as automotive and aerospace. These industries have an urgent need for large-format stamping capabilities, which are required to produce large parts that offer significant advantages in terms of material savings and lower production costs. 3200 press brake is a powerful large-format stamping machine that plays an important role in this regard.

This press technology also has a wide range of applications, not only in the automotive and aerospace sectors, but also in various industries such as construction, home appliances and electronics. In order to meet the needs of these sectors, large-size stamping presses need to be highly technical and have complex structural designs. 3200 press brake is one such machine, which has been precisely designed and manufactured to provide a powerful stamping capability that can easily cope with a wide range of large-size parts stamping tasks.

Efficient and stable press performance

Efficient and stable press performance means that the machine maintains accuracy and stability at high speeds, resulting in high-quality press results. In addition, efficient and stable stamping performance also requires good troubleshooting and automatic protection functions to ensure that the equipment can be stopped in time when it encounters a problem, so as to avoid causing greater losses.

Humanized operation interface

With the development of technology, the operation interface of stamping equipment is becoming more and more humanized. The humanized operation interface means that the users of the equipment can familiarize themselves with the operation process in a short period of time, thus lowering the threshold of use. The humanized operation interface also includes rich information display and data analysis functions, so that the operator can understand the real-time operation status of the equipment and adjust the production strategy promptly. In addition, the humanized operator interface should also have good protective measures to ensure the safety of the operator.

To sum up, high precision, large size, high efficiency and stability, and humanized operation interface are the important features of modern stamping equipment. Stamping equipment with these characteristics can not only meet the enterprise's demand for high-quality and high-efficiency production but also improve the competitiveness of enterprises and help China's manufacturing industry to transform and upgrade. When choosing press equipment, enterprises should fully consider these characteristics to ensure that the purchase of high-quality press equipment meets their needs.

Advantages of 3200 press brake

Improve production efficiency

With excellent processing capability and high precision, 3200 press brake can quickly and accurately complete a variety of complex stamping tasks. Its high-speed stamping capability and quick response time to movements greatly increase productivity. Operators can accomplish more processing tasks in less time, speeding up production cycles and reducing manufacturing costs.

Broadening the range of applications

The machine's versatility and flexible configurations allow it to be adapted to a variety of different machining needs. Whether it's a large part or a tiny component, the 3200 press brake can handle it. At the same time, it can also be equipped with a variety of tools and molds to achieve different processing methods, such as bending, stretching, punching, etc., thus broadening its scope of application in various industries.

Reducing labor intensity of workers

The 3200 press brake's automated functions and user-friendly operation interface greatly reduce the labor intensity of operators. The automated loading and unloading function and intelligent CNC system make the operation easier and more convenient. The operator only needs to simply set the parameters, and the equipment can automatically complete most of the work, which reduces the physical labor of workers and improves the operation efficiency.

Reliability and Durability

This equipment is designed with precision and selected with high quality materials to provide excellent reliability and durability. Its stable operation and long service life make the production process more stable and reliable. Operators can produce with confidence, reducing equipment failures and downtime, and improving the stability and sustainability of the production line.

Application Scenarios for 3200 Press Brake

Automotive Parts Processing

In the stamping processing of automotive parts, 3200 press brake plays a vital role as an important stamping equipment. It can process various metal sheets into required shapes and sizes through strong pressure and precise mold control, and is widely used in the production of automotive cover parts, structural parts and other components. 3200 press brake has high press force and rigidity, which can ensure precise control of metal sheets during processing. Meanwhile, it is also equipped with advanced mold and fixture system, which can be quickly changed according to the processing needs of different parts, improving production efficiency and flexibility. Secondly, the 3200 press brake adopts advanced CNC technology, which can realize high-precision press processing. By accurately controlling the closing height and pressure of the mold, it can ensure that the size and shape of the processed parts meet the design requirements, and reduce the correction and adjustment work in the later stage. 3200 press brake is safe and reliable, and in the process of machining, it can automatically detect abnormalities of molds and fixtures, and take timely protective measures to prevent equipment damage and accidents of personnel injury or death. Meanwhile, it is also equipped with perfect safety protection devices, such as photoelectric protection device, emergency stop button, etc., which further guarantees the safety of operators.

Processing of body covering parts and structural parts

Processing of body covering parts and structural parts is one of the crucial links in the automobile manufacturing industry. The 3200 press brake plays a key role in this process. This high-performance machine is capable of handling sheet metal up to and exceeding 3,200 mm in thickness, providing a precise and reliable machining solution for the manufacture of bodywork components.

With the Model 3200 press brake, operators can easily bend and form sheet metal to achieve a wide range of complex shapes. For body cladding parts, this means being able to accurately produce doors, hoods, roofs and other parts that meet design requirements. As for body structural parts, the high pressure and precision of the Model 3200 Bending Machine ensures the strength and stability of parts, such as body frames, support structures and other important components.

Household appliance industry

Stamping of housings and accessories

Stamping of housings and accessories is a critical process in the household appliance industry, especially in combination with the 3200 press brake, which allows higher levels of productivity and product quality to be realized. This powerful machine can cope with larger sheet metal sizes and offers a wide range of possibilities for the processing of housings and fittings for household appliances.

First of all, the 3200 bending machine can handle thicker metal sheets, such as stainless steel or aluminum alloys, which are common and widely used in the appliance industry. Employing a precise bending process, these metal sheets can be manufactured into housings and accessories that meet the design requirements. This not only improves the appearance and texture of the product but also enhances its durability and stability.

Improve product appearance and performance

In combination with the 3200 bending machine, complex shapes can be realized. Many home appliances need to have a unique design, such as curves, corners and other special shapes. This is where the high-pressure capability and precise control of the bending machine becomes especially important. Operators can accurately adjust the parameters of the bending machine according to the product design requirements, bending the metal sheet into various complex shapes, thus realizing the diversification and personalization of product appearance.

Bending and molding of sheet metal

The bending and forming of sheet metal plays an important role in the construction industry. Using equipment such as the 3200 press brake, metal sheets of different thicknesses and types can be bent and formed with precision. These processing techniques are widely used in the manufacture of building structures, such as various types of beams and columns, as well as decorative exterior panels.

Processing of building structures and decorative materials

In the construction industry, sheet metal is used to manufacture a wide range of structural and decorative materials. With machines such as the 3200 press brake, sheet metal can be cut to the desired size and shape for wall cladding, roofing, railings, stair handrails, and more. These metal products often require precise machining to ensure that they meet design requirements and have a high-quality appearance.

Overall, the bending and forming of sheet metal plays a key role in the construction industry, as well as in other industries, and modern equipment such as the 3200 press brake makes it possible to process sheet metal more accurately and efficiently, meeting the diverse needs of different industries.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.